How much raw water does a 200 m³/h ultrafiltration system consume?

In modern water treatment technology, ultrafiltration (UF) has attracted widespread attention due to its efficient solid-liquid separation ability and wide application fields. For an ultrafiltration system with a processing capacity of 200 cubic meters per hour, how much raw water does it need to consume? This is a question involving many factors.

This article will explore this issue in detail, including the working principle of the ultrafiltration system, operating efficiency, factors affecting raw water consumption, and data analysis in practical applications.

What is the basic principle of ultrafiltration system?

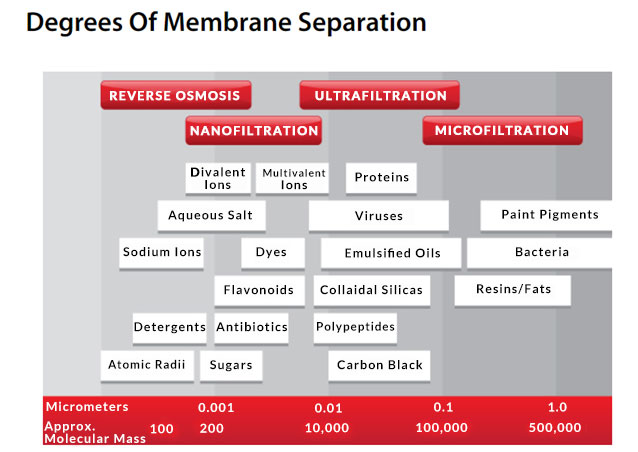

The ultrafiltration system is a pressure-driven membrane separation technology that can intercept suspended particles, bacteria, viruses, colloids and other impurities in water, while allowing water molecules and small molecular solutes to pass through. The pore size of the ultrafiltration membrane is usually between 0.01 and 0.1 microns, and its main working principle is as follows:

1. Influent pretreatment: Before the raw water enters the system, it usually needs to be pretreated to remove larger particles and organic matter and reduce the burden on the ultrafiltration membrane.

2. Ultrafiltration process: Under a certain pressure, raw water is pushed through the ultrafiltration membrane, suspended matter and microorganisms in the water are trapped on the membrane surface, and clean water passes through the membrane pores to become produced water.

3. Backwashing and chemical cleaning: In order to prevent the accumulation of pollutants on the membrane surface, the ultrafiltration system is regularly backwashed and chemically cleaned to maintain the flux and service life of the membrane.

How much raw water does a 200 cubic meter per hour ultrafiltration system consume?

Operation efficiency of ultrafiltration system:

The operation efficiency of the ultrafiltration system mainly depends on its water production rate (also called recovery rate), that is, the ratio of water production to raw water. The water production rate directly affects the consumption of raw water. Generally speaking, the water production rate of the ultrafiltration system is between 85% and 95%, which means that under ideal conditions, a 200 cubic meter per hour ultrafiltration system needs to consume 210 to 235 cubic meters of raw water.

What are the factors affecting raw water consumption?

The actual raw water consumption of the ultrafiltration system will be affected by many factors, including:

1. Raw water quality: Suspended solids, turbidity, bacterial content and other indicators in the raw water directly affect the pollution rate and cleaning frequency of the ultrafiltration membrane. Raw water with poor water quality will increase the frequency of backwashing and chemical cleaning, thereby increasing raw water consumption.

2. System design: The design parameters of the ultrafiltration system, such as membrane area, membrane module arrangement, water inlet pressure, etc., will affect the water production rate and raw water consumption of the system. Optimized design can increase water production rate and reduce raw water consumption.

3. Operation management: Including backwashing and chemical cleaning management, operator skills, etc. Good operation management can maintain the efficient operation of the system and reduce raw water consumption.

Case analysis: Raw water consumption of 200 cubic meters per hour ultrafiltration system

In order to understand more specifically how much raw water is consumed by a 200 cubic meters per hour ultrafiltration system, we can illustrate it through the following case analysis.

Case 1: A municipal water supply project

A municipal water supply project uses a 200 cubic meters per hour ultrafiltration system to treat surface water. In the early stage of the project, the turbidity of the raw water was high, and frequent backwashing and chemical cleaning were required.

● Raw water quality: turbidity is 20 NTU, and the suspended solids content is high.

● Water production rate: The initial water production rate is 85%, and after optimization and adjustment, it is stabilized at 90%.

● Raw water consumption: Initially, 235 cubic meters of raw water were consumed per hour (200 cubic meters of produced water + 35 cubic meters of backwashing and chemical cleaning water), and after optimization, the raw water consumption was about 222 cubic meters per hour (200 cubic meters of produced water + 22 cubic meters of backwashing and chemical cleaning water).

Through optimized operation and improved management, the raw water consumption of the project has been significantly reduced, and the water production rate has been increased to 90%.

Case 2: An industrial water treatment project

An industrial enterprise uses a 200 cubic meters per hour ultrafiltration system for circulating water treatment in the production process. Due to the low content of suspended solids and organic matter in industrial water, the system operates stably and the cleaning frequency is low.

● Raw water quality: low suspended solids content, turbidity is 5 NTU.

● Water production rate: stable at around 95%.

● Raw water consumption: 210.5 cubic meters of raw water per hour (200 cubic meters of produced water + 10.5 cubic meters of backwashing and chemical cleaning water).

The raw water consumption of this industrial project is low, mainly due to the good raw water quality and optimized system design, which maintains a high water production rate.

Conclusion on the 200 cubic meters per hour ultrafiltration system

Through the analysis of the basic principles, operating efficiency and influencing factors of raw water consumption of the ultrafiltration system, we can draw the following conclusions:

1. The raw water consumption of the ultrafiltration system mainly depends on its water production rate. For a 200 cubic meters per hour ultrafiltration system, the ideal water production rate is between 85% and 95%, which means that its raw water consumption is between 210 and 235 cubic meters per hour.

2. Raw water quality, system design and operation management are key factors affecting raw water consumption. Poor raw water quality, suboptimal system design and improper operation management will increase the frequency of backwashing and chemical cleaning, thereby increasing raw water consumption.

3. Data from actual applications show that raw water consumption can be significantly reduced by optimizing operations and improving management. Improving water production rate and system operation efficiency can reduce cleaning water and reduce raw water consumption.