- Commercial Reverse Osmosis Water Treatment Systems

- Industrial Reverse Osmosis Water Treatment Systems

- Ultrafiltration UF Water Treatment Systems

- Ion Exchange Water Treatment System

- Containerized Water Treatment Systems

- Customized Water Treatment System

- Bottle Water Filling Line

- Water Mechanical Micron Filters

- Stainless Steel Water Treatment Equipments

- Water Treatment Parts

- Water Sterilization

What is the cost of replacing the ro membrane in industrial seawater desalination systems?

In recent years, with the increasing demand for industrial water, industrial seawater desalination systems have received widespread attention as an important freshwater production technology. However, with the passage of system operation time, the aging and damage of reverse osmosis membranes have become important factors affecting system performance. This article will delve into the cost of replacing the reverse osmosis membrane in industrial seawater desalination systems, providing reference for scientific equipment maintenance in enterprises.

The basic functions of reverse osmosis membranes in seawater desalination systems

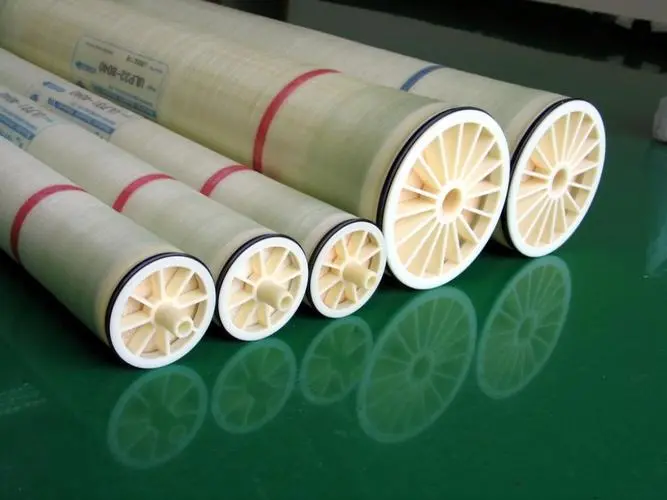

The seawater desalination system effectively removes salt and impurities from seawater through efficient filtration through reverse osmosis membranes, obtaining fresh water that meets industrial production standards. As the core component of the system, ro membrane plays an important role in filtration and separation, which directly affects the water purification effect and long-term stable operation of the system.

Factors affecting the cost of replacing reverse osmosis membranes

Reverse osmosis membrane specifications and models: Different specifications and models of reverse osmosis membranes are suitable for industrial seawater desalination systems with different capacities and requirements, and their prices vary.

Brand and quality of reverse osmosis membranes: Different brands of reverse osmosis membranes have differences in quality and performance, and high-quality membranes are usually more expensive.

Membrane performance parameters: High performance reverse osmosis membranes may have higher filtration efficiency and longer service life, but their prices are also relatively high.

Replacement service fee: If the enterprise chooses to have a professional team replace the reverse osmosis membrane, it may need to pay the corresponding service fee.

Cost of engineering and equipment shutdown: Replacing the reverse osmosis membrane may require shutdown for maintenance, which can lead to engineering and equipment shutdown, resulting in certain economic losses.

Market situation: What is the cost of replacing reverse osmosis membranes in industrial seawater desalination systems?

According to market research, there is a certain fluctuation in the cost of replacing reverse osmosis membranes in industrial seawater desalination systems within the industry. Generally speaking, the cost of replacing a single ro membrane may range from thousands to tens of thousands of yuan, depending on the comprehensive impact of the above factors.

Scientific maintenance prolongs system lifespan

Regular testing and monitoring: By regularly testing water quality and monitoring the performance parameters of reverse osmosis membranes, signs of membrane aging and damage can be detected in a timely manner.

Reasonable operation system: Strictly control the operating parameters of industrial seawater desalination system, avoid excessive water pressure and temperature, and slow down the aging rate of reverse osmosis membrane.

Regular cleaning and maintenance: Regularly use professional cleaning agents to clean the reverse osmosis membrane, remove dirt and impurities, and delay the aging of the membrane.

Reasonable selection of membranes: Choose a ro membrane with appropriate performance according to actual needs, which can not only meet industrial production requirements but also reduce replacement costs.

In the operation of industrial seawater desalination systems, the replacement of reverse osmosis membranes is an important link to ensure the long-term stable operation of the system. Through scientific maintenance and regular replacement, enterprises can maximize the lifespan of the system, improve freshwater production efficiency, and achieve a win-win situation of economy and environmental protection. Therefore, in daily management, scientific maintenance of industrial seawater desalination systems is an important measure to ensure water quality stability and equipment performance.