What are the benefits of electrodeionization to industry?

Electrodeionization (EDI) is a water treatment technology widely used in the industrial field. It removes ions and impurities in water through an electrochemical process to provide high-purity water quality. In this news release, we explore the benefits of electrodeionization to industry and its important role in environmental protection, resource recovery and water quality safety.

What are the benefits of electrodeionization to industry?

Electrodeionization technology has many benefits in industry, including:

1. No accumulation of pollutants: Traditional ion exchange beds may produce waste gas during the regeneration process, while EDI's ion exchange bed can be continuously regenerated without producing waste gas. This means they don’t create contaminant buildup like traditional ion exchange beds, keeping the production environment clean.

2. Chemical-free: Electrodeionization does not require the addition of chemicals and relies entirely on the electrochemical process to remove ions and impurities in the water. Therefore, it is a clean, safe, and environmentally friendly water treatment method.

3. Ion-free results: The electrodeionization process is very effective and can remove almost all ions in the water, making the treated water very pure. This allows the treated water to be safely used in high-risk industrial applications such as pharmaceutical production.

4. Recyclability: The ions removed through the electrodeionization process can be collected and recycled to achieve resource reuse and reduce resource waste and environmental burden.

How to implement electrodeionization technology?

Implementing electrodeionization technology generally requires the following steps and equipment:

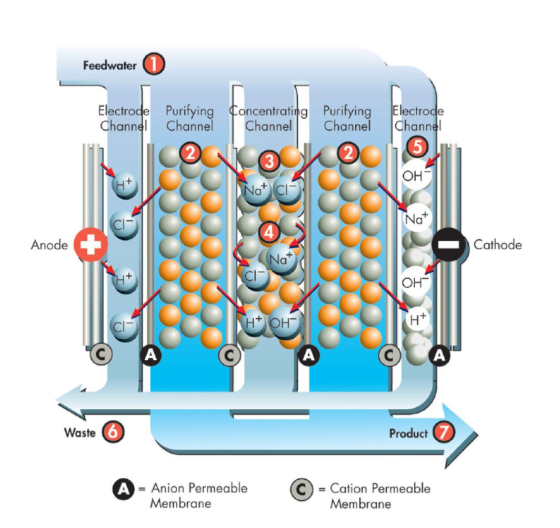

1. Electrodeionization module: An electrodeionization system usually includes multiple electrodeionization modules, each of which has an ion exchange bed and electrodes inside. As water passes through these modules, ions are exchanged and moved to the ion exchange bed, where they are adsorbed and removed by the electrodes.

2. Power supply and control system: Electrodeionization systems require power supply and control systems to provide appropriate current and voltage to facilitate the ion exchange and removal process.

3. Pretreatment equipment: Before entering the electrodeionization system, water usually needs to pass through pretreatment equipment, such as particle filters and activated carbon filters, to remove impurities such as large particles and organic matter.

4. Monitoring system: The electrodeionization system needs to monitor water quality, current, voltage and other parameters to ensure the normal operation of the system and maintain efficient deionization effects.

Which industrial fields use electrodeionization technology?

Electrodeionization technology is widely used in industry, mainly including the following aspects:

1. Electronic manufacturing industry: In electronic manufacturing industry, high-purity water is a very important raw material. Electrodeionization technology can provide water of sufficient purity for semiconductor production and other electronic product manufacturing processes.

2. Pharmaceutical industry: The pharmaceutical industry has very strict requirements on water quality. Electrodeionization technology can provide high-purity water that meets pharmaceutical production standards for pharmaceutical production and water for injection.

3. Chemical production: In chemical production, high-purity water is needed to prepare solutions, flush equipment, and adjust reaction conditions. Electrodeionization technology can meet these needs.

4. Electric power industry: In the electric power industry, high-purity water is needed to prepare cooling water and boiler feed water. Electrodeionization technology can provide suitable water quality to ensure the normal operation of equipment.

5. Food and beverage industry: In the production process of food and beverage, a large amount of water resources are used, so the requirements for water quality are also very high. EDI technology can provide safe and reliable water resources and ensure product quality and safety.

What are the problems with electrodeionization technology?

Although electrodeionization technology has many advantages in industrial applications, it also faces some problems:

1. High cost: The equipment and maintenance costs of EDI technology are relatively high, which may be unaffordable for some small and medium-sized enterprises.

2. Operation stability issues: During long-term operation, EDI equipment may malfunction or degrade in performance, requiring regular maintenance and inspection, which increases operating costs and workload.

3. Wastewater treatment issues: Although EDI technology can efficiently purify water resources, a certain amount of wastewater will be produced during the reverse osmosis membrane regeneration process, which needs to be properly treated to reduce the impact of environmental pollution.

4. Technology standardization and promotion issues: At present, there are still certain difficulties in the standardization and promotion of EDI technology. Research and development need to be further strengthened to promote the popularization and application of technology.

Summarize

As an efficient and environmentally friendly water treatment technology, electrodeionization technology plays an important role in the industrial field, providing high-purity water quality for industrial production, while reducing dependence on chemical substances, reducing production costs, and realizing resource utilization. sustainable use. With the advancement of science and technology and the continuous expansion of application fields, electrodeionization technology will play a more important role in the future.