What is an industrial reverse osmosis water filtration system?

Industrial reverse osmosis water filtration systems play an important role in modern industrial production, especially for industries with high requirements for water quality, such as electronic manufacturing, pharmaceuticals, food and beverage, and chemicals.

This article will explore in depth what an industrial reverse osmosis water filtration system is, its working principle, key components, application scenarios, and service life.

What is an industrial reverse osmosis water filtration system?

Industrial reverse osmosis (RO) water filtration system is a device that uses reverse osmosis membrane technology to remove impurities such as dissolved salts, organic matter, microorganisms, and heavy metals in water, providing a high-purity water source. Reverse osmosis technology applies high pressure to make water pass through a semipermeable membrane, filter out impurities, and achieve the purpose of purifying water quality. Industrial reverse osmosis systems are often used in industrial production processes that require ultrapure water or high-quality water.

What is the working principle of an industrial reverse osmosis water filtration system?

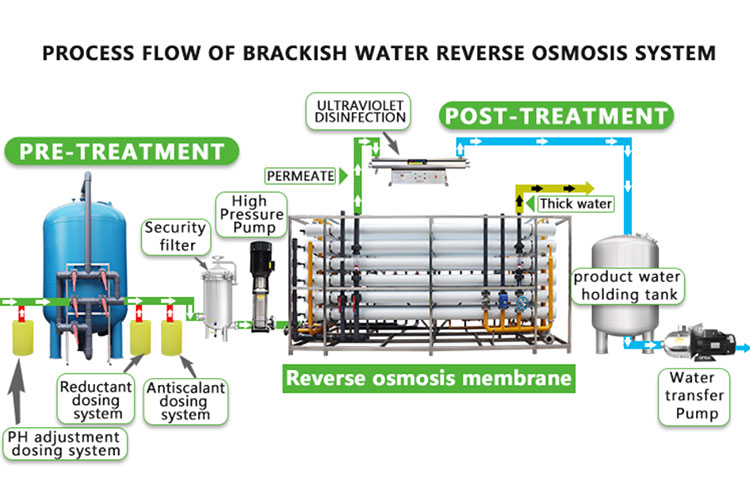

Reverse osmosis (RO) is a process that purifies water by applying reverse pressure to make water molecules pass through a semipermeable membrane, while impurities and dissolved solids are retained on the other side of the membrane. The main working principle of the reverse osmosis water filtration system includes the following steps: pretreatment → pressurization → reverse osmosis filtration → water production and concentrated water discharge → post-treatment.

1. Pretreatment:

● Mechanical filtration: remove large suspended solids and sediment in the water.

● Activated carbon adsorption: remove organic matter, residual chlorine and odor in the water.

● Softening treatment: remove calcium and magnesium ions in the water to prevent reverse osmosis membrane scaling.

2. Pressurization:

● Apply pressure through a high-pressure pump to pass water through the reverse osmosis membrane. The pressure is usually between 2 and 10 atmospheres, and the specific value depends on the inlet water quality and system design.

3. Reverse osmosis filtration:

● Reverse osmosis membrane: The semipermeable membrane is the core component of the reverse osmosis system, with a pore size of about 0.0001 microns, allowing only water molecules to pass through. The membrane is usually made of polyamide composite membrane with high efficiency filtration capacity.

4. Water production and concentrated water discharge:

● Water production: The purified water is collected for industrial production.

● Concentrated water: water with high concentration of impurities is discharged or recycled.

5. Post-treatment:

● Ultraviolet disinfection: ensure that microorganisms in the water are completely eliminated and the water quality is safe.

● pH adjustment: adjust the pH value of the produced water according to specific requirements to ensure that it is suitable for industrial use.

What are the key components of industrial reverse osmosis water filtration system?

The key components of industrial reverse osmosis water filtration system are: reverse osmosis membrane, high-pressure pump, pretreatment equipment, control system, pipelines and accessories.

1. Reverse osmosis membrane:

● The reverse osmosis membrane is the core component of the system and determines the efficiency and quality of filtration. Commonly used reverse osmosis membranes include roll membranes, tubular membranes and flat membranes.

2. High-pressure pump:

● The high-pressure pump provides the necessary pressure for the reverse osmosis process and is an important equipment to ensure that water passes through the membrane. The selection of the pump needs to consider factors such as water inlet, system pressure and energy consumption.

3. Pretreatment equipment:

● Including mechanical filters, activated carbon filters and softening equipment, etc., to ensure that the water quality entering the reverse osmosis membrane meets the requirements and extend the service life of the membrane.

4. Control system:

● Including pressure sensors, flow meters and automatic controllers, etc., real-time monitoring and adjustment of system operating parameters to ensure stable operation of the system.

5. Pipes and accessories:

● High-quality pipes and accessories are the basis for ensuring long-term stable operation of the system, and must have characteristics such as corrosion resistance and high pressure resistance.

What are the application scenarios of industrial reverse osmosis water filtration systems?

Application scenarios of industrial reverse osmosis water filtration systems: electronic manufacturing, pharmaceutical industry, food and beverage, power and energy, chemical industry.

1. Electronic manufacturing:

● The production process of semiconductors and liquid crystal displays requires extremely high-purity water. The ultrapure water provided by the industrial reverse osmosis system can meet this demand and ensure product quality and stable production process.

2. Pharmaceutical industry:

● The pharmaceutical process has strict requirements on water quality, especially water for injection and purified water. The industrial reverse osmosis system can effectively remove impurities and microorganisms in the water to ensure the safety and effectiveness of drugs.

3. Food and beverage:

● Food and beverage production has strict requirements on water quality. The high-quality water source provided by the industrial reverse osmosis system can improve the taste and safety of the product and meet the needs of consumers.

4. Power and Energy:

● The power and energy industry requires high-quality boiler water and cooling water. Industrial reverse osmosis systems can effectively remove dissolved solids and hardness ions in water, prevent equipment scaling and corrosion, and extend the service life of equipment.

5. Chemical Industry:

● The chemical production process requires water of different purities. Industrial reverse osmosis systems can flexibly adjust the quality of produced water to meet various process requirements and improve production efficiency and product quality.

What is the service life of an industrial reverse osmosis water filtration system?

Service life of an industrial reverse osmosis water filtration system: The service life of a reverse osmosis membrane is usually 2 to 5 years, the service life of a high-pressure pump is usually between 5 and 10 years, the service life of a pretreatment equipment is between 5 and 10 years, the service life of a control system is usually more than 10 years, and the service life of high-quality pipes and accessories is usually more than 15 years.

1. Service life of a reverse osmosis membrane:

The service life of a reverse osmosis membrane is usually 2 to 5 years, depending on the quality of the influent water, the pretreatment effect, and the operation and maintenance. Regular cleaning and replacement of reverse osmosis membranes is the key to ensuring long-term and efficient operation of the system.

2. Life of high-pressure pump:

The life of high-pressure pump is usually between 5 and 10 years. Regular maintenance and correct operation can extend the service life of the pump. The selection of pumps should be based on system requirements, and high-quality, durable products should be selected.

3. Life of pretreatment equipment:

The life of pretreatment equipment such as mechanical filters, activated carbon filters and softening equipment is usually between 5 and 10 years, depending on the frequency of use and maintenance. Regular replacement of filter media and resins is the key to ensuring the pretreatment effect.

4. Life of control system:

The life of control system is usually more than 10 years. Advanced automatic controllers and sensors can effectively extend the service life of the system. Regularly calibrate and maintain the control system to ensure its stable operation.

5. Life of pipes and fittings:

The life of high-quality pipes and fittings is usually more than 15 years. Selecting corrosion-resistant and high-pressure resistant materials can extend the overall life of the system. Regularly inspect and maintain pipes and fittings to prevent leakage and damage.

Summary of Industrial Reverse Osmosis Water Filtration System

As an indispensable and important equipment in modern industrial production, the industrial reverse osmosis water filtration system provides high-quality water sources by efficiently removing impurities and pollutants in water, ensuring the stability of the production process and product quality. Understanding its working principle, key components, application scenarios and service life will help to better select and use industrial reverse osmosis systems and improve industrial production efficiency and water quality safety. In actual applications, paying attention to equipment maintenance and water quality monitoring is the key to ensuring the long-term and efficient operation of industrial reverse osmosis water filtration systems.