What is a water filtration system for industrial processes?

Water filtration systems in industrial processes play an important role in various industries. They are not only used in the final process but also play a vital role in the production process. This article will take an in-depth look at what water filtration systems in industrial processes are, as well as their application and importance in various industries.

What is a water filtration system for industrial processes?

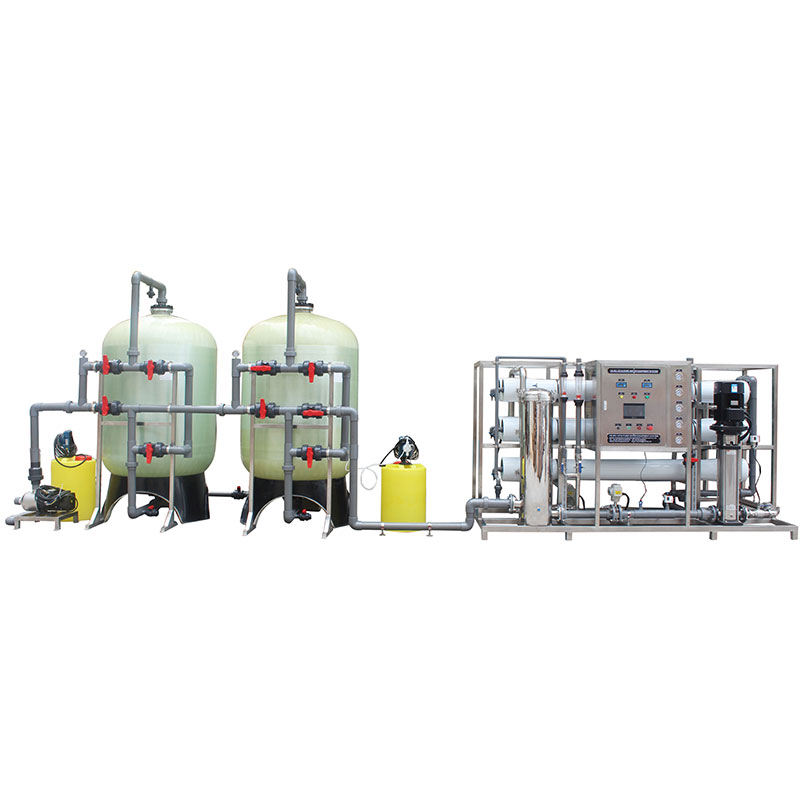

A water filtration system in industrial processes is a device or device used to remove suspended solids and other impurities from liquids. They can use different filter media and working principles, such as physical filtration, chemical filtration and biological filtration, etc., to ensure the purity and suitability of water quality. These systems usually consist of multiple components, including filtration media, filters, pumps, and control systems, and can be custom designed according to different process requirements.

Water filtration systems in industrial processes are not only used in the production of final products, but are also widely used in various stages of the production process, including raw material handling, reactor cooling, equipment cleaning, and wastewater treatment. They can help improve production efficiency, protect equipment, and reduce waste and pollutant emissions, thereby reducing production costs, improving product quality, and complying with environmental regulations.

What are the applications of water filtration systems in industrial processes in the food and beverage industry?

In the food and beverage industry, water filtration systems play a vital role and are mainly used in raw material processing, production equipment flushing, product cleaning, and wastewater treatment:

1. Raw material processing: Food and beverage production requires a large amount of water as raw material, and the quality of water directly affects the quality and taste of the product. The water filtration system can remove impurities and harmful substances from the water to ensure the purity and safety of the raw materials.

2. Production equipment flushing: Production equipment needs to be cleaned and disinfected regularly to prevent bacterial and microbial contamination. The water filtration system can provide high-purity cleaning water, protect production equipment, and ensure product hygiene and safety.

3. Product cleaning: Food and beverage products need to be cleaned and disinfected during the production process to ensure product quality and hygiene. Water filtration systems can provide clean and sterile water sources, ensuring product safety and consistency.

4. Wastewater treatment: A large amount of wastewater is generated during the production of food and beverages, which needs to be treated and disposed to prevent environmental pollution. The water filtration system can remove harmful substances from wastewater, realize resource utilization of wastewater, and reduce the impact on the environment.

The food and beverage industry has very strict requirements on water quality, and water filtration systems can provide high-purity water sources to meet production needs and ensure product quality and safety.

How do water filtration systems in industrial processes function in other industries?

In addition to the food and beverage industry, water filtration systems in industrial processes also play an important role in other industries, mainly in the pulp and paper industry, the oil and gas industry, the chemical and pharmaceutical industry, and the power and electronics industry. :

1. Pulp and paper industry: The pulp and paper making process requires a large amount of clean water for pulp production, paper processing and equipment cleaning. Water filtration systems can remove impurities and fibers from water, protect equipment, and improve paper quality and production efficiency.

2. Oil and natural gas industry: The oil and natural gas extraction process requires a large amount of water for drilling, flushing and water injection. Water filtration systems can remove sediments and organic matter from the water, protect equipment, and improve mining efficiency and resource utilization.

3. Chemical and pharmaceutical industry: Pure water is needed in the chemical and pharmaceutical production process for raw material processing, reactor cooling and product washing. Water filtration systems can provide high-purity water sources, ensure product quality and safety, and meet the strict requirements of the industry.

4. Power and electronics industry: The power and electronics production process requires large amounts of water for power generation, equipment cooling, and electronic component manufacturing. Water filtration systems can remove ions and microorganisms from water, protect equipment, and improve production efficiency and product quality.

In summary, water filtration systems in industrial processes play an important role in various industries, providing reliable water sources for production and ensuring product quality and safety.