What are the methods for industrial water purification?

With the acceleration of industrialization, the purification and treatment of industrial water have become particularly important. This article will explore industrial water purification methods, including nanofiltration and reverse osmosis, as well as their principles and scope of application, aiming to help readers better understand the current status and development trends of industrial water treatment technology.

What are the methods for industrial water purification?

There are a variety of methods for industrial water purification, with two major treatment methods including nanofiltration and reverse osmosis:

1. Nanofiltration

Nanofiltration is a method of removing microorganisms, bacteria and some dissolved solids from water through a semipermeable membrane. Its working principle is based on the fact that the membrane pore size is smaller than the size of microorganisms and bacteria, but larger than the size of water molecules, so it can effectively filter organic matter and microorganisms in the water. Nanofiltration is mainly used to remove microorganisms and hardness from water and can provide a relatively clean water source.

2. Reverse Osmosis

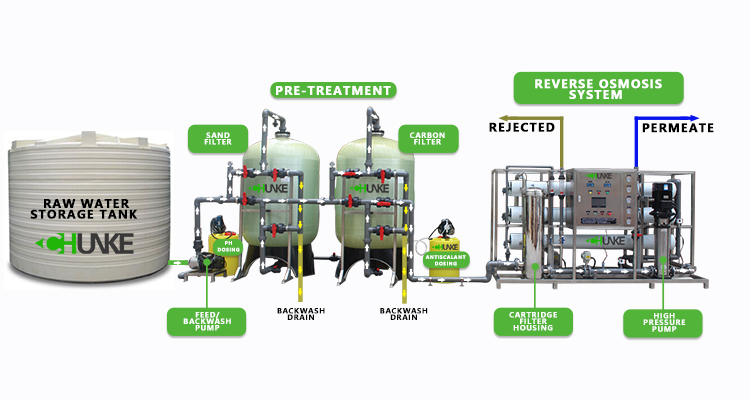

Reverse osmosis is a more thorough method of industrial water treatment that uses high pressure to drive water through a semipermeable membrane to separate water molecules from dissolved solids and other impurities. This method can effectively remove most dissolved solids from water, including salts, heavy metals, etc. The water after reverse osmosis treatment is clean and can be used for a wider range of industrial production and domestic water.

How do nanofiltration and reverse osmosis work?

★The working principle of nanofiltration: Nanofiltration uses the tiny pores of the semipermeable membrane to block bacteria, microorganisms and most dissolved solids in the water, preventing them from passing through the membrane surface, thereby achieving filtration and purification of water. This method does not require high pressure and is suitable for industrial production with lower water quality requirements.

★How reverse osmosis works: Reverse osmosis uses high pressure to force water through a semipermeable membrane, allowing water molecules to pass through the membrane pores, while dissolved solids and other impurities are left on the membrane surface. This method requires higher energy input, but can more thoroughly remove impurities from the water and produce higher quality purified water.

What are the advantages and disadvantages of nanofiltration and reverse osmosis?

Nanofiltration and reverse osmosis are two methods of industrial water purification, each with its own advantages and disadvantages.

The advantages of nanofiltration are simple operation, low equipment cost, low water quality requirements, and it can be suitable for some small and medium-sized industrial production scenarios. However, nanofiltration technology can only remove a part of the pollutants in water, and is less effective at removing some tiny particles and dissolved solids.

In contrast, reverse osmosis technology can more thoroughly remove contaminants from water, producing purer water. However, reverse osmosis equipment has high costs, complex operations, high energy consumption, and high maintenance and management costs. It is suitable for large-scale industrial production scenarios with high water quality requirements.

What are the application areas of nanofiltration and reverse osmosis?

★Application scope of nanofiltration: Nanofiltration is suitable for industrial production that does not have strict water quality requirements, such as pharmaceuticals, chemicals and other fields. It can remove microorganisms and organic matter from the water, providing a relatively clean water source, but it cannot completely remove dissolved solids.

★Application scope of reverse osmosis: Reverse osmosis is suitable for occasions with high water quality requirements, such as electronic manufacturing, beverage production, etc. It can completely remove dissolved solids and heavy metals from water, produce high-purity purified water, and has a wider range of applications.

By selecting appropriate industrial water treatment methods, the water quality requirements in different industrial production processes can be effectively met and the smooth progress of production can be ensured.

Summarize

Industrial water purification methods include two main technologies: nanofiltration and reverse osmosis. Nanofiltration is suitable for situations with less stringent water quality requirements, while reverse osmosis is suitable for situations with higher water quality requirements.

Choosing the appropriate treatment method can effectively improve water resource utilization efficiency and ensure the smooth progress of industrial production. With the continuous advancement of technology and the continuous expansion of applications, industrial water treatment technology will usher in a broader development space.