What is the Difference Between Commercial and Industrial Water Filters?

Water filtration systems play an important role in both commercial and industrial sectors, ensuring water quality and safety. Commercial and industrial water filters vary in design, purpose and performance to meet the needs of different industries and organizations. In this article, we will explore the differences between commercial and industrial water filters in detail and analyze the characteristics and application range of each.

Differences Between Commercial and Industrial Water Filters:

There are clear differences in design and purpose between commercial and industrial water filters.

Commercial water filtration systems are commonly used in medical facilities, laboratories, hotels, manufacturing plants, schools, restaurants and other institutions that require large amounts of water. These systems are designed to provide high quality water to meet the needs of these sites for drinking, cooking, cleaning and other uses.

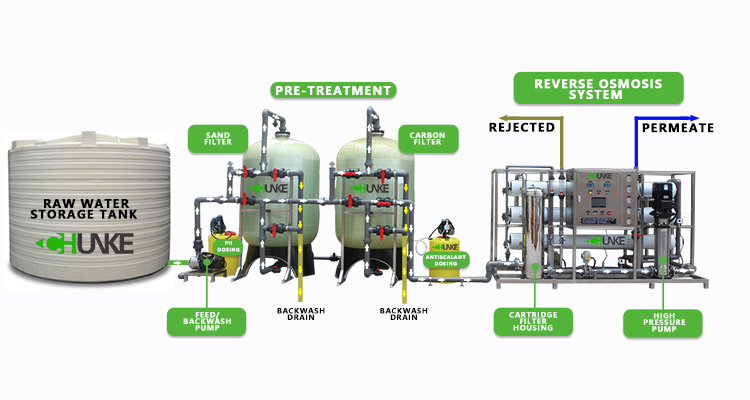

Industrial water filters are commonly used for water treatment in industrial processes such as manufacturing, chemical plants, mining and power plants. The main working principle of industrial water filters is to remove particles from water or waste streams. These filters industrial water filters are larger in size and capable of handling large volumes of water or wastewater. These systems typically employ different types of filters, such as sand, carbon, and membrane filters, to remove suspended solids, heavy metals, and other impurities.

Features of commercial water filtration systems include: versatility, efficiency, reliability, and customizability.

1. Versatility: Commercial water filters can often remove a variety of impurities simultaneously, including suspended solids, heavy metals, chemical contaminants, and microorganisms.

2. Efficiency: These systems are designed to treat large volumes of water and thus maintain high efficiency while purifying water quality.

3. Reliability: Commercial water filtration systems usually use advanced technology and materials to ensure the stability and reliability of the system.

4. Customizable: Commercial water filtration systems can be customized according to the specific needs of customers to meet the requirements of specific industries and sites.

Industrial water filter features include: high volume treatment, suspended solids removal, durability, and a variety of filter options.

1. High volume processing: Industrial water filters are usually able to handle large amounts of water flow and adapt to the needs of industrial production.

2. Removal of suspended solids: These filters are mainly used to remove suspended solids from water to ensure water clarity and quality.

3. Durability: Industrial water filters are typically designed to be durable and able to withstand high pressures and harsh working environments.

4. Various filter options: Depending on specific needs, industrial water filters can use different types of filters, such as sand filters, membrane filters, etc.

What types and applications are there for commercial water filters?

Commercial water filters can be divided into 5 types based on their purpose and the type of impurities they need to remove.

Commercial water filter types include: activated carbon filters, reverse osmosis systems, ultrafiltration systems, UV sterilizers, and ion exchangers.

1. Activated carbon filter: This filter is widely used to remove chemical contaminants, odors and colors from water. Activated carbon filters are commonly found in places like restaurants, hotels and hospitals.

2. Reverse osmosis system: Reverse osmosis system can remove dissolved solids, heavy metals and chemical contaminants from water, providing high-quality drinking water for commercial premises.

3. Ultrafiltration system: Ultrafiltration system can remove microorganisms and suspended solids from water and is suitable for medical institutions and laboratories.

4. Ultraviolet sterilizer: Ultraviolet sterilizer can effectively kill bacteria and viruses in water and is widely used in the medical and food processing industries.

5. Ion exchanger: Ion exchanger is used to remove hardness and heavy metals from water, providing softening and purifying effects for commercial water.

Applications for commercial water filters include: healthcare facilities, hotels and restaurants, schools and universities, manufacturing plants, and office and commercial buildings.

1. Healthcare facilities: Hospitals and clinics require high-quality water for medical equipment, cleaning and drinking.

2. Hotels and Restaurants: Hotels and restaurants require purified water for cooking, cleaning and drinking water.

3. Schools and Colleges: Schools and colleges require purified water for drinking and other purposes.

4. Manufacturing plants: Manufacturing plants require purified water for production processes and equipment cleaning.

5. Office and commercial buildings: These locations require purified water for drinking and cleaning purposes.

Industrial Water Filter Application and Maintenance

Industrial water filters play an important role in industrial production processes, ensuring that water quality meets standards and protecting production equipment and processes.

Applications for industrial water filters include: manufacturing, energy industry, petrochemical industry, pharmaceutical industry and food processing industry.

1. Manufacturing: Manufacturing requires purified water for production, cooling and cleaning.

2. Energy Industry: The energy industry requires purified water for use in power generation and cooling systems.

3. Petrochemical industry: The petrochemical industry requires purified water for production processes and equipment cleaning.

4. Pharmaceutical Industry: The pharmaceutical industry requires purified water for production and cleaning.

5. Food processing industry: The food processing industry requires purified water for production and cleaning.

In order to ensure the long-term stable operation of industrial water filters, maintenance is crucial.

The key methods to maintain industrial water filters are: regular replacement of filter media, cleaning of filters, monitoring of water quality, checking of system pressure and regular maintenance inspections

1. Regularly replace the filter material: According to usage, regularly replace the filter material in the filter to maintain the filtration effect.

2. Clean the filter: Clean the filter regularly to remove accumulated impurities and ensure smooth water flow.

3. Monitor water quality: Monitor water quality regularly to ensure compliance with industry standards and requirements.

4. Check the system pressure: Make sure the system pressure is within the normal range to avoid high or low pressure affecting the performance of the filter.

5. Regular maintenance inspections: Conduct comprehensive inspections of the system regularly to ensure that all components are functioning properly.

Summary: Commercial and industrial water filters play an important role in different fields to ensure that water quality reaches standards and provide safe and clean water for people and industrial production. By understanding the differences, types, and applications of commercial and industrial water filters, and how to maintain these systems, we can better utilize water filtration technology to improve the quality of life and production.