What is the role of marine reverse osmosis? How long is its service life?

As the global water crisis intensifies, marine reverse osmosis technology (MRO) has gradually become an important means to solve the problem of fresh water shortage. Especially in coastal and island areas, the application of marine reverse osmosis provides valuable fresh water resources for local residents and industries.

However, as a device that operates for a long time in a harsh marine environment, what is the role of a marine reverse osmosis machine? How long can it be used in a harsh marine environment? This article will explore these issues in depth.

What is the role of a marine reverse osmosis machine?

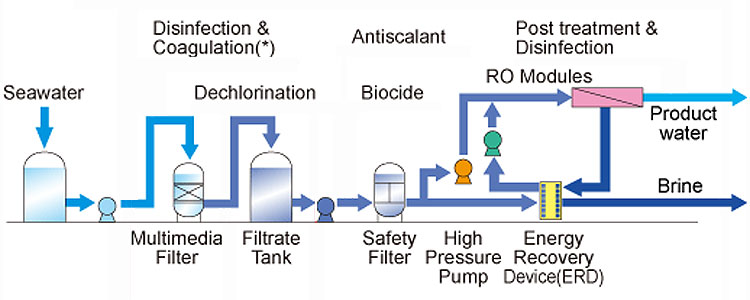

Marine reverse osmosis machines are mainly used to convert seawater into drinkable fresh water. Its core technology is to filter seawater under high pressure through a semi-permeable membrane, separate salt and other impurities in the water, and produce clean fresh water. This technology has been widely used in ships, offshore platforms, coastal cities, industrial parks and other fields. The following are the main functions of marine reverse osmosis machines:

1. Fresh water supply for ships and offshore platforms

Fresh water supply has always been an important issue in sea voyages or operations far away from land. Traditional methods such as carrying enough fresh water or rainwater collection systems often cannot meet long-term needs. Marine reverse osmosis machines provide ships and offshore platforms with a reliable supply of fresh water, greatly improving the autonomy of navigation and operations and reducing dependence on fresh water resources on shore.

2. Fresh water supply for coastal cities and islands

For coastal cities and islands with scarce water resources, marine reverse osmosis machines are an effective means to solve the problem of drinking water. Through seawater desalination, these areas can obtain sufficient drinking water supply and avoid the living and economic difficulties caused by water shortages. Especially in dry seasons or peak tourist seasons, marine reverse osmosis machines can ensure a continuous supply of water.

3. Industrial water treatment

Many industrial processes require a large amount of high-purity water, such as electronics, chemicals, pharmaceuticals and other industries. Marine reverse osmosis machines can not only provide drinking water, but also produce high-purity water that meets industrial needs. After further treatment, this water can be used for boiler feed water, cooling water, cleaning water and other purposes to ensure the normal operation of industrial production.

4. Emergency water source guarantee

In natural disasters or other emergencies, marine reverse osmosis machines can be used as emergency water source guarantee equipment. Whether after a tsunami, hurricane or earthquake, marine reverse osmosis machines can be quickly deployed to provide safe drinking water to disaster areas and help restore basic living conditions.

Challenges of the marine environment to reverse osmosis machines

Despite the importance of marine reverse osmosis machines, the operation of equipment faces many challenges in harsh marine environments. These challenges include high-salinity seawater, highly corrosive marine atmosphere, continuous wave impact, and biological attachment.

1. High salinity and mineral deposition

The salinity of seawater is about 3.5%, and it contains a large amount of minerals such as sodium chloride, magnesium sulfate, and calcium carbonate. During the marine reverse osmosis process, these minerals will form deposits on the membrane surface, resulting in decreased membrane permeability and reduced filtration efficiency. If the membrane is not cleaned or replaced in time, the service life of the equipment will be greatly shortened.

2. Marine atmospheric corrosion

Factors such as salt spray, humidity, and wind in the marine environment are extremely corrosive to the metal parts of the equipment. Even reverse osmosis machines made of highly corrosion-resistant materials still face corrosion problems when exposed to the marine environment for a long time. This will not only affect the appearance of the equipment, but also cause damage to key components and affect overall performance.

3. Biofouling and marine fouling

Organisms such as microorganisms, algae and shellfish in the ocean easily adhere to the water inlet, pipes and membrane surfaces of the reverse osmosis machine, forming marine fouling. This biofouling will not only clog the system, but also increase the difficulty of equipment maintenance, further shortening the service life.

4. Mechanical wear and fatigue

The continuous impact of waves and the long-term operation of equipment will cause wear and fatigue of mechanical parts. Especially on offshore platforms or harsh marine environments, the pumps, bearings, valves and other components of the reverse osmosis machine need to withstand high-intensity operating pressure, which puts higher requirements on the mechanical structure of the equipment.

Facing the marine environment, how long is its service life?

In the marine environment, the service life of the reverse osmosis machine depends on many factors, including the design and manufacturing quality of the equipment, the frequency and quality of maintenance, and the specific operating environment. Generally speaking, the service life of the marine reverse osmosis machine is between 10-15 years, but in some extreme environments, its life may be shortened to 5-7 years. The following are the main factors affecting the service life:

1. Equipment materials and design quality

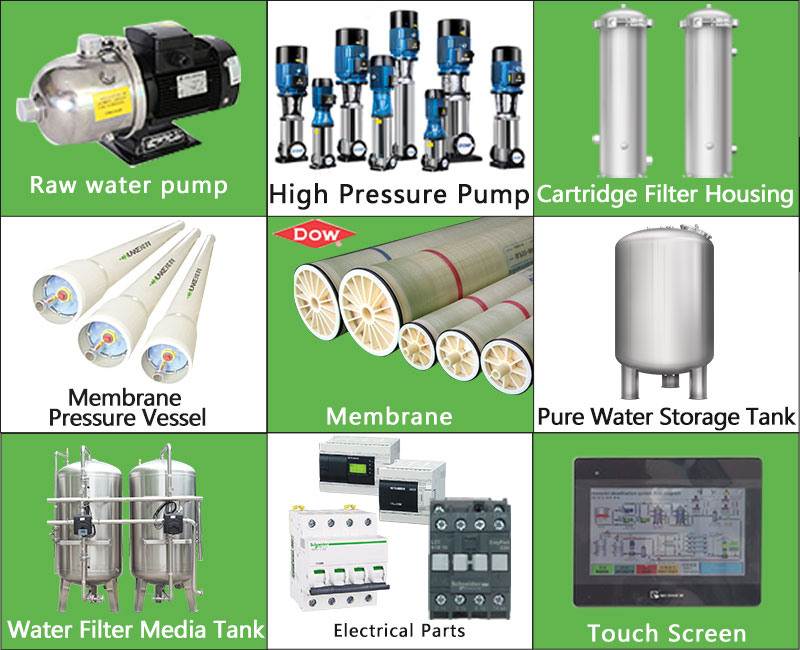

High-quality materials and scientific design are the basis for ensuring the service life of the reverse osmosis machine. In order to cope with the challenges of the marine environment, manufacturers usually choose highly corrosion-resistant materials such as stainless steel, titanium alloy, etc., and adopt anti-corrosion coating technology. In addition, the optimized design can reduce the stress concentration points of the equipment and reduce the wear of mechanical parts.

2. Maintenance

Regular maintenance is the key to extending the service life of the reverse osmosis machine. Maintenance includes regular cleaning of membrane components, inspection and replacement of wearing parts, monitoring of equipment operating status, etc. Good maintenance can prevent the occurrence of problems such as mineral deposition, corrosion and biological adhesion, and ensure the efficient operation of the equipment.

3. Operating environment

The harshness of the operating environment directly affects the service life of the reverse osmosis machine. In a mild marine environment, the equipment has relatively few corrosion and biological adhesion problems, and the service life may be longer. In harsh environments such as high salinity, high temperature and strong waves, the life of the equipment will be greatly shortened.

4. Operating specifications

Correct operating specifications can avoid excessive wear and failure of the equipment. For example, controlling the pressure and flow of the inlet water, avoiding long-term operation of the equipment under high load, and avoiding sudden water hammer effects are all important measures to extend the life of the equipment.

How to extend the service life of the marine reverse osmosis machine?

In order to extend the service life of the marine reverse osmosis machine, in addition to selecting high-quality equipment and regular maintenance, the following measures can also be taken:

1. Optimize operating conditions

By adjusting the operating parameters of the equipment, such as reducing the salinity and mineral content of the influent, the load on the membrane can be reduced and the formation of sediment can be reduced. In addition, avoiding long-term operation of the equipment at high temperature, high pressure and high flow rate can also help extend the life.

2. Use anti-corrosion technology

During the manufacture and installation of the equipment, the use of advanced anti-corrosion technologies such as electrochemical protection and corrosion-resistant coatings can effectively reduce the corrosion of the marine environment to the equipment. At the same time, regular anti-corrosion maintenance, such as repairing and updating the coating, can also help extend the service life of the equipment.

3. Install pretreatment devices

In the marine reverse osmosis system, installing pretreatment devices such as filters, degassing devices and sterilization devices can reduce mineral deposition and biological attachment, and protect the permeability and service life of the membrane. The pretreatment device can also improve the operating efficiency of the overall system and reduce energy consumption.

4. Implement automated monitoring

Through the automated monitoring system, the operating status of the equipment can be monitored in real time, such as parameters such as pressure, flow, temperature, salinity, etc. Once an abnormal situation occurs, the system will automatically alarm or take protective measures to prevent the equipment from being damaged due to failure or overload operation.

Summary

As an important equipment to solve the problem of fresh water supply in the marine environment, the role of marine reverse osmosis machine cannot be ignored. Whether on ships, offshore platforms, or in coastal cities and industrial areas, marine reverse osmosis machines provide humans with reliable fresh water resources. However, under the multiple challenges of the marine environment, the service life of the reverse osmosis machine is also facing a test.

Generally speaking, the service life of a marine reverse osmosis machine is between 10-15 years, but its specific life is affected by many factors such as equipment quality, maintenance, operating environment and operating specifications. By selecting high-quality equipment, optimizing operating conditions, using anti-corrosion technology and installing pretreatment devices, the service life of the equipment can be effectively extended to ensure its long-term and stable operation in the marine environment.

Despite the harsh marine environment, through scientific management and technical means, people can maximize the role of marine reverse osmosis machines to meet the growing demand for fresh water. In the future, with the advancement of technology and the accumulation of experience, the life and efficiency of marine reverse osmosis machines are expected to be further improved, providing stronger guarantees for human survival and development in the ocean.