What is a drum filter for wastewater treatment?

Rotary Drum Filter is a mechanical filtration equipment widely used in sewage treatment plants. It can effectively remove suspended solids, sludge and particulate matter in wastewater, significantly improve water quality, and make it meet discharge or reuse standards.

This article will introduce in detail the definition, working principle, components, and application and advantages of drum filters in sewage treatment.

What is a drum filter?

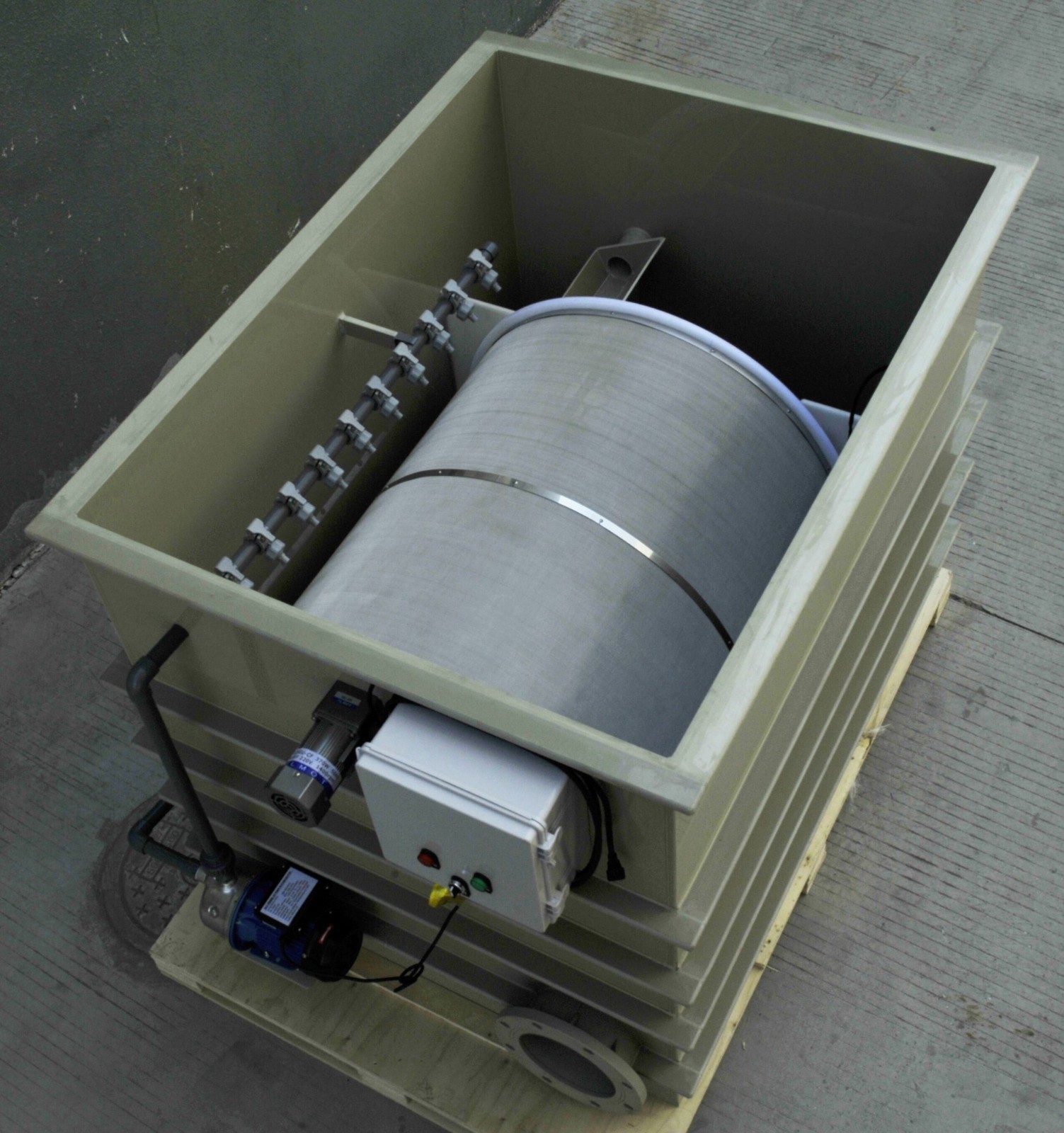

A rotating drum filter is a device that uses a rotating filter drum for solid-liquid separation. It mainly consists of a rotating drum with filter media, drive device, backwash system and housing. The drum filter traps solid particles in the wastewater on the surface of the filter drum through mechanical filtration, and removes the trapped impurities through the backwash process, thereby achieving continuous filtration.

How does a drum filter work?

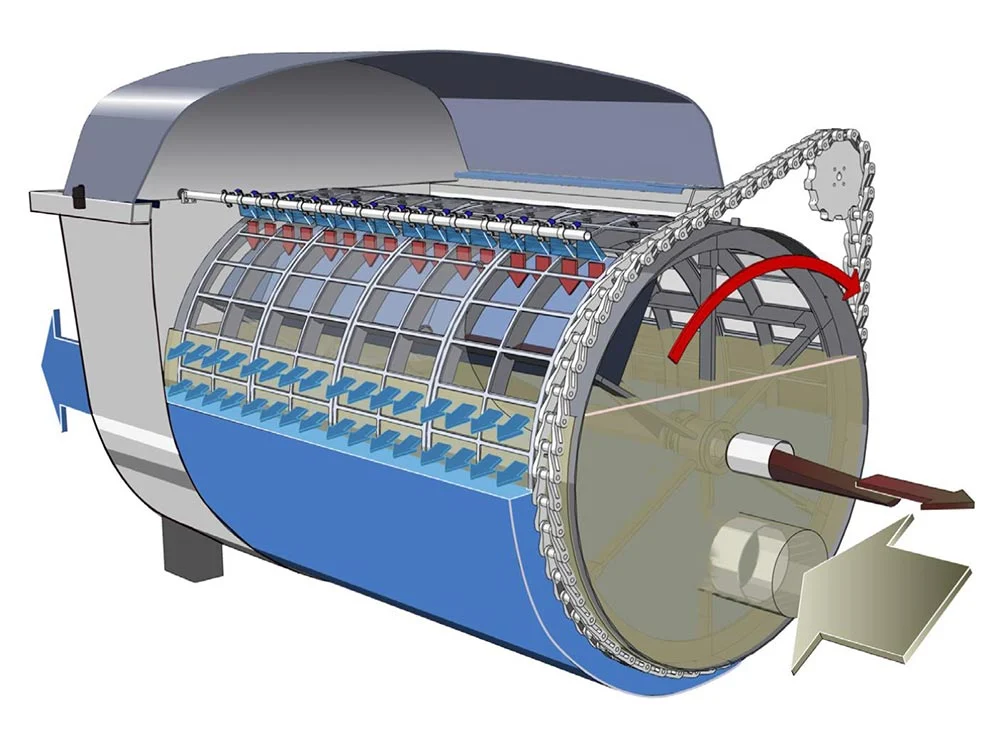

The working principle of the drum filter is based on the mechanism of combining physical filtration and backwashing. Its operation process can be divided into 4 stages: water inlet stage → filtration stage → interception stage → backwash stage. The details are as follows:

1. Water ingress stage:

Wastewater enters the drum filter from the water inlet and is evenly distributed on the outer surface of the rotating filter drum. The filter drum is usually made of stainless steel or synthetic fiber materials and has good mechanical strength and corrosion resistance.

2. Filtering stage:

As the filter drum rotates, the wastewater passes through the filter media on the outer surface of the filter drum, and the solid suspended solids in the water are trapped on the outer surface of the filter drum, while the clean filtered water enters the interior through the filter drum and is discharged from the water outlet. The rotation speed of the drum and the pore size of the filter media can be adjusted according to the water quality and treatment requirements of the wastewater.

3. Interception stage:

As the filtration process proceeds, the suspended solids on the surface of the filter drum gradually accumulate to form a filter cake. In order to maintain filtration efficiency and flow rate, drum filters are usually equipped with automatic monitoring systems to detect the accumulation of solids on the drum surface.

4. Backwash stage:

When the solid suspended matter on the surface of the filter drum accumulates to a certain extent, the system will start the backwash process. The backwash water is sprayed to the surface of the filter drum at high pressure through the nozzle to remove the trapped solid suspended matter and discharge it through the sewage outlet. The backwash process is performed while the filter drum rotates and does not affect the continuous operation of the filter.

What are the components of a drum filter?

A complete drum filter system usually includes the following five main parts: filter drum, driving device, backwash system, control system, and housing. The details are as follows:

1. Filter drum:

The filter drum is the core component of the rotary drum filter. It is usually made of stainless steel or synthetic fiber materials and has good mechanical strength and corrosion resistance. The surface of the filter drum is covered with filter media, and the pore size can be selected according to needs.

2. Drive device:

The driving device is used to drive the filter drum to rotate, usually using a transmission system composed of an electric motor and a reducer. The rotation speed of the drive unit can be adjusted according to the filtration needs to optimize the filtration effect and operating efficiency.

3. Backwash system:

The backwash system includes high-pressure water pumps, backwash nozzles and piping systems. The high-pressure water pump provides backwash water, and the nozzle sprays high-pressure water evenly onto the surface of the filter drum to remove accumulated solid suspended matter.

4. Control system:

The control system includes sensors, controllers and automation software to monitor various parameters during the filtration process, such as inlet water flow, filter drum speed, filter cake thickness, etc., and automatically start the backwash process as needed.

5. Shell:

The outer casing is used to protect internal components and prevent external contaminants from entering, while also supporting and fixing them. The housing is usually made of corrosion-resistant materials to suit the requirements of the wastewater treatment environment.

What are the application areas of drum filters in sewage treatment?

Rotary drum filters are widely used in sewage treatment plants due to their efficient solid-liquid separation capabilities and automated operation features. Its main application areas include: primary treatment, secondary treatment, sludge dewatering, and industrial wastewater treatment.

1. Primary processing:

In the primary treatment stage of sewage treatment plants, drum filters are used to remove large suspended particles and sediments in wastewater, reduce the load on subsequent treatment equipment, and improve the efficiency of the entire treatment system.

2. Secondary processing:

In the secondary treatment stage, the drum filter is used to further remove fine suspended solids and organic matter in the wastewater to ensure that the effluent water quality meets the discharge standards or reuse standards. The drum filter can be used in combination with biological treatment processes (such as activated sludge method, biofilm method) to enhance the solid-liquid separation effect.

3. Sludge dehydration:

Rotary drum filters can also be used for sludge dehydration to remove water from the sludge, increase the solid content of the sludge, reduce the volume of the sludge, and reduce the cost of subsequent sludge treatment and disposal.

4. Industrial wastewater treatment:

In industrial wastewater treatment, drum filters are widely used in printing and dyeing, papermaking, food processing, chemical and other industries to remove suspended solids, grease and other pollutants in wastewater, protect downstream treatment equipment, and improve the overall treatment effect.

What are the advantages of drum filters?

The application of drum filters in sewage treatment has several significant advantages: high-efficiency filtration, automated operation, energy conservation and environmental protection, small footprint, and strong adaptability.

1. High efficiency filtration:

The drum filter can continuously and efficiently remove suspended solids in wastewater. It has high filtration accuracy and large processing capacity, and is suitable for various sewage treatment needs.

2. Automated operation:

The drum filter is equipped with an automated control system, which can monitor the operating status in real time, automatically adjust the rotation speed and backwash frequency, realize unattended operation, and reduce operation and maintenance costs.

3. Energy saving and environmental protection:

The energy consumption of the drum filter is relatively low, and there is no need to add chemicals, which avoids secondary pollution and has good environmental performance.

4. Small footprint:

The rotary drum filter has a compact structure and a small footprint. It is suitable for sewage treatment plants with limited space and is easy to install and maintain.

5. Strong adaptability:

Rotary drum filters can handle different types and concentrations of wastewater. They have strong adaptability and a wide range of applications, and can meet various sewage treatment needs.

Conclusion about drum filters

As an efficient and automated solid-liquid separation equipment, the drum filter plays an important role in sewage treatment plants. Its advantages such as high-efficiency filtration, automated operation, energy saving and environmental protection make it an indispensable and important equipment in the field of sewage treatment. Understanding the definition, working principle, components and application of drum filters in sewage treatment will help to better select and use this advanced water treatment technology, improve sewage treatment effects, protect the environment, and achieve resource utilization. Efficient utilization.