How long is the service life of an industrial reverse osmosis filter?

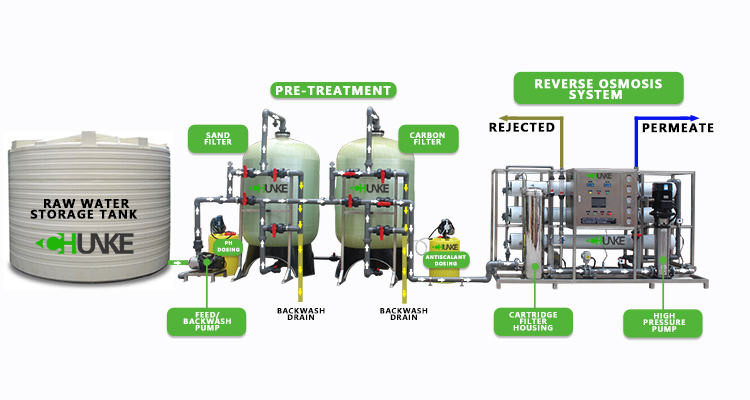

Industrial reverse osmosis filters are an important part of the water treatment system, and their service life directly affects the water treatment effect and the operation stability of the equipment. According to experience and practice, the service life of industrial reverse osmosis filters is generally 2 to 5 years, and the specific service life needs to take into account the life of each component.

Pre-filter and sediment filter

First of all, pre-filters and sediment filters are the first filtration equipment in industrial reverse osmosis systems, mainly used to remove large particle impurities and sediments in water. The service life of these filters is generally about 6 to 12 months, and they need to be replaced regularly to ensure the filtration effect.

Carbon filter

Secondly, carbon filters play a role in removing odors, colors and organic matter in industrial reverse osmosis systems, and their service life is generally between 6 and 12 months. When the carbon filter reaches a certain period of use, its adsorption capacity will weaken and needs to be replaced in time to maintain the filtration effect.

Reverse osmosis membrane

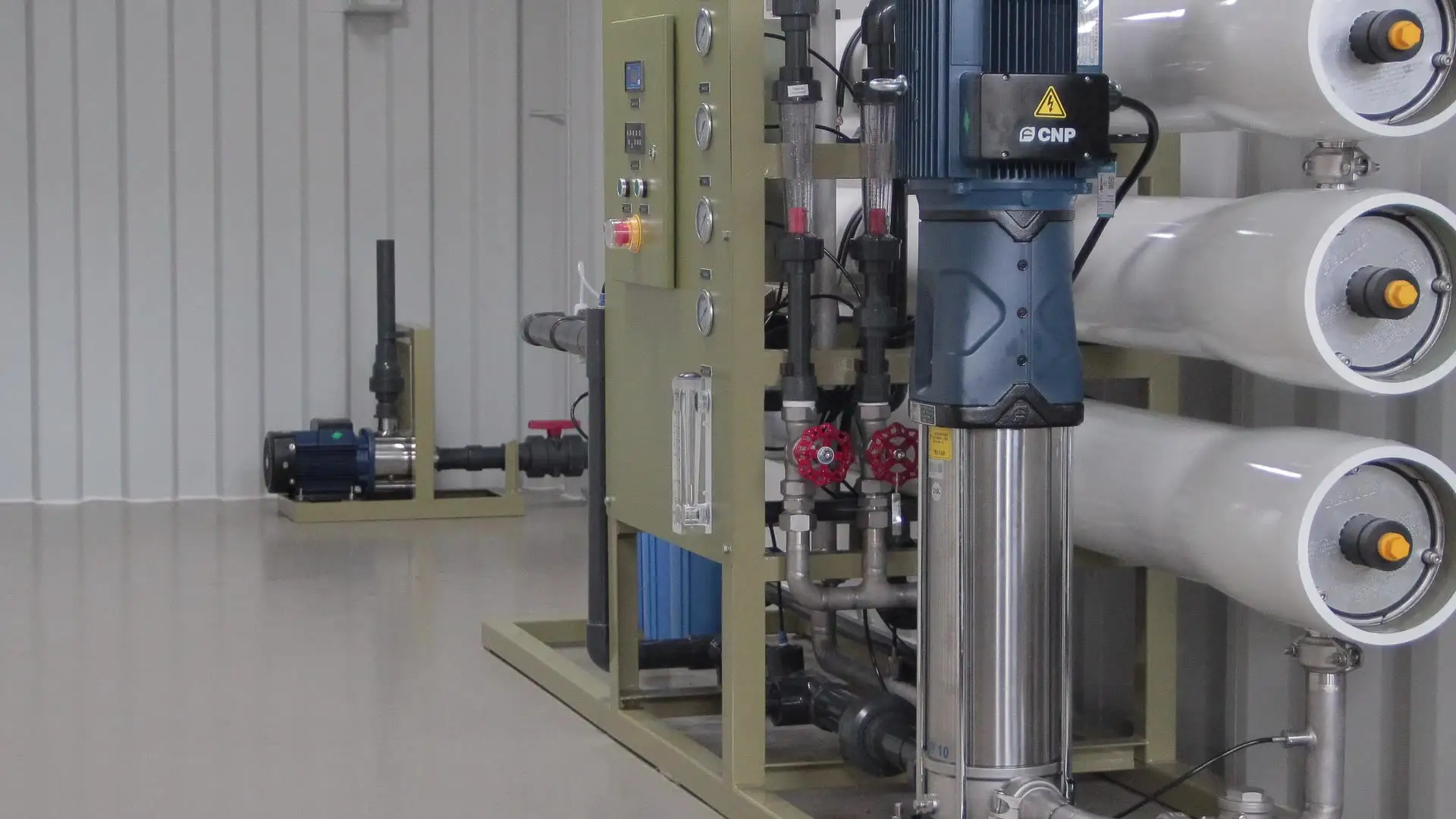

Finally, the reverse osmosis membrane is one of the most critical components in the industrial reverse osmosis system, and its service life is generally 2 to 5 years. The life of the reverse osmosis membrane is affected by many factors, including water quality, operating conditions, maintenance, etc. Regular cleaning and maintenance of reverse osmosis membranes can extend their service life and ensure the normal operation of the water treatment system.

How do industrial reverse osmosis filters affect industrial production?

The life and maintenance of industrial reverse osmosis filters directly affect the stability and efficiency of industrial production. Therefore, it is very important to understand its lifespan and maintenance. Industrial reverse osmosis filters can effectively remove impurities and harmful substances in water, ensuring the purity and stability of water quality required in industrial production, thereby ensuring the smooth progress of the production process. Regular maintenance and replacement of filters to extend the service life of the system can not only reduce maintenance costs, but also improve production efficiency and product quality, bringing more benefits to industrial production.

How to extend the service life of industrial reverse osmosis filters?

Regular maintenance

First of all, regular maintenance is the key to extending the service life of industrial reverse osmosis filters. Including cleaning the pre-filter and sediment filter, replacing the carbon filter and regularly checking the reverse osmosis membrane, etc., can effectively extend the service life of the filter.

Optimize operating conditions

Secondly, optimizing operating conditions is also an important measure to extend the life of industrial reverse osmosis filters. Controlling water quality and temperature, avoiding water quality fluctuations and impacts, and reasonably controlling pressure and flow can reduce the loss of the filter and extend its service life.

Timely replacement of aging parts

In addition, timely replacement of aging parts is also an effective way to extend the life of industrial reverse osmosis filters. When the pre-filter, carbon filter or reverse osmosis membrane reaches a certain use time, its filtration effect will decrease and needs to be replaced in time to ensure the water treatment effect.

What about the maintenance and cost of industrial reverse osmosis filters?

Maintenance costs

The maintenance costs of industrial reverse osmosis filters mainly include regular replacement of filter elements and membrane elements, cleaning and maintenance of equipment, testing and monitoring of water quality, etc. Although the maintenance cost is high, compared with the equipment operation stability and water treatment effect, the investment is very worthwhile.

Operating costs

In addition, the operating costs of industrial reverse osmosis filters also need to take into account energy consumption and labor maintenance costs. By optimizing operating conditions, improving equipment efficiency and regular maintenance, operating costs can be reduced and the economic benefits of equipment can be improved.

Industrial reverse osmosis filters are an important part of water treatment systems, and their service life is generally 2 to 5 years. Pre-filters, carbon filters, and reverse osmosis membranes are common filters found in industrial reverse osmosis systems and have varying service lives. To extend the service life of industrial reverse osmosis filters, regular maintenance, optimization of operating conditions and timely replacement of aging parts are required.

Although the maintenance cost is high, compared with the equipment operation stability and water treatment effect, the investment is very worthwhile. By reasonably controlling operating costs, the economic benefits of equipment can be improved and the normal operation of the water treatment system can be ensured.