Can seawater be filtered? What is the best seawater filter?

As the most abundant water resource on earth, seawater accounts for the vast majority of the world's water bodies. However, due to its large amount of impurities such as salt, microorganisms, organic matter, suspended particles, etc., direct use of seawater poses huge challenges in daily life and industrial production. With the increasing tension of global freshwater resources, seawater filtration and desalination technology has gradually become an important means to solve the problem of freshwater shortage.

So, can seawater be filtered? What is the best seawater filter? This article will explore these issues in depth.

What is seawater filtration?

Before answering the question "Can seawater be filtered?", we first need to clarify what "filtration" is. In the field of water treatment, filtration usually refers to the process of removing impurities such as suspended matter, dissolved matter, organic matter and microorganisms in water through some physical, chemical or biological methods. For seawater, due to its complex composition, the filtration process is relatively more complicated and strict.

1. Physical filtration: mainly relies on physical barriers such as filters or membranes to remove large particles such as particles, silt, microorganisms, etc. in seawater.

2. Chemical filtration: Remove dissolved substances in water, such as metal ions, organic compounds, etc., through chemical reactions or adsorption methods.

3. Biological filtration: Use microorganisms to degrade organic matter in water. Biological filters commonly used in sewage treatment are less used in seawater treatment.

Although the composition of seawater is complex, with the advancement of water treatment technology, seawater can completely reach the standard of fresh water through multi-stage filtration and treatment processes. In fact, seawater desalination technology has been widely used in many parts of the world and has become one of the effective means to deal with the freshwater crisis.

What are the main challenges of seawater filtration?

Although seawater can be filtered, seawater filtration faces greater challenges than the treatment of ordinary fresh water. Here are some of the main difficulties:

1. High salinity: The salinity of seawater is about 3.5%, and the main component is sodium chloride. High salinity makes it difficult to directly apply traditional water filtration technology, and special desalination technologies such as reverse osmosis and distillation must be used.

2. A wide variety of impurities: Seawater contains a variety of impurities, including suspended matter, microorganisms, organic matter, heavy metals, etc. The effective removal of these impurities requires the synergy of multiple filtration technologies.

3. High corrosiveness: The salt and other chemical components in seawater are highly corrosive and can easily damage filtration equipment and pipelines. Therefore, seawater filtration equipment usually needs to use corrosion-resistant materials to extend its service life.

4. High energy consumption: Due to the need to overcome high salinity and complex impurities, seawater filtration usually requires more energy and resources than freshwater treatment. Therefore, energy consumption is an important consideration for seawater filtration technology.

What are the commonly used seawater filtration technologies?

In practical applications, the filtration and treatment of seawater is usually not completed by a single technology, but by a combination of multiple technologies to achieve the expected water quality standards. The following are several commonly used seawater filtration technologies:

1. Mechanical filtration: Mechanical filtration is the first step in seawater treatment, mainly used to remove large particles in seawater, such as suspended matter, silt, seaweed, etc. Common mechanical filtration equipment includes sand filters, mesh filters, etc.

2. Microfiltration and ultrafiltration: After mechanical filtration, seawater usually needs to undergo microfiltration or ultrafiltration to further remove small particles, bacteria and some organic matter. The membranes used in microfiltration and ultrafiltration have smaller pores and can effectively intercept smaller particles.

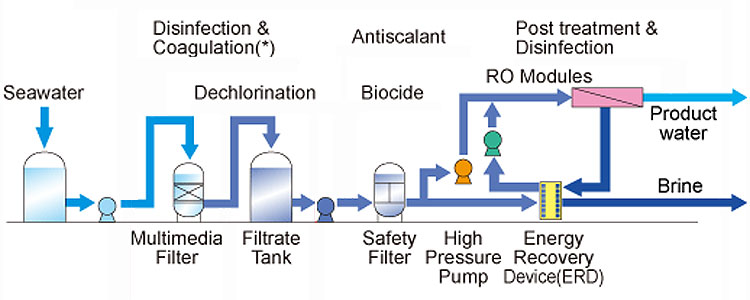

3. Reverse Osmosis (RO): Reverse osmosis technology is one of the most commonly used seawater desalination technologies. It uses the selective permeability of semipermeable membranes to separate water molecules from dissolved salts and other impurities in seawater under high pressure. Reverse osmosis systems are usually one of the core equipment in seawater desalination plants.

4. Electrodialysis: Electrodialysis is also a desalination technology that uses the action of an electric field to separate charged ions from water. Electrodialysis is usually used for low-salinity seawater or as a pretreatment step for reverse osmosis.

5. Distillation: Distillation is another classic seawater desalination method that removes salt by heating seawater and condensing steam. Due to its high energy consumption, distillation technology is usually used in special occasions or energy-rich areas.

6. Chemical treatment: In order to remove specific impurities in seawater, such as heavy metals and organic matter, chemical agents are often required for treatment. These chemicals can react with impurities to form easily removable precipitates or be adsorbed on the filter media.

What is the best seawater filter?

Choosing the best seawater filter depends on the specific usage scenario and water quality requirements. For example, the desalination needs of a home or small community are different from those of an industrial-grade desalination, and the type of filter required will also be different.

1. Home or small community use: For seawater treatment needs of a home or small community, an integrated reverse osmosis system is usually the best choice. This system is small in size, simple to operate, and can directly convert seawater into drinking water, which is suitable for home or small-scale users. In addition, choosing a filter with automatic backwashing function can reduce maintenance frequency and improve ease of use.

2. Industrial-grade application: For large-scale industrial applications, such as seawater desalination plants, chemical plants, etc., reverse osmosis systems are usually used as core technologies. In addition, pretreatment steps such as mechanical filtration, ultrafiltration, and chemical treatment are also essential to extend the service life of the reverse osmosis membrane and improve overall efficiency. Industrial-grade filters often require higher processing capacity and corrosion resistance to cope with long-term high-intensity operating environments.

3. Ships and offshore platforms: On ships and offshore platforms, compact reverse osmosis systems are often used due to space limitations and special environmental requirements. These systems need to have high salt resistance and corrosion resistance and be able to operate stably in harsh marine environments.

4. Specific purpose filters: For some special water treatment needs, such as removing specific pollutants from seawater or treating highly polluted seawater, customized filters may be required. These filters usually include specific adsorbent materials or dedicated chemicals to meet special water quality requirements.