What is the desalination price of a 2.5 m³/h seawater RO plant?

The global water shortage problem is becoming increasingly serious, and seawater desalination technology has become one of the important means to solve this problem. Seawater reverse osmosis (RO) technology is also one of the most mature and widely used seawater desalination technologies.

This article will explore the desalination cost of a seawater reverse osmosis plant with a capacity of 2.5 m³/h, analyze its influencing factors, and look forward to future development trends.

Overview of seawater reverse osmosis technology

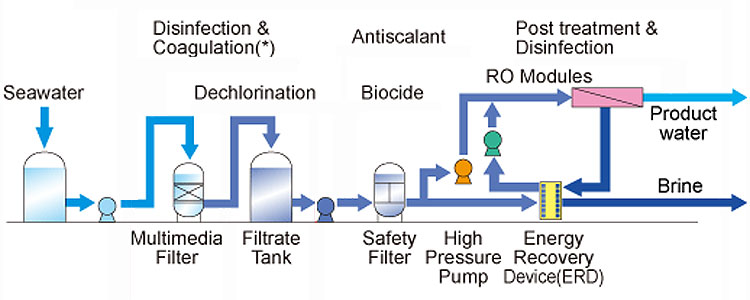

Seawater reverse osmosis technology is a desalination technology that removes salt and other impurities from seawater through a semipermeable membrane. The principle is to use high pressure to press seawater through a semipermeable membrane to prevent salt from passing through, thereby obtaining fresh water. Reverse osmosis technology has the advantages of low energy consumption, simple operation, and strong adaptability, and has become the mainstream technology for global seawater desalination.

Composition of a 2.5 m³/h seawater reverse osmosis plant

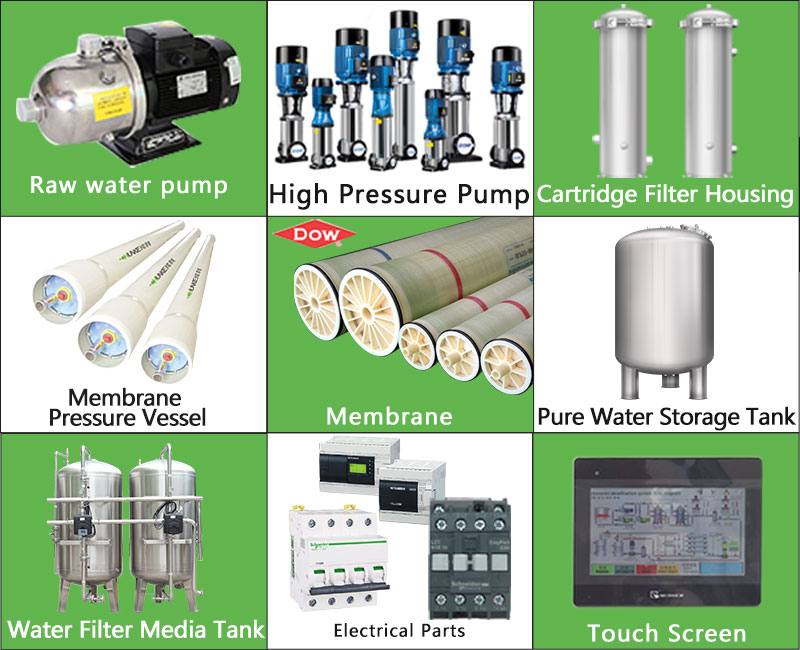

A standard 2.5 m³/h seawater reverse osmosis plant usually includes the following main parts:

1. Water inlet system: including seawater intake, pretreatment and other steps to ensure that the seawater quality entering the reverse osmosis membrane meets the requirements.

2. Reverse osmosis system: core part, including high-pressure pumps, reverse osmosis membrane components, etc.

3. Water production system: fresh water storage and delivery system.

4. Concentrated water discharge system: treatment and discharge of concentrated water.

What are the factors affecting the cost of seawater desalination?

The desalination cost of seawater reverse osmosis plants is affected by many factors, including equipment investment, energy consumption, maintenance costs, personnel costs, etc. The specific analysis is as follows:

1. Equipment investment

Equipment investment is one of the main costs of seawater reverse osmosis plants, including water intake equipment, pretreatment equipment, high-pressure pumps, reverse osmosis membrane components, control systems, etc. This part of the cost is usually one-time, but it has a greater impact on the overall cost.

2. Energy consumption

Energy consumption is the largest operating cost in the desalination process. The reverse osmosis process requires a high-pressure pump to pressurize seawater and pass it through a semi-permeable membrane, and energy consumption accounts for about 40% to 50% of the total cost. Therefore, it is crucial to choose efficient energy supply and energy-saving equipment.

3. Maintenance cost

The long-term operation of the reverse osmosis system requires regular maintenance, including replacement of reverse osmosis membranes, cleaning of pretreatment equipment, and maintenance of high-pressure pumps. This part of the cost is a long-term expenditure that cannot be ignored.

4. Personnel costs

The operation of the desalination plant requires professional technicians to operate and maintain it, and staff wages and training costs are also important components of the cost.

5. Other costs

Including concentrated water treatment and discharge costs, chemical agent costs, water quality testing costs, etc. These costs may vary depending on specific operating conditions and local regulations.

What is the desalination price of a 2.5 m³/h seawater reverse osmosis plant?

In order to more intuitively understand the desalination cost of a 2.5 m³/h seawater reverse osmosis plant, we will analyze it through a specific case.

Case: 2.5 m³/h seawater reverse osmosis plant in a coastal city in China

1. Equipment investment: The total investment is about US$300,000, including water intake equipment, pretreatment equipment, high-pressure pumps, reverse osmosis membrane components and control systems.

2. Energy consumption: The average power consumption is 4 kWh/m³. Based on the electricity price of $0.15/kWh, the hourly energy consumption cost is 2.5 m³/h × 4 kWh/m³ × $0.15/kWh = $1.5.

3. Maintenance cost: The annual maintenance cost is about $14,000, including reverse osmosis membrane replacement, equipment cleaning and daily maintenance.

4. Personnel cost: 3 professional technicians are equipped, with a total annual salary of about $150,000.

5. Other costs: The annual concentrated water treatment and discharge costs, chemical costs, water quality testing costs, etc. are about $7,000.

Based on the above data, the total annual cost of the seawater reverse osmosis plant can be calculated:

● The equipment investment is calculated based on 10 years of depreciation, and the annual depreciation cost is $30,000.

● Total annual cost = equipment depreciation cost + energy consumption cost + maintenance cost + personnel cost + other costs

● Total annual cost = $30,000 + $1.5/hour × 24 hours/day × 365 days/year + $14,000 + $150,000 + $7,000

● Total annual cost = $30,000 + $13,140 + $14,000 + $150,000 + $7,000 = $214,140

● The water output is 2.5 m³/h, running 24 hours a day, the annual water output is: Annual water output = 2.5 m³/h × 24 hours/day × 365 days/year = 21,900 m³

● The cost per cubic meter of fresh water is: Fresh water cost = Total annual cost / Annual water output Fresh water cost = $214,140/ 21,900 m³ ≈ 9.78 USD/m³

Conclusion

The 2.5 m³/h seawater reverse osmosis plant plays an important role in providing high-quality fresh water, but its operating cost is relatively high. By optimizing equipment, improving energy efficiency, and innovating membrane technology, the desalination cost can be effectively reduced and the popularization and application of seawater reverse osmosis technology can be promoted.