What is the best water filter for filtering brine?

Brine, also known as concentrated water or high-salinity water, is water that contains high concentrations of salt and other dissolved substances. This water is produced in many industrial and environmental processes, especially in desalination, chemical processing and mining processes. Due to the high salt and impurity content in brine, handling and filtering brine is a technical challenge, and choosing the right water filter is crucial.

So, what is the best water filter for filtering brine? What factors need to be considered in the selection process? This article will explore in depth.

What are the characteristics of brine and the difficulties in handling it?

Before discussing the best water filter, it is necessary to first understand the characteristics of brine and the difficulties in handling it. The high salt content, high mineral content, and possible heavy metals, chemicals and suspended particles in brine make it more challenging to handle than ordinary water.

The salinity in brine can be as high as tens of thousands or even hundreds of thousands of ppm (parts per million). This high salinity is not only corrosive to the filter media, but can also cause crystallization and render the filter ineffective. Brine may contain a large amount of suspended particles, microorganisms, organic matter and heavy metals, etc. These impurities can hinder the filtration process and easily cause clogging of the filter membrane or filter element. Concentrate water may also contain a variety of chemical components, such as calcium, magnesium, iron, manganese, etc. These components may react with the materials in the water filter at high concentrations, causing aging or damage to the materials.

What are the common methods for concentrating water?

Filtering concentrating water involves a variety of technologies and equipment, each of which has its own unique advantages and limitations. Here are some common methods for concentrating water:

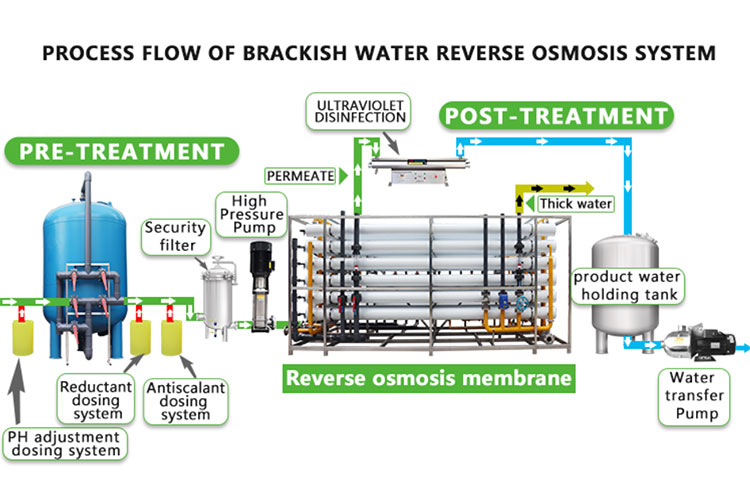

Reverse Osmosis (RO)

Reverse osmosis is a technology that removes impurities from water through a semipermeable membrane, commonly used in freshwater and seawater desalination. RO membranes are able to filter out most of the salt and impurities in water. However, due to the high salinity and impurity content of the concentrate, the reverse osmosis membrane is prone to scaling, clogging and shortened membrane life when filtering the concentrate. Therefore, when treating concentrate, the reverse osmosis system needs to be combined with a pre-treatment system, such as ultrafiltration or microfiltration, to extend the life of the membrane.

Electrodialysis (ED)

Electrodialysis is a technology that separates ions in water through an electric field. It is often used to treat water with high salt content. It can effectively remove salt from brine and has a strong ability to treat suspended particles and organic matter. However, electrodialysis systems have high requirements for operating conditions and high maintenance costs, and are not suitable for large-scale brine treatment.

Nanofiltration (NF)

Nanofiltration is between reverse osmosis and ultrafiltration. It can remove organic matter with small molecular weight, divalent ions and some salts. The pore size of the nanofiltration membrane is large, so it is not easy to clog when treating brine, and it can effectively reduce the hardness components such as calcium and magnesium in brine. However, since its removal rate is not as good as reverse osmosis, nanofiltration systems are usually used for partial treatment or pretreatment of brine.

Evaporation crystallization method

Evaporation crystallization is a method of evaporating water by heating and crystallizing the remaining solid solute. This method is usually used to treat extremely concentrated brine. It can remove almost all water by evaporation, leaving only solid salts. This method has high energy consumption and complex equipment, but it is very effective in treating high-concentration brine that is difficult to treat by other methods.

What is the best water filter for filtering brine?

Among the many filtration methods, choosing the best type of water filter requires considering the specific composition, concentration and treatment scale of the brine. The following water filters perform well in treating brine:

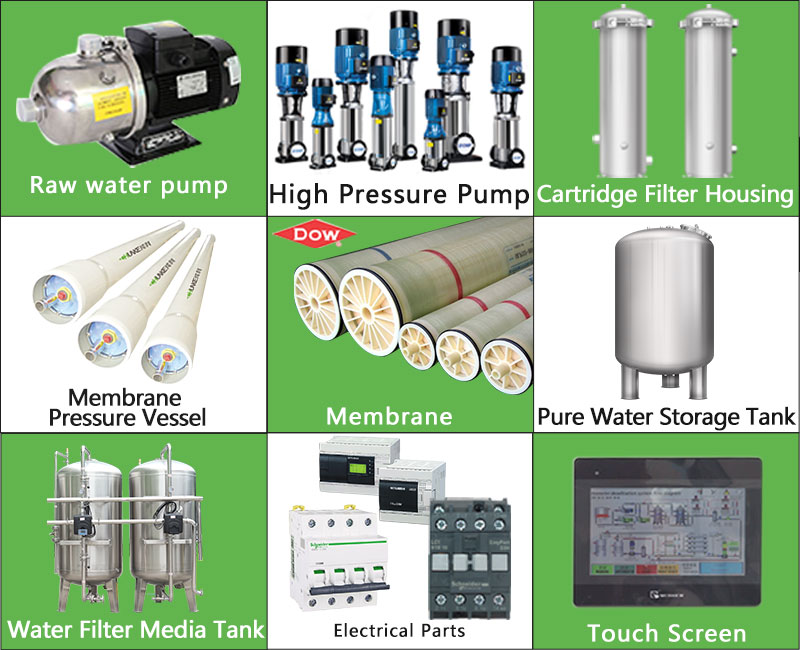

The composite membrane reverse osmosis system uses a multi-layer membrane structure to maintain high filtration efficiency when treating high-salinity water. These membranes are usually made of materials such as polyamide (PA) and have good salt and chemical resistance. The composite membrane reverse osmosis system can effectively remove most of the salt and impurities in the brine and is suitable for industrial-grade brine treatment. However, good pretreatment equipment is required before the system to reduce membrane fouling and scaling problems.

The ceramic filter element system has high mechanical strength and chemical resistance and can work for a long time in high temperature and high salinity environments. The microporous structure of the ceramic filter element can effectively block suspended particles and large molecular organic matter while allowing water molecules and small ions to pass through. For brine containing a large amount of suspended matter or requiring high temperature treatment, the ceramic filter element system is an ideal choice.

The multi-stage nanofiltration system combines the advantages of nanofiltration membranes and other membranes to gradually remove impurities from brine through step-by-step filtration. The system can effectively reduce the hardness of brine, reduce salinity, and remove some organic matter and heavy metals. The multi-layer filtration design of the multi-stage nanofiltration system makes it perform well in treating complex brine, and maintenance is relatively simple.

Membrane distillation is a water treatment method that combines membrane separation and evaporation technology to achieve efficient evaporation at lower temperatures. The membrane distillation system is suitable for treating water with high salinity and high mineral concentration, especially when recovering the pure water part of the water. Its disadvantages are high system energy consumption and high equipment cost, but it is still an effective choice when treating extreme brine.

How to choose a suitable brine filter?

When choosing a suitable brine filter, it is necessary to focus on the composition and concentration of brine. Different brine compositions are crucial to the selection of filters. For example, brine with high salt content may require a more corrosion-resistant filter membrane, while brine with a large amount of suspended matter requires a more efficient mechanical filter.

Secondly, the scale of treatment directly affects the type and specification of the filter. Small-scale brine treatment may use a single filter, while large-scale industrial treatment requires a multi-stage filtration system or a composite system. In addition, the cost and maintenance cost of brine treatment equipment are also important considerations when choosing. Although some high-efficiency filtration systems have a higher initial cost, they may be more economical in long-term operation.

Finally, the environmental conditions of brine treatment (such as temperature, pressure, and chemical composition) will affect the choice of water filter. For example, in a high-temperature environment, a ceramic filter element or a membrane distillation system may be more suitable. Wastewater and solid residues are often produced after brine treatment. How to effectively treat these wastewaters and residues, and how to maximize the recycling of water resources, are also factors that need to be considered when selecting a water filter.