What is biofilm filtration media for wastewater treatment?

Wastewater treatment is one of the important links in the field of modern environmental protection, and biofilm technology, as an efficient and environmentally friendly treatment method, plays an irreplaceable role in wastewater purification. Biofilm filtration media is the core component of this technology, providing a key carrier for the growth of biofilm and the treatment of wastewater. So, what exactly is biofilm filtration media for wastewater treatment? What specific role does biofilm play in wastewater treatment? This article will discuss in depth from the perspectives of concepts, principles and uses.

What is biofilm filtration media for wastewater treatment?

Biological Filtration Media for Wastewater Treatment is a material used to support the formation and maintenance of biofilms. Its function is to provide an ideal physical carrier for the growth of microorganisms. Biofilms are essentially a community of microorganisms attached to a solid surface. They can use organic matter in wastewater as nutrients and decompose or convert pollutants into harmless substances through metabolic processes.

Physical properties of media

Biofilm filter media are usually made of plastic, ceramic or other polymer materials, which have the following characteristics:

● High specific surface area: Provides sufficient surface space for microorganisms to attach and grow.

● Good water permeability: Ensures that wastewater can flow evenly through the surface of the media, optimizing the decomposition efficiency of pollutants.

● Corrosion resistance and stability: Not easy to degrade under long-term contact with wastewater and microbial metabolites.

● Lightweight structure: Easy to install and maintain, and suitable for a variety of wastewater treatment systems.

What are the common types of biofilm filter media?

Depending on the use and form, biofilm filter media can be divided into several types:

● Fixed media: Such as honeycomb ceramics, plastic plates and mesh structures. This type of media is fixed in the treatment equipment and is suitable for processes such as packed towers and trickling filters.

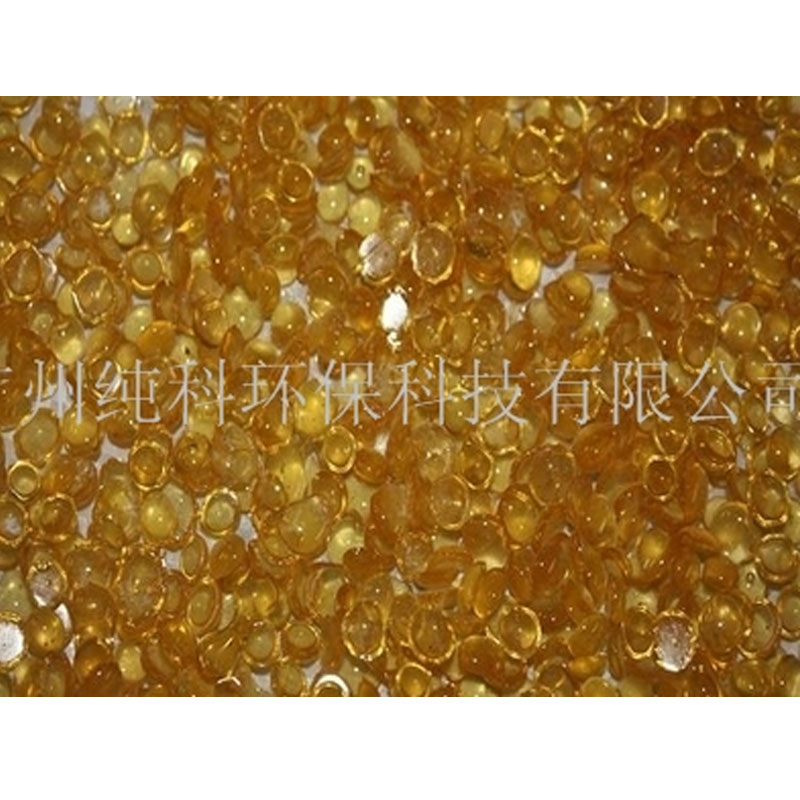

● Fluidized bed media: Such as spherical, granular or flaky plastics. This type of media can move with the water flow and is suitable for high-efficiency treatment systems such as fluidized bed reactors.

● Suspended media: Such as lightweight plastic particles or specially designed hollow fibers, suitable for the improvement or additional treatment of activated sludge systems.

Functions of biofilm media

The biofilm filtration media not only provides space for microorganisms to attach, but also promotes the efficient progress of the wastewater treatment process by optimizing the water flow path and increasing the oxygen supply. The design and selection of the media directly affect the thickness, density and diversity of the biofilm and the microbial population.

What is the role of biofilm in wastewater treatment?

The core role of biofilm in wastewater treatment is to degrade pollutants, including organic matter, nitrogen, phosphorus and some difficult-to-degrade substances through microbial metabolism. As a micro-ecosystem, it has the following key functions in the wastewater purification process:

Removal of organic pollutants

The heterotrophic microorganisms in the biofilm can decompose organic matter (such as carbohydrates, proteins and fats) in the wastewater and convert them into carbon dioxide (CO₂), water (H₂O) and other inorganic substances. This process not only reduces the chemical oxygen demand (COD) of the wastewater, but also significantly reduces the biochemical oxygen demand (BOD).

● Decomposition mechanism: Microorganisms decompose complex macromolecular organic matter into small molecular compounds by secreting enzymes, and then further oxidize them completely through metabolic pathways.

● Removal efficiency: Due to the high specific surface area and high microbial density of the medium, biofilm technology can usually achieve an organic pollutant removal rate of more than 80%.

Nitrogen removal (nitrification and denitrification)

Biofilm technology also has significant advantages in treating nitrogen-containing wastewater. Through the two stages of nitrification and denitrification, ammonia nitrogen (NH₄⁺) in the wastewater is eventually converted into nitrogen gas (N₂) and discharged into the atmosphere.

● Nitrification: Under aerobic conditions, ammonia nitrogen is oxidized to nitrate (NO₃⁻) by nitrifying bacteria (such as Nitrosomonas and Nitrosomonas).

● Denitrification: Under anaerobic conditions, denitrifying bacteria reduce nitrate to nitrogen gas.

● Co-treatment: The layered structure of the biofilm (the outer layer is the aerobic zone and the inner layer is the anaerobic zone) can achieve nitrification and denitrification at the same time, greatly improving the denitrification efficiency.

Phosphorus removal

In some wastewater treatment systems, microorganisms (especially polyphosphate bacteria) in biofilms can reduce the phosphorus content in wastewater by absorbing and storing phosphates in wastewater. This biological phosphorus removal technology is usually used in combination with chemical precipitation to achieve better results.

Removal of refractory substances

The diverse microbial communities in biofilm systems can degrade certain refractory organic matter, such as benzene, phenolic compounds and polycyclic aromatic hydrocarbons, through synergistic metabolism. These microorganisms can secrete special enzymes and oxidants under specific conditions to effectively decompose stubborn pollutants in wastewater.

What are the application scenarios of biofilm filter media?

Due to its efficient pollutant removal ability and low operating cost, biofilm filter media are widely used in various wastewater treatment scenarios, including but not limited to the following fields:

Urban sewage treatment

Biofilm media are often used in trickling filters, contact oxidation tanks and other processes in urban sewage treatment plants to help remove organic matter and nitrogen and phosphorus pollutants in sewage. Such facilities usually require the media to provide a stable microbial attachment environment to meet high-load treatment needs.

Industrial wastewater treatment

Industrial wastewater may contain a large amount of organic matter and refractory substances. Biofilm filtration media can improve treatment efficiency by increasing the diversity and concentration of microbial populations. For example, in wastewater treatment in the pharmaceutical, food processing and chemical industries, biofilm media are often used as the main treatment method.

Aquaculture wastewater

In aquaculture, biofilm media are used to remove excessive ammonia nitrogen and organic matter in the water body, keep the water clean and the aquaculture environment stable. Fluidized bed biofilm media are often used in wastewater purification systems in large farms due to their high treatment capacity.

Rural domestic sewage treatment

In rural areas, biofilm technology has become an important way to treat domestic sewage due to its simple equipment and easy maintenance. The ecological sewage treatment system using biofilm media can effectively remove pollutants while being both economical and environmentally friendly.

Maintenance and precautions of biofilm filtration media

Biomembrane filtration media need to be reasonably maintained in actual operation to ensure its long-term and efficient operation. Here are a few key considerations:

● Regular cleaning: Since suspended matter in wastewater may adhere to the surface of the medium, affecting the smooth flow of water and the growth of biofilm, the medium should be cleaned regularly to avoid blockage.

● Control the quality of influent water: High concentrations of toxic substances or large suspended matter may affect the stability of the biofilm, and a pretreatment unit should be set at the inlet end.

● Maintain an appropriate water flow rate: Too high or too low a water flow rate will affect the formation and metabolic efficiency of the biofilm, so the water flow parameters need to be adjusted through equipment.