How to deal with concrete mud? What equipment is needed?

Concrete mud is a byproduct produced during the concrete construction process, usually containing cement, fine sand, dust and other components. This mud is handled arbitrarily at the construction site, which will not only pollute the environment, but also may have adverse effects on human health. Therefore, the correct treatment of concrete mud is not only a requirement for environmental protection, but also a specification that must be followed in construction.

This article will discuss in detail the reasons, specific methods and equipment required for concrete mud treatment.

Why should concrete mud be treated with water?

Concrete mud is inevitably produced during construction, but if it is not treated with water, it may bring a series of problems.

Environmental pollution

Concrete mud contains high concentrations of alkaline substances and fine particles, and direct discharge will pollute the soil and water. Once the alkaline components in the mud enter the soil, they will change the pH value of the soil, destroy the soil structure, and affect plant growth; after flowing into rivers or groundwater, it may cause harm to aquatic organisms and affect water quality.

Legal and regulatory requirements

With the increasingly stringent environmental protection laws and regulations, many countries and regions have clear regulations on wastewater treatment at construction sites. Discharging untreated concrete slurry may not only result in fines for the construction party, but may also cause the project to be suspended and even have a negative impact on the company's reputation.

Safety hazards

The accumulation of concrete slurry on the construction site may pose a slip hazard, especially in slippery conditions. This not only poses a threat to workers, but may also affect the construction progress.

Resource waste

Concrete slurry contains a large amount of cement and fine sand, which are all building materials. If it can be effectively treated and recycled, it can reduce material waste and construction costs.

How to treat concrete slurry with water?

There are many ways to treat concrete slurry with water, and the specific choice should be determined based on the amount, composition, and actual conditions of the slurry. The following are several common water treatment methods.

Sedimentation method

Sedimentation method is one of the simplest and most commonly used methods for treating concrete slurry. By setting up a sedimentation tank and introducing the slurry into it, after a period of standing, the solid particles in the slurry will gradually sink to form sediment, and the upper layer of clean water can be discharged or reused.

Advantages of sedimentation method:

● Simple operation and low cost.

● The clean water after sedimentation can be reused in construction to reduce water waste.

Disadvantages of sedimentation method:

● Large floor space and long sedimentation time.

● Relatively low treatment efficiency, unable to remove all fine particles.

Filtration method

The filtration method separates solid particles from concrete slurry by using a filter or filter. This method is suitable for slurry treatment with larger particles and can effectively reduce sedimentation time.

Advantages of filtration method:

● Fast processing speed and high efficiency.

● Small equipment footprint.

Disadvantages of filtration method:

● High maintenance requirements for equipment, and filters are prone to clogging.

● The filtration effect is greatly affected by slurry concentration.

Centrifugal separation method

The centrifugal separation method uses centrifugal force to separate solid particles from liquid in concrete slurry. This method is suitable for large-scale slurry treatment, especially when the slurry concentration is high.

Advantages of centrifugal separation method:

● High separation efficiency, suitable for various slurry concentrations.

● Both the separated solid particles and clean water can be reused.

Disadvantages of centrifugal separation method:

● High equipment cost and complex operation.

● The technical requirements for operators are high.

Chemical treatment method

The chemical treatment method is to add chemical agents to aggregate the solid particles in the concrete slurry into larger agglomerates, thereby accelerating their sedimentation or filtration. This method is suitable for the treatment of slurry containing fine particles or difficult to precipitate.

Advantages of chemical treatment method:

● It can treat particles with very small particle size with significant results.

● Fast processing speed and high efficiency.

Disadvantages of chemical treatment method:

● It is necessary to purchase and store chemical agents, which is costly.

● The treated wastewater may require further treatment to prevent chemical pollution.

Reuse method

The reuse method refers to the reuse of water and solid particles in the treated concrete slurry separately. For example, clean water can be reused for concrete mixing or other construction processes, while solid particles can be used as fillers or raw materials for other building materials. This method not only reduces waste emissions, but also improves resource utilization.

Advantages of reuse method:

● Effectively reduce resource waste, environmentally friendly and economical.

● It can reduce the demand for fresh water resources and save costs.

Disadvantages of the reuse method:

● A complete reuse system needs to be established, and the initial investment is large.

● The treatment process is complicated and requires multiple treatments and tests.

What equipment is needed for water treatment of concrete slurry?

The equipment required for water treatment of concrete slurry depends on the treatment method adopted. The following are commonly used equipment and their functions.

Sedimentation tank

The sedimentation tank is an indispensable equipment for treating slurry by sedimentation. Generally speaking, the design of the sedimentation tank should take into account the flow rate of the slurry, the sedimentation time and the actual conditions on site. The sedimentation tank is usually made of concrete or steel, and baffles may be set inside to increase the sedimentation effect.

Function of the sedimentation tank:

● The solid particles in the slurry are settled to the bottom of the tank, and the clean water on the upper layer can be discharged or reused.

● It can be used for preliminary treatment of large-scale slurry.

Filter

The filter is used to treat slurry by filtration, and is usually installed in the path of the slurry flow to intercept the solid particles in it. The filter element or filter screen of the filter needs to be cleaned or replaced regularly to ensure the treatment effect.

Function of filter:

● Separate solid particles in mud, and clean water can be directly discharged or reused.

● Suitable for processing mud with larger particles.

Centrifuge

The centrifuge is the core equipment of the centrifugal separation method. It separates solid particles from liquid in mud through the centrifugal force generated by high-speed rotation. Centrifuges usually require large energy consumption and certain operating techniques.

Function of centrifuge:

● Quickly separate solids and liquids in mud, suitable for high-concentration mud treatment.

● The separated solid particles and clean water can be reused separately.

Chemical dosing equipment

In chemical treatment methods, chemical dosing equipment is used to accurately control the amount of chemical agents added to ensure the best treatment effect. The equipment usually includes a chemical storage tank, a dosing pump and a related control system.

Function of chemical dosing equipment:

● Accurately add chemical agents to the mud to cause the particles to clump together for subsequent treatment.

● Ensure the stability and efficiency of the treatment process.

Pump and piping system

No matter what water treatment method is used, pumps and piping systems are essential equipment. Pumps are used to transport mud to the processing equipment, while the piping system is responsible for the flow and distribution of mud. Appropriate pump and piping system design can improve processing efficiency and reduce equipment wear and blockage.

Pump and piping system functions:

● Ensure smooth flow of mud during processing.

● Improve the efficiency and reliability of the overall processing system.

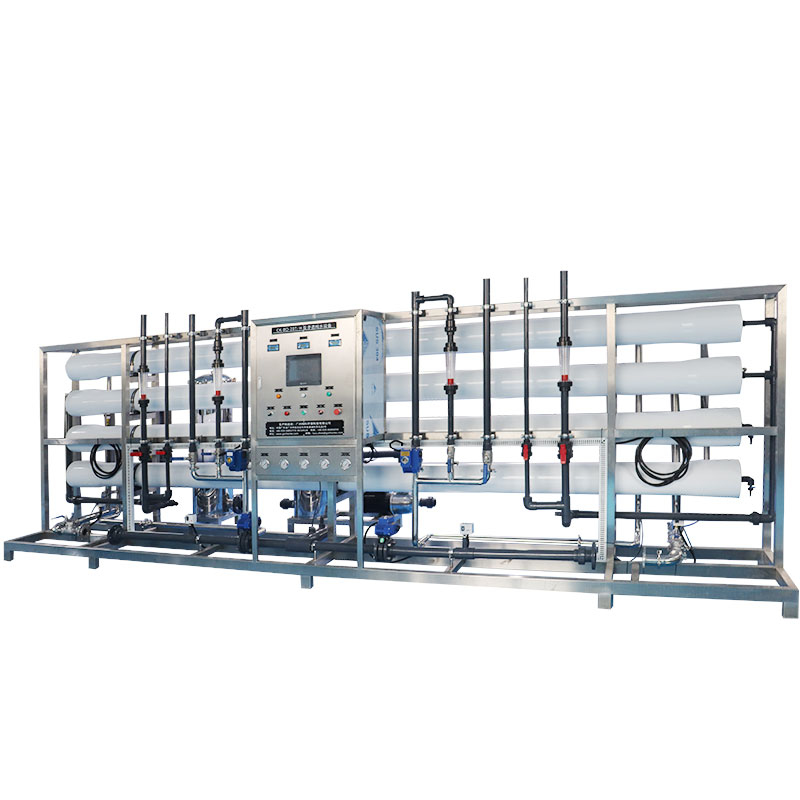

CHUNKE is a reverse osmosis company. Our product range includes industrial and commercial reverse osmosis water treatment systems, brackish water desalination plants, seawater desalination machines, river water filtration systems, groundwater purification equipment, well water filtration systems, well water purification systems, electrodeionization EDI water treatment systems, ion exchange water treatment systems, ultrafiltration UF membrane systems, etc. If you have any needs, please contact us!