Industrial Reverse Osmosis Water Purification Systems

Industrial Reverse Osmosis Water Purification Systems

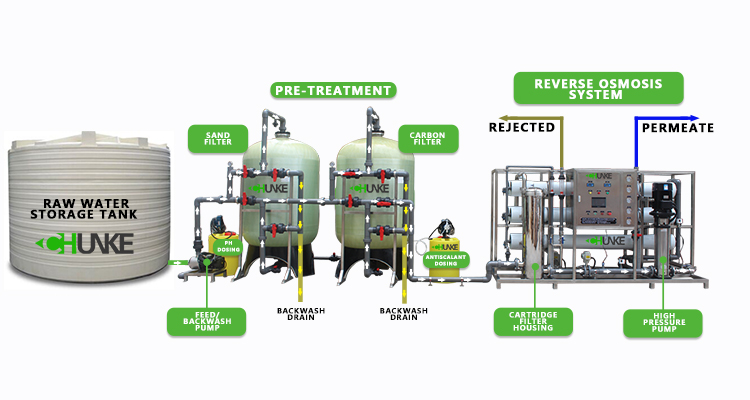

Industrial Reverse Osmosis Water Purification Systems is used to purify water. This system consists of booster pump, FRP pretreatment tanks (sand filter, activated carbon filter), SS304 cartridge filter housing, chemical dosing systems, high pressure pump, FRP membrane pressure vessel, 8040 membranes, control panel and touch screen control.

Material and parts brand can be changes as regards to raw water quality and customer demand.

From touch screen panel, you can see all system flow diagram and automatic or manual control the system.

Membranes do not allow small particles, virus, bacteria to pass permeate water as a result your water becomes very clean and safe.

INDUSTRIAL REVERSE OSMOSIS WATER PURIFICATION SYSTEMS

![]()

Industrial Water Purification System Capacity range between 38m3/day to 7500m3/day. If you need smaller than this capacity please see our commercial water treatment systems.

All industrial reverse osmosis water treatment systems are started from booster pump, it feeds raw water to pretreatment tanks. Depends on capacity pretreatment tank size and numbers can be changed. Also depend on raw water source and TDS (Total Dissolved Solid) material can be changed. In Chunke if water source is Tap or low TDS fresh water, we can use FRP, Stainless Steel 304 or 316. If salt content and TDS high, because of the corrosion, we are using FRP or Carbon Steel material for pretreatment tanks. Pretreatment consists of Sand Media Filter Tank, Activated Carbon Filter Media Tank and Softener Tank which has ion exchange resin inside, they are very important for reverse osmosis water filtration.

Pretreatment is used to remove large number of suspended solids, iron, turbidity, unwanted color, unpleasant taste, chlorine, sediment, organic contaminants, odors. In pretreatment we can control the flow manual or automatic for industrial water purification.

After pretreatment water goes to cartridge filter housing, we call it as security filter, most of industrial water treatment system application we are using stainless steel 304 or 316 material, but if water is very salty like brackish or seawater, we can use carbon steel, FRP or PVC Plastic Cartridge Filter Housing or Bag Filter Housing. There is 1µm or 5 µm PP filter in cartridge filter housing at industrial water treatment system.

After cartridge filter housing, water goes to membrane pressure vessel with High Pressure Pump, you have brand option for High Pressure Pump and it allows you to adjust your budget. Membrane housing shell inside depends on capacity we have 4040 or 8040 Membranes. Most of our project we are using DOW Filmtec, Toray, Vontron, Hydranautics, LG brand as ro membrane.

Membranes, in industrial reverse osmosis water purification systems, are most important part. They block matters size bigger than 0.001µm and molecular weight up to 150-250Dalton. It consists of impurities, particles, sugars, proteins, bacteria, dyes, organic and inorganic solids.

Also, reverse osmosis water filtration system can have chemical dosing at pretreatment or post treatment, like antiscaling (antiscalant), antifouling, pH adjustment, Sterilization Disinfection chemicals.

In Chunke when we check customer water analysis report, sometimes because of scaling and fouling problems, we can use CIP (Clean In Place) System, it wash membrane in membrane housing and make membrane clean so on membrane life longer.

Parts for Industrial Reverse Osmosis Water Filtration Plant

Electrical Power of industrial water treatment system

For industrial water purification plant needs 220-380V/50Hz/60Hz. For bigger capacity, because of high pressure pump, it needs 380V 50/60Hz. As regards to your reverse osmosis water filtration machine design, we will check your electrical supply and decide fix power to you.

MODELS

Model Number | Permeate Flow Rate | Membranes | |

Liter/Hour | Size | Quantity | |

CK-RO-2000L | 2000 | 4040 | 8 |

CK-RO-3000L | 3000 | 8040 | 3 |

CK-RO-4000L | 4000 | 8040 | 4 |

CK-RO-5000L | 5000 | 8040 | 5 |

CK-RO-6000L | 6000 | 8040 | 5-6 |

CK-RO-8000L | 8000 | 8040 | 8 |

CK-RO-10000L | 10000 | 8040 | 10 |

CK-RO-15000L | 15000 | 8040 | 14-15 |

CK-RO-20000L | 20000 | 8040 | 20 |

CK-RO-30000L | 30000 | 8040 | 30 |

CK-RO-45000L | 45000 | 8040 | 45 |

CK-RO-100000L | 100000 | 8040 | 100 |

CK-RO-200000L | 200000 | 8040 | 200 |

Before Buying Industrial Water Purification System, you should know:

1. Pure Water Production Capacity (L/day, L/Hour, GPD).

2. Feed Water TDS and Raw Water Analysis Report (prevent fouling and scalling problem)

3. Iron and Manganese must be removed before raw water enter reverse osmosis water filtration membrane

4. TSS (Total Suspended Solid) must remove before industrial water purification system’s membrane.

5. SDI (Silt Density Index) must be less than 3

6. Must be sure your water source does not have oil and grease

7. Chlorine must be removed before industrial water treatment system

8. Available electrical power voltage and phase

9. Layout of place for industrial RO reverse osmosis system

Features of Industrial Water Purification Systems

Standard Futers | Available Options |

Programmable PLC Control | Automatic Flush |

Motor Starter | Ozone Generator |

Raw Water Feeding/Booster Pump | UV Sterilizer |

Stainless Steel Cartridge Filter Housing | Chemical Dosing |

FRP Membrane Housing | pH control monitor |

Mitsubishi Processor Control | ORP Control monitor |

Low Pressure Switch | Remote Control |

High Pressure Switch | Pretreatment System |

Liquid filled pressure gauge | Post Deionization Unit |

Stainless Steel 304 Frame | CIP Membrane cleaning system |

Permeate Conductivity Monitor | Touch Screen Control |

Raw Water Conductivity Monitor | Tank Level Switch |

Membranes | Customer Logo |

Control Valves | |

Stainless Steel/UPVC Piping |

Operation Specification for Industrial Water Treatment System

Feed Water TDS > 1000ppm | Hardness over 18ppm needs antiscalant dosing | Turbidity must be removed |

Max. Feed Water Temp: 42°C | Operate at higher TDS results lower recovery | H2S must be removed |

pH tolerance: 3-11 | Max. iron content: 0.05ppm | / |

Feed Water Pressure: 1.5 to 6 bar | Max. Silica tolerance: 60ppm | / |