Does the laboratory of a drinking water plant need water treatment equipment?

In a drinking water plant, water quality safety is always the top priority. One of the key links to ensure that water quality meets the standards is the laboratory of the drinking water plant. The laboratory is not only responsible for testing the various indicators of the water leaving the factory, but also for monitoring each link in the water treatment process to ensure that every drop of water meets the safety standards.

However, in order to ensure the accuracy and reliability of the test, the laboratory itself also needs to use special water treatment equipment. So, does the laboratory of a drinking water plant need to be equipped with water treatment equipment? What are these specific equipment? This article will explore these issues in detail.

Why does the laboratory of a drinking water plant need water treatment equipment?

The main responsibility of the laboratory of a drinking water plant is to ensure that the water quality meets the national and local drinking water standards through various physical, chemical and biological testing methods. In order to achieve this goal, the laboratory often needs to use highly pure water when testing samples. For example, in chemical analysis, if the water used contains impurities, these impurities may interfere with the test results and cause inaccurate data. Therefore, the water quality used in the laboratory must be much higher than the standard of ordinary drinking water, usually reaching a special grade of laboratory water, such as ultrapure water or deionized water.

In addition, water treatment equipment not only provides high-purity water for laboratories, but can also be used for sample pretreatment, cleaning of experimental equipment and other links. Whether it is for trace element analysis, drug dissolution, or providing water for culture medium preparation, laboratory water treatment equipment plays a key role.

What types of water treatment equipment are commonly used in laboratories?

According to the different testing needs of the laboratory, drinking water plant laboratories usually need to use a variety of water treatment equipment. The following are some common laboratory water treatment equipment and their functions:

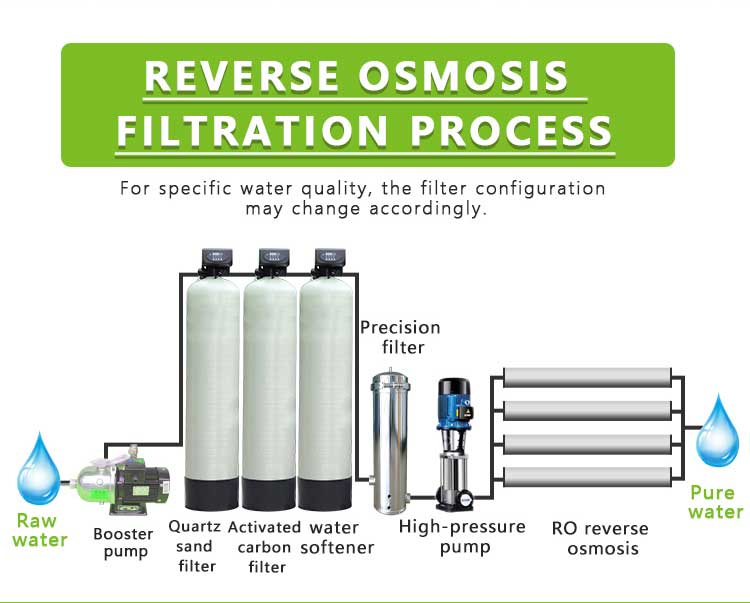

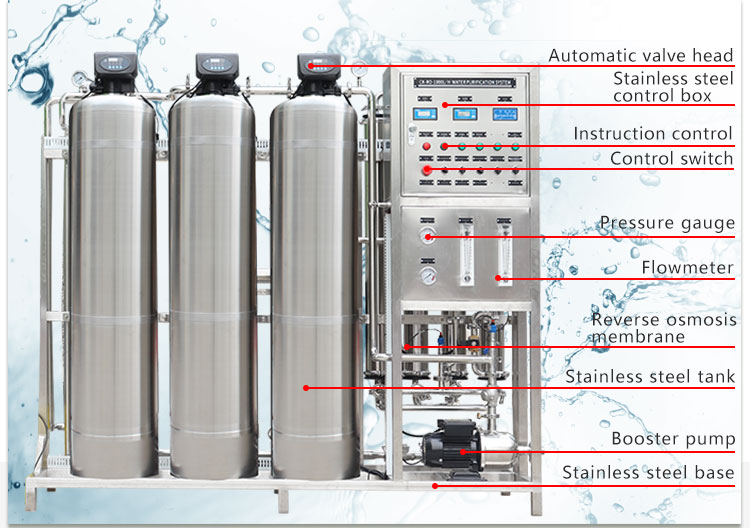

1. Reverse Osmosis (RO) System

The reverse osmosis system is one of the most commonly used primary water treatment equipment in the laboratory. It removes dissolved salts, organic matter and microorganisms from water through a semipermeable membrane to produce high-purity water. The RO system is usually used to remove most of the ions and particles in tap water, laying the foundation for the subsequent purification process. Although reverse osmosis water cannot meet the highest standards for laboratory water, it is the first step in preparing high-purity water.

RO systems are widely used in drinking water plant laboratories. For example, before conducting routine water quality testing, the laboratory may need a large amount of pure water to clean the equipment or dilute the sample, and reverse osmosis water can meet these needs.

2. Deionization (DI) system

The deionization system is a key device for further purifying water quality. Through cation exchange resin and anion exchange resin, the deionization system can remove the remaining ions in the water, including metal ions and inorganic ions. Water that has been deionized, usually called deionized water (DI water), has a higher purity than reverse osmosis water and is often used for high-precision chemical analysis.

In drinking water plant laboratories, deionized water is often used to prepare chemical reagents and clean experimental equipment to ensure that there will be no errors caused by impurities in the water during the analysis process. In addition, deionized water is also suitable for some more demanding biological experiments, such as water for culturing bacteria or algae.

3. Ultrapure water system

The ultrapure water system further purifies the water quality on the basis of reverse osmosis and deionization systems to meet the highest standards for laboratory water. The resistivity of ultrapure water usually reaches 18.2 MΩ·cm, which means that the impurity content in the water is extremely low. The ultrapure water system almost completely removes organic matter, ions, particles and microorganisms in the water through technologies such as multi-stage filtration, ion exchange and ultraviolet treatment.

In drinking water plant laboratories, ultrapure water is mainly used for extremely high-precision analysis, such as trace metal detection, nucleic acid extraction, and high-performance liquid chromatography (HPLC) analysis. These experiments have extremely strict requirements on water quality, and any impurities may have a significant impact on the results, so the use of ultrapure water is a necessary condition to ensure data accuracy.

4. Distilled water device

The distilled water device removes impurities from water by evaporation and condensation to obtain distilled water. Although the purity of distilled water is not as good as deionized water and ultrapure water, it is still very practical in some applications, especially when a large amount of pure water is required. Distilled water is often used to clean experimental equipment and some experiments that do not require ultra-high purity water.

In drinking water plant laboratories, distilled water devices can be used as a backup equipment to provide a basic supply of pure water to meet daily experimental needs. For example, when determining the total dissolved solids (TDS) or hardness in water samples, distilled water is usually used to dilute samples or rinse test tubes.

5. Activated carbon filter

Activated carbon filters are used to remove organic matter, residual chlorine, and some volatile organic compounds (VOCs) in water. Even if these substances are present in very low levels, they may interfere with experimental results. Therefore, activated carbon filters are usually used to pretreat raw water in the early stages of water treatment.

In drinking water plant laboratories, activated carbon filters are usually used in conjunction with reverse osmosis systems. Water filtered through activated carbon can extend the service life of reverse osmosis membranes and further reduce organic pollutants in water, ensuring the effectiveness of subsequent treatment steps.

6. Ultraviolet sterilizer

Ultraviolet sterilizers kill microorganisms in water through ultraviolet radiation, which is a physical disinfection method. The microbial content of laboratory water must be controlled at an extremely low level, especially when conducting microbial analysis or preparing sterile solutions. Therefore, ultraviolet sterilizers occupy an important position in water treatment equipment.

Ultraviolet sterilizers in drinking water plant laboratories are usually located at the end of deionized water or ultrapure water systems as the last line of defense to ensure that the final output water is pure and sterile.

Selection and application of water treatment equipment in drinking water plant laboratories

The selection of water treatment equipment in drinking water plant laboratories depends on experimental requirements and water quality standards. Generally speaking, laboratories will configure different types of water treatment equipment according to specific test items and water quality requirements to ensure that the water used in the experiment meets strict quality standards.

For example, if the laboratory is mainly engaged in chemical analysis, then deionized water and ultrapure water equipment are essential. For microbial analysis, ultraviolet sterilizers and water distiller may be more important. In actual operation, laboratories usually use a combination of water treatment equipment to ensure that pure water that meets the standards can be obtained in different experimental links.

In addition, equipment maintenance and monitoring are also crucial. Since the water quality of the laboratory directly affects the test results, laboratory managers must regularly check the operating status of the water treatment equipment to ensure that the equipment can continue to provide high-quality experimental water.

Case analysis: Application of water treatment equipment in drinking water plant laboratories

A large drinking water plant laboratory is equipped with a complete set of advanced water treatment equipment, including reverse osmosis systems, deionized water systems, and ultrapure water systems. These equipment provide a large amount of high-purity water to the laboratory every day, supporting a number of key water quality testing tasks.

In daily operations, the laboratory first uses a reverse osmosis system to preliminarily treat tap water to remove most of the dissolved salts and organic matter. Subsequently, the deionized water system further purifies the water quality to remove residual ions and metal impurities. For experiments that require the highest purity water, such as trace metal detection and nucleic acid analysis, laboratories use ultrapure water produced by ultrapure water systems.

This multi-level water treatment method not only ensures the purity of laboratory water, but also greatly reduces the risk of external interference with experimental data, thereby improving the accuracy and reliability of detection.

Conclusion

Drinking water plant laboratories have a heavy responsibility in ensuring water quality safety, and efficient and reliable water treatment equipment is an important guarantee for the normal operation of laboratories. By configuring appropriate water treatment equipment, laboratories can provide high-quality pure water for various tests, ensuring that every analysis is accurate and correct.