What is the difference between electrodeionization and traditional water treatment?

Water treatment technology plays a vital role in industry and life. Different water treatment methods have significant differences in the purification effects and treatment principles of water quality. In this news article, we will explore the main differences between electrodeionization and traditional water treatment, as well as their applications in industry and other fields.

What is the difference between electrodeionization and traditional water treatment?

The main difference between electrodeionization and traditional water treatment lies in the treatment principle and effect. Traditional water treatment usually relies on chemical substances or physical methods to remove impurities and microorganisms in water, while electrodeionization uses electrochemical principles to remove ions in water to achieve water purification. The water after electrodeionization treatment is purer and has no chemical residues. It is suitable for application fields that require high-purity water, such as the electronics industry, pharmaceuticals, etc.

The detailed differences are as follows:

●First, traditional water treatment often relies on chemicals, such as chlorine or chloride, to destroy microorganisms in the water and remove contaminants. This method may leave chemical residues that affect water quality and human health. Electrodeionization technology is a physical treatment method that does not require the addition of chemicals, so the treated water is purer and has no chemical residues.

●Secondly, traditional water treatment methods such as filtration and sedimentation often cannot completely remove dissolved solids and microorganisms in the water. Electrodeionization technology can effectively remove ions and microorganisms in water through ion exchange membranes or electrolyte solutions, making the treated water purer and safer.

●Thirdly, traditional water treatment methods often require a long treatment time and the treatment effect is unstable. Electrodeionization technology is efficient and fast, and can quickly remove harmful substances in water to ensure stable water quality after treatment.

●Finally, traditional water treatment methods usually require a large amount of chemicals and equipment investment, and the operating costs are high. Although the equipment cost of electrodeionization technology is higher, the cost is lower after long-term operation, and there is no need to add chemicals, saving later maintenance and operating costs.

How does electrodeionization technology achieve efficient water treatment?

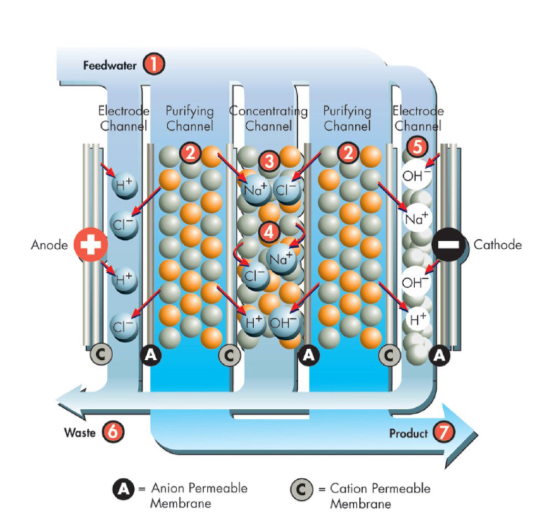

Electrodeionization technology uses an ion exchange membrane or electrolyte solution to use the action of an electric field to move ions in the water to the electrodes and then be removed, thereby purifying the water. Compared with traditional water treatment methods, electrodeionization technology has the following advantages:

1. High-purity water quality: Electrodeionization technology can effectively remove ions and dissolved solids in water to generate high-purity water quality that meets water quality standards in high-demand application fields.

2. No chemical residues: Since the electrodeionization process does not require the addition of chemicals, the treated water does not contain chemical residues and is safer and more reliable.

3. Energy saving and environmental protection: Compared with traditional water treatment methods, electrodeionization technology does not require a large amount of chemicals and high-energy-consuming equipment, and has lower energy consumption and environmental pollution.

Application of electrodeionization technology in industry

Electrodeionization technology is widely used in industry, mainly including the following aspects:

1. Electronics industry: In the electronics industry, high-purity water is needed to clean circuit boards and chips. Electrodeionization technology can provide high-purity water quality that meets the requirements.

2. Pharmaceutical industry: The pharmaceutical industry has very strict requirements on water quality. Electrodeionization technology can provide sterile, high-purity water without chemical residues for pharmaceutical production and water for injection.

3. Semiconductor industry: In the semiconductor industry, extremely high purity water is needed to clean silicon wafers and photoresists. Electrodeionization technology can meet these high water quality requirements.

4. Chemical production: In chemical production, electrodeionization technology can be used to remove ions and impurities in water to ensure the stability of the production process and product quality.

Summarize

Electrodeionization technology achieves efficient purification of water quality through electrochemical principles, with higher water purity and lower environmental impact than traditional water treatment methods. In applications in industry and other fields, electrodeionization technology plays an important role in providing high-quality water resources to various industries.