What is a flat sheet ultrafiltration membrane? What are its Pros and Cons?

In the context of the rapid development of water treatment technology today, ultrafiltration membrane technology has attracted much attention due to its efficient filtration performance and wide application prospects. Among them, as an important form of ultrafiltration membrane, flat sheet ultrafiltration membrane is emerging in more and more water treatment projects with its unique structure and superior performance.

So, what is a flat sheet ultrafiltration membrane? What are its advantages and disadvantages? This article will explore these issues in detail.

What is a flat sheet ultrafiltration membrane?

Flat sheet ultrafiltration membrane is a membrane separation technology that intercepts suspended matter, microorganisms, colloids and macromolecular organic matter in water under external pressure through a semipermeable membrane, thereby achieving the process of water purification. Unlike traditional tubular and hollow fiber ultrafiltration membranes, flat sheet ultrafiltration membranes adopt a flat structure design and are usually arranged and packaged in the form of flat sheet components.

What is the working principle of flat sheet ultrafiltration membrane?

The working principle of flat sheet ultrafiltration membrane is based on the selective permeability of the membrane. During the filtration process, the water to be treated passes through the flat ultrafiltration membrane under pressure. Water molecules and soluble substances smaller than the membrane pore size can pass through the membrane, while suspended matter, bacteria, viruses and macromolecular organic matter are retained on the membrane surface. The filtered purified water flows out from the other side of the membrane, and the retained pollutants form a concentrate.

Structure and material of flat ultrafiltration membrane

● Structure of flat ultrafiltration membrane:

Flat ultrafiltration membrane is usually composed of multiple flat membrane sheets, which are arranged in parallel at a certain distance to form a membrane assembly. Each membrane sheet is composed of a support layer and an active layer. The support layer provides mechanical strength, and the active layer is responsible for the filtration function. The channels between the membrane sheets allow water to flow through, forming a flow path inside the membrane assembly.

● Material of flat ultrafiltration membrane:

The material of flat ultrafiltration membrane is usually a high molecular polymer, such as polyvinylidene fluoride (PVDF), polysulfone (PS) and polyacrylonitrile (PAN). These materials have good chemical stability, mechanical strength and anti-pollution ability, and can maintain good performance in different water treatment environments.

What are the advantages of flat ultrafiltration membrane?

1. High-efficiency filtration performance:

The flat ultrafiltration membrane has a high filtration accuracy and can effectively intercept suspended matter, bacteria, viruses and macromolecular organic matter in the water. Its membrane pore size is usually between 0.01 and 0.1 microns, which can ensure the high purity of the effluent water quality.

2. Stable effluent water quality:

Since the filtration process of the flat ultrafiltration membrane mainly relies on physical interception, its effluent water quality is stable and is not easily affected by fluctuations in the raw water quality. Especially in the treatment of bacteria and viruses, the flat ultrafiltration membrane performs well and can ensure that the effluent meets the drinking water standards.

3. Easy maintenance:

The structural design of the flat ultrafiltration membrane assembly is easy to disassemble and clean, the maintenance process is simple, and there is no need to frequently replace the membrane assembly. This greatly reduces the operating and maintenance costs and improves the economy and reliability of the system.

4. Strong anti-pollution ability:

The flat ultrafiltration membrane material has good anti-pollution ability and can operate stably for a long time in an environment with high concentrations of organic matter and suspended matter. For pollutants on the membrane surface, the flat ultrafiltration membrane can also be effectively removed by backwashing, chemical cleaning and other means to restore the filtration performance of the membrane.

5. Small footprint:

The flat ultrafiltration membrane assembly has a compact structure and a small footprint, making it suitable for water treatment projects with limited space. Its modular design can be flexibly adjusted according to the treatment scale to meet the water treatment needs of different scales.

What are the disadvantages of flat ultrafiltration membranes?

1. High initial investment:

The initial investment of the flat ultrafiltration membrane system is high, especially the high-quality flat ultrafiltration membrane assembly and supporting equipment are relatively expensive. This may pose a certain economic pressure for water treatment projects with limited budgets.

2. High energy consumption:

The operation of the flat ultrafiltration membrane requires a certain pressure drive, and usually requires the installation of efficient pumps and pressure vessels, so the energy consumption of the system is relatively high. Against the background of rising energy costs, this factor may affect the long-term economy of the system.

3. Membrane fouling problem:

Although the flat ultrafiltration membrane has a strong anti-pollution ability, membrane fouling is still an inevitable problem in long-term operation. Membrane fouling will lead to a decrease in flux and reduced filtration efficiency, and regular chemical cleaning and maintenance are required, which increases the operation and maintenance costs.

4. High requirements for pretreatment:

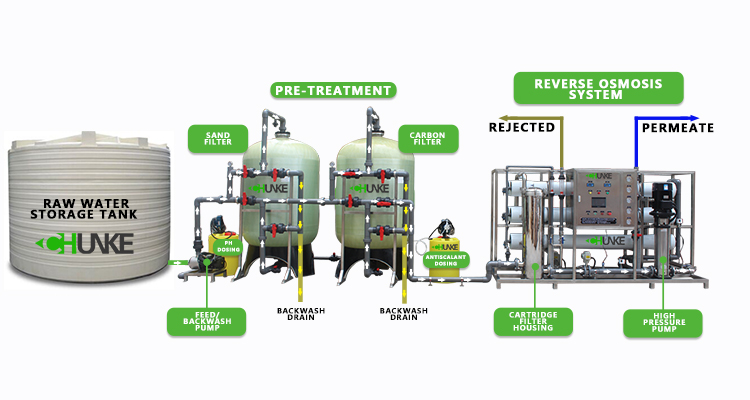

In order to ensure the long-term operation of the flat ultrafiltration membrane and the quality of the effluent, the pretreatment of the raw water is particularly important. If the raw water contains a large amount of large particles or high concentrations of organic matter, it may cause rapid contamination and damage to the membrane components. Therefore, a good pretreatment system is a prerequisite for the efficient operation of the flat ultrafiltration membrane system.

Application areas of flat ultrafiltration membranes

1. Drinking water treatment:

Flat ultrafiltration membranes have broad application prospects in drinking water treatment. Its efficient microbial retention capacity and stability of effluent water quality make it an ideal choice for urban water supply and rural drinking water purification.

2. Industrial wastewater treatment:

In the field of industrial wastewater treatment, flat ultrafiltration membranes can effectively remove suspended matter and organic pollutants in wastewater, and are suitable for wastewater treatment in electroplating, textile, pharmaceutical and other industries. Its compact structure and efficient treatment capacity also make it suitable for industrial wastewater reuse projects.

3. Agricultural irrigation water:

Flat ultrafiltration membranes also show good application potential in agricultural irrigation water treatment. Irrigation water treated by ultrafiltration technology can remove suspended matter and pathogenic microorganisms in the water and protect the healthy growth of crops.

4. Wastewater reuse:

In the field of wastewater reuse, flat ultrafiltration membrane technology can effectively improve the water quality of recycled water and reduce dependence on freshwater resources, which has important environmental protection significance and economic benefits.

Conclusion

As an efficient and stable water treatment technology, flat ultrafiltration membrane has shown broad application prospects in drinking water treatment, industrial wastewater treatment and wastewater reuse due to its unique structure and superior performance.

Although it has problems such as high initial investment, high energy consumption and membrane pollution, these problems can be effectively solved through scientific design and reasonable maintenance.