How much does it cost to build a bottled drinking water plant?

The bottled drinking water market has boomed in recent years and has become one of the fastest growing areas in the global beverage industry. More and more consumers are choosing bottled water as their primary source of drinking water, and this trend has inspired many entrepreneurs and investors to consider starting a bottled water plant.

However, setting up a bottled drinking water plant involves a lot of upfront investment and complex equipment selection. So, how much does it cost to build a bottled drinking water plant? What key equipment do you need to buy in the process? This article will explore this in detail.

How much does it cost to build a bottled drinking water plant?

The cost of setting up a bottled drinking water plant varies depending on factors such as geographical location, production scale, equipment selection, and market positioning. Generally speaking, the initial investment of a small or medium-sized bottled water plant includes land acquisition or leasing, plant construction, equipment procurement, raw material procurement, employee recruitment and training, and operating license processing.

Preliminary cost estimate for plant construction

1. Land and plant construction

Land and plant are the most basic investment parts. Land prices vary from region to region. In some developing countries, land costs may be relatively low, while in developed countries or large cities, land prices may be a large part of the total investment. A small or medium-sized bottled water plant usually requires 500 to 2,000 square meters of plant space. Depending on the land prices in different regions, the cost of land and plant construction may range from US$50,000 to US$500,000.

2. Equipment procurement

Equipment procurement is the core investment part of a bottled water plant and accounts for a large proportion of the total cost. The quality and production capacity of the equipment will directly affect the plant's production capacity and product quality. The following will detail the main equipment required for a bottled water plant and its approximate price.

3. Raw materials and operating costs

Raw materials (such as water sources, bottles, labels, and packaging materials) are the basis for ongoing operations. Although these costs are not one-time investments, a large amount of raw materials may need to be purchased during the startup phase to ensure smooth production. Initial raw material and operating costs are usually between US$20,000 and US$100,000.

4. Staff costs

Hiring and training staff is also an important cost. Bottled water plants usually require several employees including production workers, quality control personnel, technicians and management personnel. Initial employee costs may range from $10,000 to $50,000, depending on the size of the plant and local wage levels.

5. Licenses and legal fees

In most countries, setting up a bottled water plant requires obtaining a series of licenses and passing quality inspections. These licenses may include health permits, production permits, environmental assessment reports, etc. These procedures may incur costs of $5,000 to $20,000.

In summary, the initial investment to set up a small or medium-sized bottled water plant is usually between $150,000 and $1,000,000. The specific investment amount will vary depending on the geographical location and production scale.

What equipment do I need to buy to build a bottled drinking water plant?

The production process of a bottled drinking water plant is relatively complex, and a series of professional equipment is required to ensure water quality, packaging and output. The following are the main equipment that a bottled water plant usually needs:

1. Water treatment system

The water treatment system is the core equipment of a bottled water plant, ensuring that the water obtained from natural water sources meets the quality standards of drinking water. A typical water treatment system includes the following parts:

● Coarse filter: used to remove large particles of impurities such as sand, dirt and rust in the water.

● Activated carbon filter: used to remove organic matter, residual chlorine and odor in the water.

● Reverse osmosis system: through semi-permeable membrane filtration, remove dissolved salts and harmful substances in the water to make the water reach the standard of pure water.

● Ultraviolet sterilizer: Use ultraviolet rays to kill microorganisms in the water to ensure the sterility of the water.

● Ozone generator: used for final disinfection to prevent bacteria from multiplying in the bottle.

The price of a complete water treatment system usually ranges from 30,000 to 200,000 US dollars, depending on the size and complexity of the system.

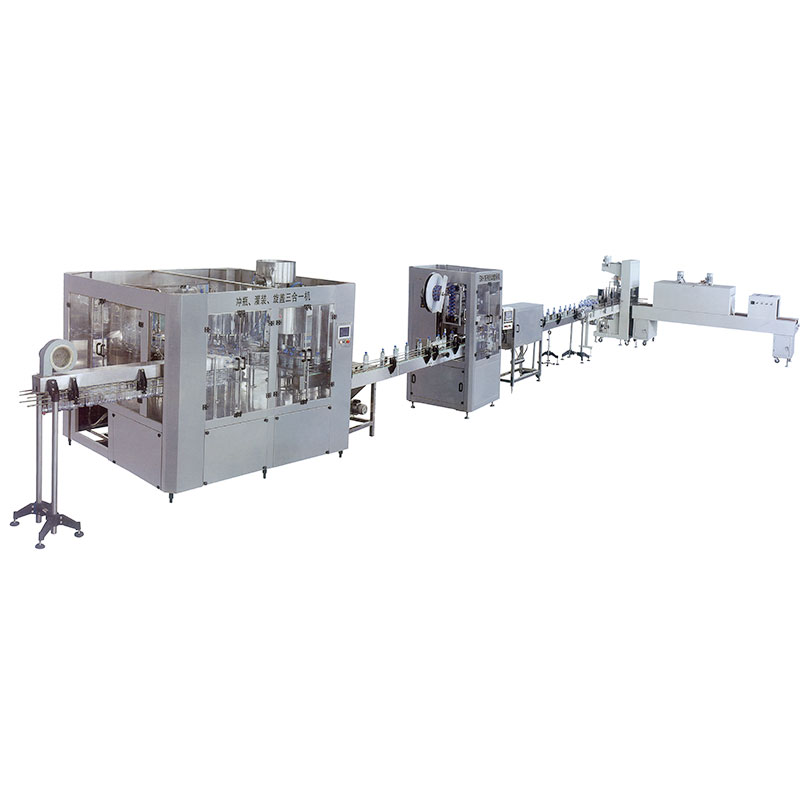

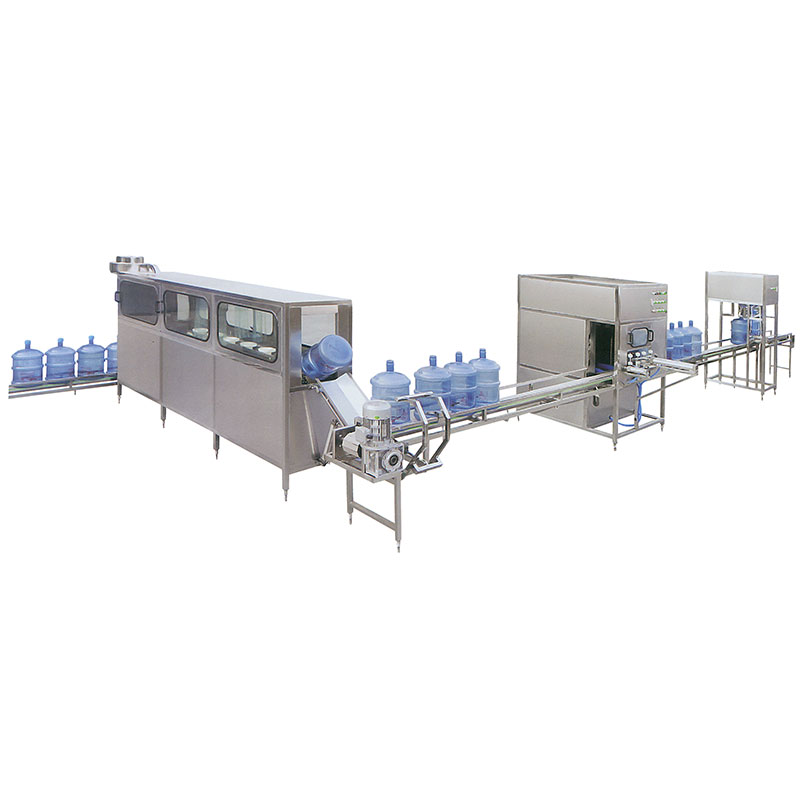

2. Filling machine

The filling machine is the equipment that fills the treated water into the bottle. The price of the filling machine varies depending on the type and degree of automation. Common filling machines include semi-automatic filling machines and fully automatic filling machines, the latter of which are suitable for large-scale production. The price of fully automatic filling machines usually ranges from US$20,000 to US$150,000.

3. Blow molding machine

Blow molding machines are used to blow plastic preforms (embryo bottles) into the final bottle shape. These plastic bottles are usually made of PET (polyethylene terephthalate) material, which is lightweight, transparent and low-cost. The price of blow molding machines generally ranges from US$10,000 to US$100,000, depending on the capacity and degree of automation.

4. Labeling machine

Labeling machines are used to attach brand labels and production dates to bottles. Automatic labeling machines can significantly improve production efficiency, especially when the production volume is large. The price of labeling machines usually ranges from US$5,000 to US$50,000.

5. Packaging equipment

Packaging equipment includes case packers and case sealers, which are used to pack bottled water into boxes for easy transportation and sales. The price of these equipment is generally between $10,000 and $50,000.

6. Inspection equipment

In order to ensure that the water quality meets the standards, bottled water plants usually need to be equipped with a series of water quality testing equipment, such as pH meters, conductivity meters, turbidity meters, microbial testing equipment, etc. The total price of these equipment is usually between $5,000 and $30,000.

7. Other auxiliary equipment

Other necessary equipment includes air compressors, conveyor belts, water storage tanks, boilers, etc. Although these equipment are not directly involved in the water production process, they are essential for the smooth operation of the entire production line. The total cost of these auxiliary equipment is usually between $10,000 and $50,000.

Case analysis: Construction cost of a medium-sized bottled water plant

Assume that a medium-sized bottled water plant is established in the central United States, with the goal of producing 3,000 bottles of 500 ml bottled water per hour. The following is a rough cost analysis of this project:

● Land and plant: Purchase a 1,000 square meter piece of land and build a plant, estimated at $200,000.

● Water treatment system: Purchase a water treatment system with a processing capacity of 3,000 liters/hour at a cost of $100,000.

● Filling machine: Purchase a fully automatic filling machine at a cost of $100,000.

● Blow molding machine: Purchase a medium-capacity blow molding machine at a cost of $50,000.

● Labeling machine: Purchase a fully automatic labeling machine at a cost of $20,000.

● Packaging equipment: Purchase automated packaging equipment at a cost of $30,000.

● Inspection equipment: Equip with necessary water quality testing equipment at a cost of $20,000.

● Auxiliary equipment: Purchase equipment such as conveyor belts, water storage tanks and air compressors at a cost of $30,000.

In total, the initial investment for this medium-sized bottled water plant is about $550,000. In addition, additional costs such as operating funds, personnel training and licenses need to be considered.

Conclusion

Building a bottled drinking water plant requires a large initial investment, and the selection and configuration of equipment are crucial to the plant's operating efficiency and product quality. From water treatment systems to filling, blowing, labeling and packaging, each link requires the support of precision equipment.

Understanding the functions and costs of these equipment can help investors make wise decisions to ensure the successful start-up and stable operation of the project.