Industrial ionized water machine vs. reverse osmosis system, is there any difference?

In water treatment technology, industrial ionized water machine and reverse osmosis system are two common treatment equipment. They differ in application field, working principle and treatment effect. Understanding the difference between these two systems will help enterprises or individuals choose the most suitable water treatment solution according to specific needs.

What is the working principle of industrial ionized water machine?

Industrial ionized water machine mainly separates ordinary water into alkaline water and acidic water by electrolyzing water. Its working principle is based on the electrolysis process. When the current passes through the water, the minerals and ions in the water are separated and gathered on different electrodes according to the polarity of the electrodes.

● Alkaline water: On the anode side, alkaline minerals (such as calcium, magnesium, potassium, etc.) in the water are attracted to generate alkaline water. This water is usually used for drinking or as a cleaning solution.

● Acidic water: On the cathode side, acidic minerals (such as sulfate, chloride, etc.) are attracted to generate acidic water. This water is usually used for disinfection, sterilization or industrial cleaning.

Industrial ion water machine can control the pH value and mineral concentration of generated water by adjusting the voltage, current and water flow rate of electrolysis to meet different needs.

What is the working principle of reverse osmosis system?

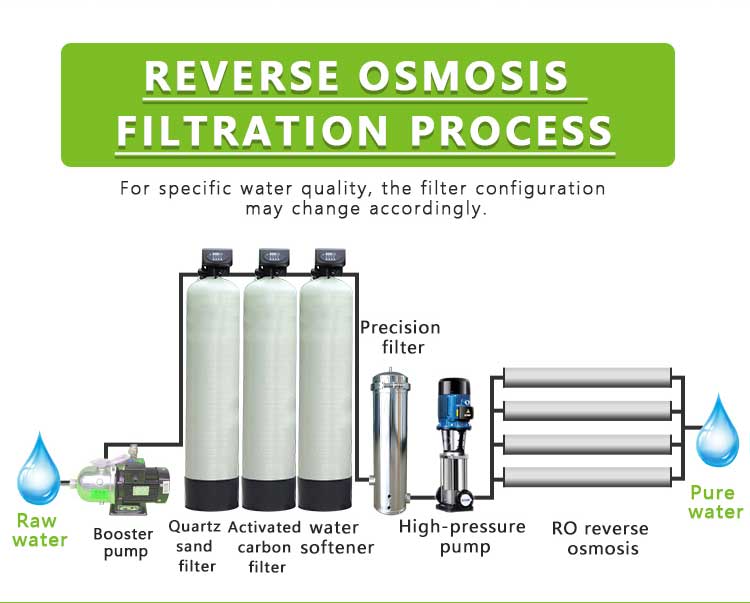

The reverse osmosis (RO) system adopts a different water treatment principle. Reverse osmosis is a physical separation technology that uses the characteristics of semipermeable membranes to separate solutes (such as salt, heavy metals, organic matter, etc.) from solvents (water) by applying pressure.

● Semipermeable membrane: Reverse osmosis membrane is a membrane with extremely fine pores, usually around 0.0001 microns. Water molecules can pass through these pores, while most impurities dissolved in water are retained.

● Apply pressure: In the reverse osmosis process, sufficient pressure (usually tens to hundreds of atmospheres) needs to be applied to overcome the osmotic pressure of water and allow water molecules to pass through the semipermeable membrane to achieve purification.

The reverse osmosis system can effectively remove various soluble solids, bacteria, viruses and organic matter in water, and is currently one of the most sophisticated filtration methods in the field of water treatment.

Industrial ionized water machine vs. reverse osmosis system, what is the difference?

Different treatment targets:

● Industrial ionized water machine: mainly used to adjust the pH value and mineral content of water, suitable for application scenarios that require the generation of specific pH water quality, such as food processing, cleaning, medical fields, etc.

● Reverse osmosis system: mainly used to remove soluble solids and organic pollutants in water, the goal is to obtain pure water, widely used in drinking water purification, industrial water treatment and laboratory water and other fields.

Different working principles:

● Industrial ionized water machine: based on the principle of electrolysis, the distribution of ions in water is changed through the action of electrodes to generate water with different pH values.

● Reverse osmosis system: based on the principle of physical separation, the dissolved substances in water are removed through the selective filtration of semipermeable membranes.

Different application areas:

● Industrial ionized water machine: suitable for occasions where the pH value of water quality needs to be adjusted, such as food processing plants, hospitals, electronic manufacturing industries, etc. It separates and adjusts the mineral components of water to generate alkaline or acidic water suitable for specific purposes.

● Reverse osmosis system: suitable for occasions with extremely high requirements for water purity, such as household drinking water purification, pharmaceutical production, electronic semiconductor manufacturing, etc. It can provide ultra-high purity water and remove almost all soluble impurities.

Different water treatment effects:

● Industrial ion water machine: mainly changes the characteristics of water by adjusting the pH value of water to separate the minerals in the water, but does not completely remove soluble solids.

● Reverse osmosis system: can remove more than 99% of soluble solids, heavy metals, bacteria and viruses in water, and provide a treatment effect close to pure water.

Different operating costs and maintenance:

● Industrial ion water machine: The operating cost is low, but the electrodes need to be cleaned regularly and the electrolysis effect needs to be checked. The quality of electrode materials and electrolytes has a great impact on the life of the equipment and the treatment effect.

● Reverse osmosis system: The operating cost is high, mainly reflected in the energy consumption of the pump and the replacement of the reverse osmosis membrane. The reverse osmosis membrane needs to be cleaned or replaced regularly to maintain the filtration effect. In addition, the reverse osmosis system has high requirements for the quality of the incoming water, and usually requires a pre-filter device for pretreatment.

Comparison of the advantages and disadvantages of the two systems

What are the advantages and disadvantages of industrial ionized water machines?

Advantages of industrial ionized water machines:

● Capable of producing water with different pH values, flexible in application.

● Simple equipment, easy to operate and maintain.

● Suitable for specific occasions where alkaline or acidic water needs to be generated.

Disadvantages of industrial ionized water machines:

● Cannot completely remove dissolved solids and organic matter in water.

● High requirements for inlet water quality, water with too high hardness may affect the electrolysis effect.

What are the advantages and disadvantages of reverse osmosis systems?

Advantages of reverse osmosis systems:

● Capable of providing extremely high purity water, removing most dissolved solids and pollutants.

● Wide range of applications, suitable for a variety of water treatment needs.

Disadvantages of reverse osmosis systems:

● High equipment cost and high operating energy consumption.

● Requires regular maintenance of reverse osmosis membranes to avoid membrane clogging and performance degradation.

How to choose a suitable system?

Whether to choose an industrial ionized water machine or a reverse osmosis system depends on the specific water treatment needs and application scenarios.

● If you need to adjust the pH value of water to generate specific alkaline or acidic water, and do not need highly pure water quality, industrial ion water machine is an ideal choice. It is suitable for food processing, cleaning, agricultural irrigation and other occasions, in which the pH value and mineral content of water are crucial.

● If you need to remove pollutants such as dissolved solids, heavy metals, bacteria, etc. in water to obtain nearly pure water, the reverse osmosis system is more suitable. It is suitable for household drinking water purification, industrial ultrapure water production, and medical and laboratory water use.

In addition, considering the operating cost, maintenance requirements and service life of the equipment are also important factors in selection. For occasions with limited budgets and low water quality requirements, industrial ion water machines may be more cost-effective. In the field of high-precision water treatment, the advantages of reverse osmosis systems are more prominent.