What is the role of an industrial water treatment plant?

Industrial water treatment plants play a vital role in modern industry. They are responsible for treating industrial wastewater, ensuring that the quality of the discharged water meets environmental protection standards and minimizing the impact on the environment. This article will focus on the role and work process of industrial water treatment plants, elaborate on their importance in purifying industrial wastewater, and further explore the challenges and development trends faced by industrial water treatment plants.

What is the role of an industrial water treatment plant?

The main function of industrial water treatment plants is to purify industrial wastewater and ensure that its discharge meets environmental protection standards, thereby reducing environmental pollution. Different types of industrial activities produce a wide variety of wastewater, including chemicals, heavy metals, organic matter, etc. Direct discharge of these wastewater without treatment will pose serious threats to water bodies, soil and biodiversity.

What is the workflow?

The work flow of industrial water treatment plants is usually divided into five stages: pretreatment, primary treatment, secondary treatment, tertiary treatment, and disinfection:

1. Pretreatment:

The pretreatment stage is mainly to remove large particles and impurities in wastewater. This can be achieved by screening, filtration or sedimentation.

2. Primary treatment:

In the primary treatment stage, suspended solids and organic matter in wastewater are removed through physical and chemical methods. This may include the addition of chemicals for coagulation and flocculation, and the use of settling tanks to remove sediment.

3. Secondary treatment:

Secondary treatment is a critical stage in removing dissolved organic matter and nutrients from wastewater. Biological treatment technologies are usually used, such as activated sludge, oxidation ditch or biofilm.

4. Tertiary treatment:

Tertiary treatment further purifies wastewater and removes tiny particles, nutrients such as nitrogen and phosphorus, and organic pollutants. This stage usually uses techniques such as chemical precipitation, filtration or activated carbon adsorption.

5. Disinfection:

In the final stage, wastewater is usually disinfected through chlorine disinfection, ultraviolet disinfection or ozone disinfection to ensure that pathogens in the wastewater are killed.

The workflow of an industrial water treatment plant is adapted to different industrial activities and the nature of the wastewater, but in general wastewater is purified through a series of treatment steps to a level that meets standards.

What key process technologies are used in industrial water treatment plants?

Industrial water treatment plants use a variety of key process technologies to treat wastewater, which vary based on the composition of the wastewater and treatment objectives. Common process technologies include activated sludge method, biofilm method, membrane separation technology, denitrification and dephosphorus technology, disinfection technology, etc.

1. Activated sludge method: This is a common secondary treatment technology that uses the metabolic action of microorganisms to remove organic matter and nutrients from wastewater. The activated sludge method has the advantages of good treatment effect and stable operation.

2. Biofilm method: The biofilm method includes trickling filters and biological turntables, which treat wastewater by forming a biofilm on the medium. The biofilm method is suitable for wastewater treatment with high organic load.

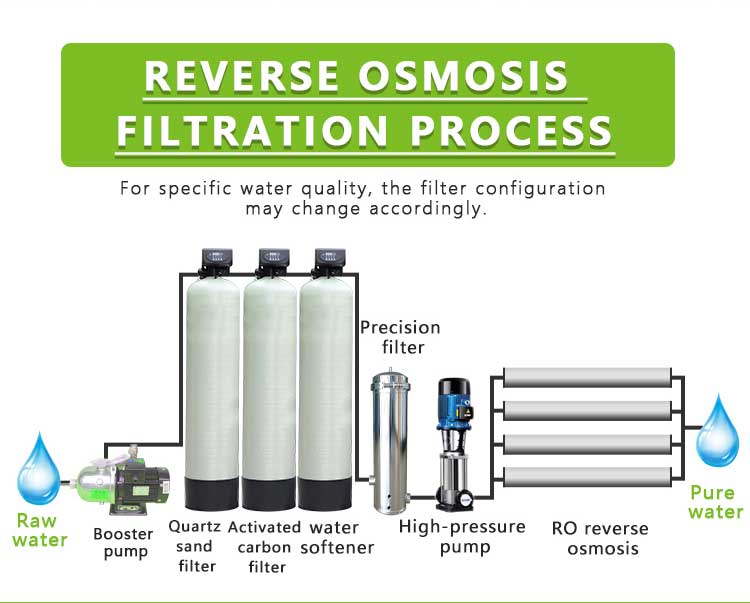

3. Membrane separation technology: Including microfiltration, ultrafiltration, nanofiltration and reverse osmosis. These technologies separate suspended solids, bacteria, viruses and dissolved pollutants in wastewater through semi-permeable membranes to provide high-quality effluent.

4. Denitrification and dephosphorus technology: Denitrification and dephosphorus are the key processes for removing nitrogen and phosphorus from wastewater. If these nutrients are not removed, they will lead to eutrophication of water bodies and cause ecological and environmental problems.

5. Disinfection technology: Disinfection is an important step in killing pathogens in wastewater. Commonly used disinfection methods include chlorine disinfection, ultraviolet disinfection and ozone disinfection.

The combination of these key process technologies enables industrial water treatment plants to adopt appropriate treatment methods according to different types of wastewater to ensure that the quality of discharged water reaches standards.

What are the challenges faced by industrial water treatment? What are the solutions?

Industrial water treatment faces many challenges, including handling complex wastewater, controlling costs, regulations and standards, sludge treatment, etc.

1. Treatment of complex wastewater: Industrial wastewater may contain a variety of toxic substances, heavy metals and refractory organic matter, making treatment difficult.

2. Control costs: Treating complex wastewater requires a variety of technologies and equipment, resulting in higher operating and maintenance costs.

3. Regulations and standards: Different regions have different regulations and standards for industrial wastewater discharge, and treatment plants need to meet different requirements.

4. Sludge treatment: Sludge treatment and disposal are by-products of water treatment. Improper treatment may cause secondary pollution.

Solving these challenges requires a series of innovations and technological improvements, including technology upgrades, intelligent management, resource recycling, policy support, etc.

1. Technology upgrade: Introduce new technologies and processes, such as advanced oxidation technology, catalysts and nanomaterials, to improve wastewater treatment effects.

2. Intelligent management: Use the Internet of Things and data analysis to realize intelligent management of water treatment plants, optimize operational efficiency and save costs.

3. Resource recovery: Improve the utilization value of wastewater by recycling resources in wastewater, such as heavy metals, nutrients and energy.

4. Policy support: The government should introduce corresponding policies to encourage and support technological innovation and cost control of water treatment plants.

Summary: Industrial water treatment plants play a vital role in modern industrial production, reducing the impact of industry on the environment through effective wastewater treatment and resource recovery. Faced with challenges such as processing complex wastewater and cost control, water treatment plants need to continuously innovate and improve technology. Through intelligent management and policy support, industrial water treatment plants can improve operational efficiency and achieve sustainable development.