What is the most effective industrial water filtration system?

In order to protect the environment and improve the reuse rate of water resources, the selection and application of industrial water filtration systems have become particularly important. An effective water filtration system can not only significantly reduce production costs, but also improve product quality and reduce environmental pollution.

So, what is the most effective industrial water filtration system? This article will explore this issue from multiple angles and analyze in detail several common industrial water filtration systems and their advantages and disadvantages.

The necessity of industrial water filtration systems

A large amount of wastewater will be generated during industrial production, which contains various pollutants such as suspended solids, grease, heavy metals, chemicals, etc. If these pollutants are discharged directly without treatment, they will not only cause serious damage to the environment, but also lead to waste of water resources. Therefore, the application of industrial water filtration systems has become an indispensable link. An effective water filtration system can:

1. Remove pollutants from water and meet emission standards.

2. Improve the reuse rate of water and save water resources.

3. Protect production equipment and extend its service life.

4. Reduce production costs and improve economic benefits.

What types of industrial water filtration systems are there?

5 common industrial water filtration systems:

1. Sand Filter,

2. Activated Carbon Filter,

3. Microfiltration and Ultrafiltration,

5. Magnetic Filter.

1. Sand Filter:

Sand filter is a traditional water filtration equipment that uses the physical interception effect of the sand layer to remove suspended matter and particulate matter in the water. It has a simple structure, easy operation and maintenance, and low cost.

Advantages of Sand Filter:

● Simple structure, easy operation and maintenance.

● Low operating cost.

● Can effectively remove large suspended particles.

Disadvantages of Sand Filter:

● Low filtration accuracy, unable to remove tiny particles and soluble pollutants.

● Requires regular backwashing, and high water consumption.

2. Activated Carbon Filter:

Activated carbon filter uses the adsorption capacity of activated carbon to remove organic matter, residual chlorine and odor from water. The porous structure of activated carbon gives it a large specific surface area, which can effectively adsorb pollutants in water.

Advantages of activated carbon filter:

● Good removal effect on organic matter, residual chlorine and odor.

● Improve the taste and smell of water.

Disadvantages of activated carbon filter:

● Limited adsorption capacity, activated carbon needs to be replaced regularly.

● Poor removal effect on suspended matter and heavy metals.

3. Microfiltration and ultrafiltration:

Microfiltration and ultrafiltration are a type of membrane separation technology. Through the screening effect of microporous membranes or ultrafiltration membranes, suspended matter, bacteria and some viruses in water are removed. It has high filtration accuracy and can effectively remove tiny particles and microorganisms.

Advantages of microfiltration and ultrafiltration:

● High filtration accuracy, can remove bacteria and some viruses.

● No need to add chemical agents, environmentally friendly and safe.

Disadvantages of Microfiltration and Ultrafiltration:

● The membrane is easily contaminated and needs to be cleaned or replaced regularly.

● The operating cost is high.

4. Reverse Osmosis System:

The reverse osmosis system is a highly efficient membrane separation technology that removes dissolved salts, heavy metals, chemicals and microorganisms in water through the osmotic action of a semipermeable membrane. Its filtration accuracy is extremely high, and it can effectively remove various pollutants. It is widely used in various high-demand water treatment occasions.

Advantages of Reverse Osmosis System:

● The filtration accuracy is extremely high, and most pollutants can be removed.

● The effluent water quality is excellent, suitable for high-demand water treatment.

Disadvantages of Reverse Osmosis System:

● The initial investment and operating cost are high.

● The pretreatment requirements are high, and multi-stage filtration is required.

5. Magnetic Filter:

The magnetic filter uses magnetic force to remove ferromagnetic particles in water, such as iron filings and rust. Its structure is simple and easy to operate, and it is particularly suitable for the treatment of industrial wastewater containing ferromagnetic impurities.

Magnetic filter (Magnetic Filter) Advantages:

● Good removal effect on ferromagnetic particles.

● Simple structure, easy operation and maintenance.

Magnetic filter (Magnetic Filter) Disadvantages:

● Can only remove ferromagnetic particles, ineffective for other pollutants.

What is the most effective industrial water filtration system?

The most effective industrial water filtration system-comprehensive multi-stage filtration system

Considering the advantages and disadvantages of various filtration systems, a single filtration system is often difficult to meet the complex requirements of industrial wastewater treatment. Therefore, the most effective industrial water filtration system is usually a comprehensive multi-stage filtration system composed of multiple filtration technologies. This system combines the advantages of multiple filtration technologies and can efficiently and comprehensively remove various pollutants.

What are the components of a comprehensive multi-stage filtration system?

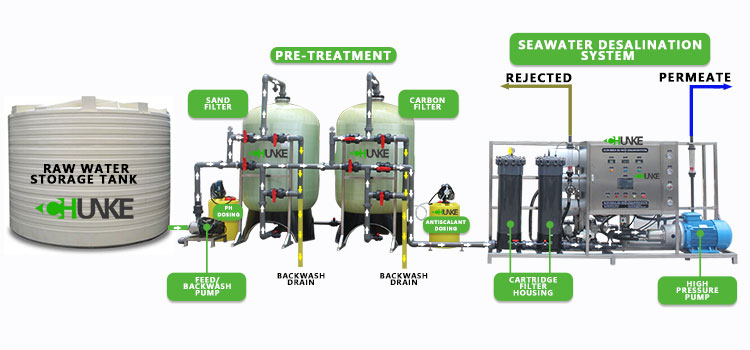

A typical comprehensive multi-stage filtration system usually includes a pretreatment unit, a fine filtration unit, and a deep treatment unit. The specific introduction is as follows:

● Pretreatment unit: Use sand filters, magnetic filters and other equipment to remove large suspended solids and ferromagnetic particles, reducing the load of subsequent treatment equipment.

● Fine filtration unit: Use microfiltration, ultrafiltration and activated carbon filters to further remove fine particles, organic matter and residual chlorine in the water to improve water quality.

● Deep treatment unit: Use reverse osmosis system to remove dissolved salts, heavy metals and microorganisms in the water to ensure that the effluent water quality meets high standards.

What are the advantages of a comprehensive multi-stage filtration system?

Advantages of a comprehensive multi-stage filtration system: high efficiency, flexibility and reliability.

● High efficiency: The multi-stage filtration system combines the advantages of various filtration technologies and can comprehensively and efficiently remove various pollutants.

● Flexibility: According to the specific water quality and treatment requirements, the configuration of each level of filtration units can be flexibly adjusted to ensure the best treatment effect.

● Reliability: The units at each level of the multi-stage filtration system cooperate with each other to effectively cope with various complex water quality conditions and ensure the stable operation of the system.

Example analysis of comprehensive multi-stage filtration system

Take the wastewater treatment project of a large chemical enterprise as an example. The enterprise's wastewater contains a large amount of suspended solids, heavy metals and organic pollutants. After many technical demonstrations, a comprehensive multi-stage filtration system was finally selected.

● Pretreatment stage: Sand filter and magnetic filter are used to remove large suspended solids and ferromagnetic particles.

● Fine filtration stage: Microfiltration and activated carbon filter are used to further remove fine particles and organic matter.

● Deep treatment stage: Reverse osmosis system is used to remove dissolved salts and heavy metals in water to ensure that the effluent water quality meets the discharge standards.

After the system was put into operation, the wastewater treatment effect was significant, the effluent water quality was greatly improved, the production cost was significantly reduced, and good economic and environmental benefits were achieved.

Conclusion on the most effective industrial water filtration system

The most effective industrial water filtration system is often not a single device, but a comprehensive multi-stage filtration system composed of multiple filtration technologies. By rationally configuring and optimizing the filtration units at all levels, various pollutants can be removed efficiently and comprehensively to meet the complex industrial wastewater treatment needs.