What kind of water filtration system is used in hospital clinics?

Hospitals are a special environment, and the medical process has extremely strict requirements on water quality. In different clinical application scenarios, hospitals need to adopt a variety of water filtration systems to ensure that the water quality meets the medical grade standards. This not only involves the direct treatment of patients, but also the maintenance and disinfection of medical equipment.

This article will discuss in detail the main water filtration systems used in hospital clinics, including their principles, functions and their applications in the medical field.

What are the basic requirements for hospital water quality?

In hospitals, water is used in many key links, such as ward water, operating room water, equipment cleaning, laboratory analysis, hemodialysis, etc. For these uses, the water quality requirements vary, but in general, they must reach extremely high purity to prevent contamination and cross-infection. Hospital water must be sterile, especially in scenarios that come into direct contact with patients, such as hand washing, wound cleaning, instrument disinfection, etc. If microorganisms in water cannot be controlled, they may cause nosocomial infections and endanger the health of patients.

Chemical pollutants in water, including heavy metals, chlorides and other chemicals, must be controlled at extremely low levels. These chemicals may not only directly cause toxic effects on patients, but may also affect the dilution of drugs and the accuracy of experimental results. Suspended particles may not only damage medical equipment, but may also be directly introduced into the patient's body during infusion or other invasive operations, posing health risks. Therefore, the control of particulate matter is another important aspect of hospital water quality standards.

What kind of water filtration system is used in hospital clinics?

In order to meet the above requirements, hospitals usually use multi-stage filtration systems. These systems work together to ensure that the water quality can meet the corresponding standards in different usage scenarios. The following are several water filtration systems commonly used in hospitals:

Reverse Osmosis (RO) System

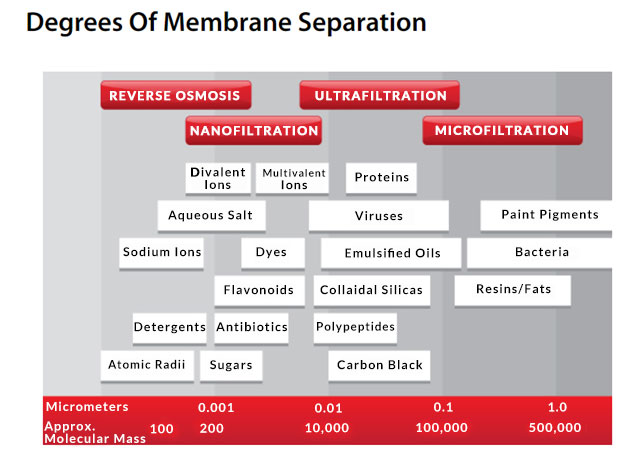

The reverse osmosis system is one of the most common water filtration systems in hospitals. Its working principle is to remove ions, molecules and larger particulate matter from water through the selective permeability of the semipermeable membrane.

● Working principle: The reverse osmosis system squeezes water through the semipermeable membrane under high pressure. The diameter of the membrane pore is extremely small, and only water molecules and a very small number of small molecules can pass through, while most soluble salts, organic matter, bacteria and viruses are blocked on the other side of the membrane to form a concentrated liquid for discharge.

● Application scenarios: Reverse osmosis water is usually used to prepare injections, infusions and dialysate. The quality of dialysis water directly affects the health of dialysis patients. Therefore, the reverse osmosis system occupies a core position in the dialysis center. In addition, reverse osmosis water is also used for cleaning and disinfection of equipment in the operating room to ensure that there are no residual impurities on the surface of the equipment.

● Maintenance and management: The reverse osmosis system requires regular maintenance, mainly including membrane cleaning and replacement. During long-term use, the membrane surface may be scaled by calcium and magnesium ions, and chemical cleaning is required to restore its filtration performance.

Ultrafiltration (UF) system

The ultrafiltration system is a system that uses a membrane with a larger pore size for filtration. It is mainly used to remove larger particles such as microorganisms, colloids, and suspended matter in water.

● Working principle: The membrane pore size of the ultrafiltration system is usually between 0.01 microns and 0.1 microns, which can effectively remove bacteria, viruses and most particulate matter. However, due to its large pore size, it cannot effectively remove ions and smaller organic matter.

● Application scenarios: Ultrafiltration water is often used for general medical water, such as ward washing, toilet water and some laboratory water. It can also be used as a pretreatment step for reverse osmosis systems to remove most suspended solids, reduce the burden on reverse osmosis membranes, and extend their service life.

● Maintenance and management: The membranes of ultrafiltration systems are easily clogged by suspended solids and colloids, so they need to be backwashed and cleaned regularly. The frequency of membrane replacement depends on the water quality, usually once a year.

Deionized (DI) water system

The deionized water system removes ions from water through cation exchange resins and anion exchange resins to produce pure water or ultrapure water.

● Working principle: The deionized water system uses the characteristics of ion exchange resins to exchange cations (such as calcium, magnesium, sodium) and anions (such as chloride, sulfate, bicarbonate) in water, thereby removing them from the water. The final water produced contains almost no soluble salts and has extremely low conductivity, close to theoretical pure water.

● Application scenarios: Deionized water is widely used in laboratory analysis, pharmaceutical formulations, and sensitive equipment cleaning. Due to its extremely high purity, deionized water is particularly important in chemical analysis and biological experiments that require no ion interference.

● Maintenance and management: Deionized water systems require regular regeneration. As the resin bed becomes saturated with use, chemical regeneration is required to restore its exchange capacity. The regeneration process uses acid and alkaline solutions, and the operation needs to be cautious to avoid system contamination.

Activated carbon filtration system

The activated carbon filtration system removes organic matter, chlorine, odor and some heavy metals from water through adsorption.

● Working principle: The surface area of activated carbon is very large, and the internal pore structure is complex. It can capture organic molecules and some inorganic substances in water through physical adsorption and chemical adsorption. Activated carbon filtration is particularly effective for the removal of chlorine and chloramines.

● Application scenarios: Activated carbon filtration is often used in the front-end steps of hospital water treatment to remove residual chlorine and organic pollutants in tap water, providing purer influent water for subsequent reverse osmosis or deionization treatment. It is also used to remove odors and improve taste in water to ensure the comfort of patients using water.

● Maintenance and management: Activated carbon filter elements need to be replaced regularly because their adsorption capacity decreases with time and usage. The replacement frequency depends on the water quality and usage, and is generally replaced every 3 to 6 months.

Ultraviolet (UV) disinfection system

The UV disinfection system inactivates bacteria, viruses and other microorganisms in water through the bactericidal effect of ultraviolet rays.

● Working principle: The UV disinfection system uses ultraviolet light of a specific wavelength (usually 254 nanometers) to penetrate the cell wall of microorganisms, destroy their DNA or RNA, and prevent them from replicating and surviving. Ultraviolet rays do not change the chemical composition of water and are suitable for use in combination with other filtration systems.

● Application scenarios: UV disinfection is often used in the final treatment stage of water to ensure that the water is sterile before entering the clinical environment or contacting medical equipment. It is usually used in conjunction with reverse osmosis, deionization or ultrafiltration systems to enhance the overall disinfection effect.

● Maintenance and management: UV lamps need to be replaced regularly, usually once a year. At the same time, regular cleaning of the lamp housing and regular monitoring of UV intensity are important measures to maintain the effectiveness of the system.

How to choose a suitable water filtration system?

There are many factors that need to be considered when choosing a suitable water filtration system for hospitals, including water quality requirements, usage scenarios, budgets, and maintenance difficulties. Different clinical scenarios may require different types of water treatment systems. For scenes that require sterility, such as operating rooms and dialysis rooms, reverse osmosis systems and ultraviolet disinfection systems are indispensable. For general clean water, ultrafiltration systems may be sufficient.

Hospital environments require water treatment systems to be highly reliable and easy to maintain. The higher the degree of automation of the equipment, the less need for manual intervention and the lower the operating cost of the system. Hospitals should be equipped with water quality monitoring systems to monitor various water quality indicators in real time to ensure that the water quality always meets medical standards. At the same time, they should have emergency response capabilities to respond quickly and take measures when water quality problems occur.

Although the quality requirements of medical water are high, the initial investment and long-term maintenance costs of the system are also factors that need to be considered. Choose an economical and applicable system while ensuring that stable water quality can be maintained in long-term operation.

Conclusion

The water filtration systems used in hospital clinics cover a variety of technologies such as reverse osmosis, ultrafiltration, deionization, activated carbon filtration, and ultraviolet disinfection. These systems play their respective roles in different application scenarios and work together to ensure the purity and safety of hospital water. By properly configuring and maintaining these water treatment systems, hospitals can effectively ensure the safety of medical processes and the health of patients.