Can reverse osmosis water be used for injection?

Reverse osmosis water is widely used for drinking water, industrial water and medical fields due to its high purity and cleanliness. However, many people have doubts about whether reverse osmosis water can be used for injection.

This article will discuss in detail the characteristics of reverse osmosis water, its scope of application and the scientific basis for its suitability for injection.

What is reverse osmosis water?

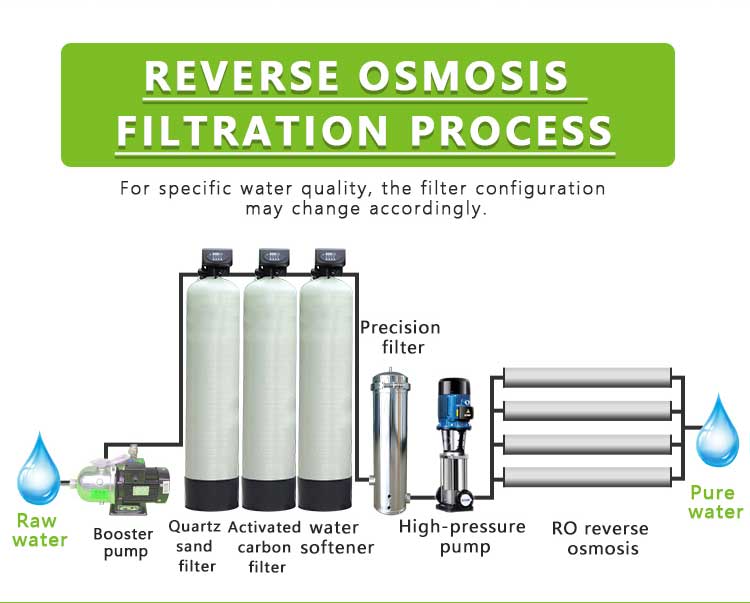

Reverse osmosis is a membrane separation technology that applies pressure to make water molecules pass through a semipermeable membrane, while most dissolved salts, organic matter, bacteria and viruses are blocked on the other side of the membrane. Reverse osmosis water is widely used in household drinking water treatment systems, industrial water production and pharmaceutical industries due to its high purity and good taste.

The main characteristics of reverse osmosis water include:

1. High purity: reverse osmosis water contains almost no dissolved solids and organic matter, and its purity is extremely high.

2. Low mineral content: Since most of the minerals are blocked by the reverse osmosis membrane, the mineral content of reverse osmosis water is extremely low.

3. Sterility: The reverse osmosis membrane can effectively remove bacteria and viruses in water to ensure the sterility of water quality.

What are the applications of reverse osmosis water in the medical field?

The application of reverse osmosis technology in the medical field is mainly concentrated in the pharmaceutical industry and hospital water supply systems. The pharmaceutical industry needs to use high-purity water to produce medicines. Reverse osmosis water has become the first choice for the pharmaceutical industry because of its high purity and strong sterility. However, in the preparation of medical water for injection, reverse osmosis water is only an intermediate step and cannot be used directly for injection.

What are the standards and requirements for water for injection?

According to the provisions of the pharmacopoeias of various countries, water for injection must meet extremely high purity and sterility standards. Taking the Chinese Pharmacopoeia and the United States Pharmacopoeia as examples, water for injection (WFI) needs to meet these three requirements: sterility, purity, and endotoxin content.

1. Sterility: Must pass the sterility test to ensure that there are no bacteria, viruses and other microorganisms.

2. Purity: It needs to be distilled or reverse osmosis plus subsequent treatment to remove all soluble substances and organic matter to ensure that the conductivity of the water is extremely low.

3. Endotoxin content: It must meet the endotoxin standard to prevent the body from causing an immune response.

Can reverse osmosis water be used directly for injection?

Although reverse osmosis water has high purity and sterility, it cannot be used directly for injection. The main reasons include: reverse osmosis water cannot completely guarantee sterility, endotoxin risk, and different purity standards (it may still contain trace impurities).

1. Insufficient sterility guarantee: Although reverse osmosis membrane can remove most bacteria and viruses, it cannot completely guarantee sterility. Water for injection needs to undergo sterility testing and aseptic filling, and reverse osmosis water lacks this guarantee.

2. Endotoxin risk: Reverse osmosis water may contain trace amounts of endotoxins, which are toxins released after the decomposition of bacterial cell walls, and the human body is very sensitive to them. The endotoxin content of water for injection must be strictly controlled, while reverse osmosis water cannot completely ensure this.

3. Different purity standards: The purity requirements of water for injection are extremely high, and all potential soluble substances and organic matter must be removed. Although reverse osmosis water has high purity, it may still contain trace impurities and does not meet the standards for water for injection.

What is the preparation process of water for injection?

The preparation process of water for injection usually includes the following 4 steps: raw water pretreatment → reverse osmosis treatment → distillation or ultra-purification → aseptic filling.

1. Raw water pretreatment: Remove suspended matter, organic matter and hardness in raw water through processes such as sand filtration, activated carbon adsorption and softening.

2. Reverse osmosis treatment: Use reverse osmosis technology to remove most of the soluble solids and organic matter to obtain high-purity reverse osmosis water.

3. Distillation or ultra-purification: Further remove all residual impurities and endotoxins through distillation or ultra-purification technology to ensure the purity and sterility of water.

4. Aseptic filling: Filling in a sterile environment to ensure the sterility of water for injection.

Alternatives and safety assurance

For the preparation of water for injection, reverse osmosis water is only used as an intermediate step and cannot be used directly for injection. In order to ensure the safety and purity of water for injection, pharmaceutical companies usually adopt the following alternatives:

1. Multi-effect distillation: Use a multi-effect distillation device to further purify reverse osmosis water to ensure the purity and sterility of water.

2. Ultrapure water system: Use ultrapure water system for further purification to remove all soluble impurities and organic matter to ensure that the purity of water meets the standards for water for injection.

3. Aseptic filling: Filling is performed under a sterile environment to ensure the sterility and safety of water for injection.

Conclusion on whether reverse osmosis water can be directly used for injection

Reverse osmosis water is widely used in the pharmaceutical industry and medical field due to its high purity and sterility, but it cannot be directly used for injection. Water for injection needs to meet higher purity and sterility standards, must be distilled or ultrapurified, and filled under a sterile environment. Only through strict preparation process and quality control can the safety and purity of water for injection be ensured.