What membranes can be used for reverse osmosis? What are their advantages?

In modern water treatment technology, reverse osmosis (RO) systems have become an important means widely used in drinking water purification, industrial wastewater treatment and seawater desalination due to their high efficiency and reliability. As the core component of the reverse osmosis system, the reverse osmosis membrane determines the performance and efficiency of the system.

So, which membranes can be used for reverse osmosis? What are their advantages? This article will explore these issues in depth and analyze the common types of reverse osmosis membranes and their advantages in detail.

What is the principle of reverse osmosis membranes?

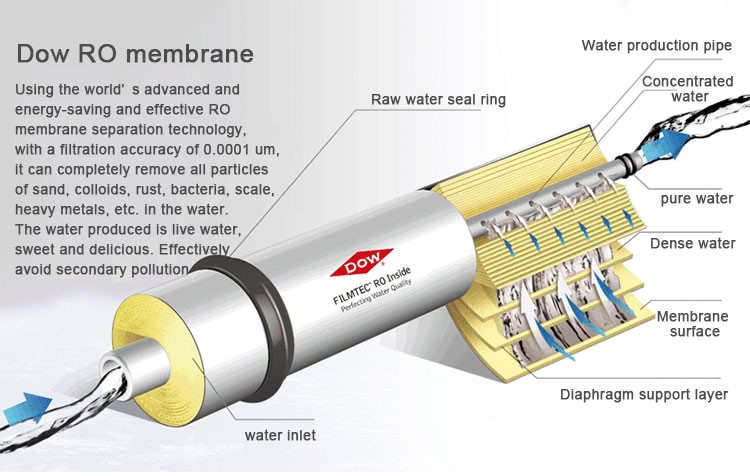

Reverse osmosis membranes are semi-permeable membranes that apply a pressure higher than the osmotic pressure to allow water molecules to pass through the membrane, while most of the impurities such as dissolved salts, microorganisms, and organic matter are retained, thereby achieving water purification and concentration separation. The pore size of the reverse osmosis membrane is extremely small, usually between 0.1 and 1 nanometers, which enables it to effectively retain most pollutants.

How many types of reverse osmosis membranes are there?

Common types of reverse osmosis membranes:

1.1 Cellulose Acetate Membranes,

1.2 Thin-Film Composite Membranes (TFC),

2.1 Spiral-Wound Membranes,

2.2 Hollow Fiber Membranes.

1. Classification by membrane material:

Depending on the membrane material, reverse osmosis membranes are mainly divided into two categories: cellulose membranes and composite membranes.

1.1 Cellulose Acetate Membranes:

Cellulose membranes are mainly made of cellulose acetate and were widely used in reverse osmosis systems in the early days. Cellulose membranes have good chlorine resistance, but poor stability under high temperature and low pH environments.

Advantages of Cellulose Acetate Membranes:

● Good chlorine resistance: Can operate stably in an environment containing chlorine and is not easily oxidized.

● Low cost: The manufacturing cost is relatively low and the economy is good.

1.2 Thin-Film Composite Membranes (TFC):

Composite membranes are composed of multiple layers of thin films, usually including a porous support layer and an ultra-thin high-selectivity separation layer. Composite membranes have high pressure resistance and chemical stability and are widely used in various high-demand water treatment applications.

Advantages of Thin-Film Composite Membranes (TFC):

● High desalination rate: It can efficiently remove dissolved salts and organic matter in water, and the desalination rate can reach more than 99%.

● High pressure resistance: It is suitable for high-pressure operating environment and has high treatment efficiency.

● Good chemical stability: It has good tolerance to a variety of chemical agents and is widely adaptable.

2. Classification by membrane structure:

According to the structure of the membrane, reverse osmosis membranes are mainly divided into two categories: spiral membranes and hollow fiber membranes.

2.1 Spiral-Wound Membranes:

Spiral-Wound Membranes are membrane sheets and spacer layers alternately wound around the central tube to form a compact cylindrical structure. Spiral-Wound Membranes have a high membrane area density and low pressure drop, and are the most commonly used membrane structure in current reverse osmosis systems.

Advantages of Spiral-Wound Membranes:

● Compact structure: small footprint, suitable for large-scale industrial applications.

● High-efficiency filtration: large membrane area and strong processing capacity.

● Easy to replace: modular design, easy installation and maintenance.

2.2 Hollow Fiber Membranes:

Hollow fiber membranes are composed of a large number of hollow fibers, and water is filtered through the inner cavity or outer surface of the hollow fiber. Hollow fiber membranes have a high membrane area and good anti-pollution ability.

Advantages of Hollow Fiber Membranes:

● High membrane area density: large membrane area per unit volume, high processing efficiency.

● Strong anti-pollution ability: the special structure of hollow fibers makes it not easy to clog, suitable for highly polluted environments.

● Low energy consumption: low operating pressure and relatively low energy consumption.

What are the brands of reverse osmosis membranes?

Three major brands of reverse osmosis membranes:

1. Dow reverse osmosis membrane,

2. Hydranautics reverse osmosis membrane,

3. Toray reverse osmosis membrane.

1. Dow reverse osmosis membrane:

FILMTEC® reverse osmosis membrane produced by Dow Chemical Company is known for its high performance and stability and is widely used in various water treatment fields.

Advantages of Dow reverse osmosis membrane:

● High desalination rate: high desalination rate and excellent effluent water quality.

● Long service life: good pressure resistance and chemical stability, long service life.

● Easy maintenance: anti-pollution design, low maintenance cost.

2. Hydranautics reverse osmosis membrane:

Hydranautics is a leading global supplier of membrane separation technology, and its Nitto Hydranautics brand reverse osmosis membrane has excellent performance and reliability.

Advantages of Hydranautics reverse osmosis membrane:

● Excellent anti-pollution ability: special membrane materials and structural design improve anti-pollution ability.

● High flux: provide high water flux while ensuring high desalination rate.

● Wide adaptability: suitable for various complex water quality, stable performance.

3. Toray reverse osmosis membrane:

The reverse osmosis membrane produced by Toray enjoys a high reputation in the market for its high efficiency and durability, and is widely used in seawater desalination and industrial wastewater treatment.

Advantages of Toray reverse osmosis membrane:

● High pressure resistance: suitable for high-pressure operating environment, high treatment efficiency.

● Good stability: good tolerance to various chemical agents and extreme water quality.

● Long service life: high-quality materials and manufacturing processes ensure long-term stable operation.

What are the considerations for selecting reverse osmosis membrane?

When selecting a reverse osmosis membrane, it is necessary to consider a variety of factors to ensure the best treatment effect and economy.

1. Water quality: Different water qualities have different requirements for reverse osmosis membranes. For the treatment of seawater with high salt content, it is necessary to select membranes with high desalination rate and high pressure resistance; while for industrial wastewater treatment, it is necessary to consider the membrane's anti-pollution ability and chemical stability.

2. Treatment scale: The size of the treatment scale directly affects the choice of membrane. Large-scale industrial applications usually require high-flux, compact membranes, while small-scale applications can choose membrane structures with higher flexibility.

3. Operating cost: The operating cost of the reverse osmosis system includes energy consumption, membrane replacement and maintenance costs. Choosing efficient and durable membranes can reduce long-term operating costs and improve economic benefits.

4. Environmental conditions: Environmental conditions such as temperature, pressure, and chemical composition will also affect the selection of reverse osmosis membranes. It is necessary to select membranes that adapt to specific environmental conditions to ensure the stable operation of the system.

Example analysis

Take a large-scale seawater desalination project as an example. The project uses a combination of multiple reverse osmosis membranes to achieve efficient desalination and cost control.

● Phase 1: Use Dow FILMTEC® high desalination reverse osmosis membranes to ensure the initial desalination effect.

● Phase II: Combined use of Nitto Hydranautics anti-fouling membranes to improve system stability and durability.

● Phase III: Adopting Toray high-pressure membranes to cope with high-pressure operating environments and ensure long-term operation.

The successful implementation of this project fully demonstrates the importance of rational selection and combination of reverse osmosis membranes.

Conclusion on the types of reverse osmosis membranes

Reverse osmosis membranes are the core components of reverse osmosis systems. Different types of reverse osmosis membranes have their own advantages and disadvantages in materials, structures and performance. Cellulose membranes and composite membranes have their own advantages in material selection, while spiral membranes and hollow fiber membranes have their own characteristics in structural design. Reverse osmosis membranes from brands such as Dow, Hydranautics and Toray are widely used in various water treatment fields due to their excellent performance and stability.

Selecting the right reverse osmosis membrane, taking into account water quality, treatment scale, operating costs and environmental conditions, is the key to achieving efficient water treatment.