How to make a reverse osmosis membrane? What is its manufacturing cost?

As a core component of modern water treatment technology, reverse osmosis membrane is widely used in seawater desalination, wastewater treatment and household water purification. Reverse osmosis membrane can effectively remove dissolved salts, organic matter, microorganisms and particulate matter in water to provide high-quality pure water.

So, how is this efficient filter material made? What is its manufacturing cost? This article will explore the manufacturing process of reverse osmosis membrane and its cost structure in depth.

Basic principles and applications of reverse osmosis membrane

1.1 Basic principles of reverse osmosis membrane

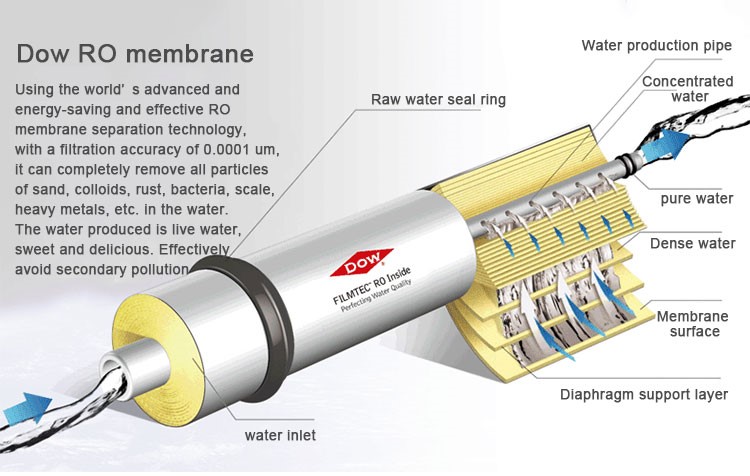

Reverse osmosis (RO) is a technology that uses a pressure-driven physical process to remove dissolved salts and impurities from water through a semipermeable membrane. The reverse osmosis membrane has a nanoscale pore size, and water molecules can enter the water production side through the membrane pores, while dissolved salts, microorganisms and organic matter are retained on the concentrated water side.

1.2 Application of reverse osmosis membrane

Reverse osmosis membrane is widely used in many fields, including:

● Desalination: remove salt from seawater to produce drinkable fresh water.

● Wastewater treatment: remove pollutants from industrial wastewater and realize water resource recycling.

● Home water purification: provide high-quality drinking water and remove impurities and pollutants from tap water.

Manufacturing process of reverse osmosis membrane

2.1 Preparation materials

The main material of reverse osmosis membrane is polyamide (PA), which has excellent chemical stability and mechanical strength and is suitable for the preparation of efficient separation membranes. The support layer of the membrane usually uses polyester (Polyester) or polypropylene (Polypropylene) materials to increase the strength and durability of the membrane.

2.2 Preparation process

The preparation process of reverse osmosis membrane includes the following key steps:

● Pretreatment

Before preparing the reverse osmosis membrane, the polyamide raw material needs to be pretreated to remove impurities and insolubles. Common methods include filtration and refining to ensure the purity and uniformity of the raw materials.

● Coating and impregnation

The pre-treated polyamide solution is evenly coated on the support layer material, and then the coated material is immersed in water or an organic solvent to form a thin film of the polyamide solution on the surface of the support layer. The solvent volatilization and phase separation during the impregnation process make the polyamide form a semipermeable membrane with nano-scale pores.

● Post-treatment

After the membrane is formed, a series of post-treatment steps are required, including cleaning, heat treatment and cross-linking. The cleaning process can remove residual solvents and impurities on the membrane surface; heat treatment can improve the mechanical strength and thermal stability of the membrane; cross-linking treatment can enhance the chemical stability and anti-fouling ability of the membrane.

● Membrane element assembly

The prepared reverse osmosis membrane is cut into the required size and assembled into a membrane element with other components such as a central tube, a support mesh and a sealing ring. The membrane element is the core component in the reverse osmosis system and usually exists in a roll or tubular structure.

What is the manufacturing cost of the reverse osmosis membrane?

3.1 Material cost

The main material costs of the reverse osmosis membrane include polyamide, support layer materials (such as polyester or polypropylene) and various chemical reagents. According to market prices, the price of polyamide is approximately between US$20 and US$50 per kilogram, and the price of support layer materials is between US$5 and US$10 per square meter. The cost of chemical reagents varies depending on the type and amount used.

3.2 Equipment and Energy Costs

The manufacture of reverse osmosis membranes requires specialized equipment and facilities, including coating machines, immersion tanks, cleaning equipment, and heat treatment furnaces. The investment cost of these equipment is high, and the energy consumption in the manufacturing process cannot be ignored. Depending on the production scale and equipment configuration, the proportion of equipment and energy costs is approximately between 20% and 30% of the total cost.

3.3 Labor Costs

The manufacture of reverse osmosis membranes requires professional technicians to operate and manage, so labor costs are also an important component. The labor cost in the manufacturing process varies depending on the region and factory size, and generally accounts for 10% to 20% of the total cost.

3.4 Maintenance and Management Costs

The daily maintenance of equipment and the operation and management of the factory also require certain costs, which include equipment maintenance, replacement of consumables, and daily management expenses of the factory. Depending on the operation of different factories, maintenance and management costs account for 5% to 10% of the total cost.

3.5 Total Cost Analysis

Taking the above factors into consideration, the manufacturing cost of reverse osmosis membranes includes material costs, equipment and energy costs, labor costs, and maintenance and management costs. Taking the manufacturing of one square meter of reverse osmosis membrane as an example, the total cost is approximately between US$20 and US$50. The actual cost fluctuates due to differences in production scale, process technology and market price.

How to reduce the manufacturing cost of reverse osmosis membrane?

4.1 Technological innovation

Through technological innovation, the performance of membrane materials and the efficiency of manufacturing processes can be improved, which can effectively reduce the manufacturing cost of reverse osmosis membranes. For example, developing new polyamide materials or improving coating and impregnation processes can help improve membrane performance and production efficiency.

4.2 Large-scale production

Large-scale production can dilute equipment and energy costs, while improving production efficiency and reducing the manufacturing cost of a single product. Establishing a large-scale reverse osmosis membrane production base will help reduce overall production costs.

4.3 Automation and intelligence

Introducing automated and intelligent production equipment can reduce labor costs and improve production efficiency. Through the application of automated equipment, precise control and efficient management of the production process can be achieved, further reducing manufacturing costs.

4.4 Resource optimization and recycling

In the production process, through resource optimization and recycling, reduce the waste of raw materials and energy. For example, recycling and reusing cleaning wastewater and heat treatment waste heat can effectively reduce production costs.

Conclusion

As a core component of efficient water treatment, the manufacturing process of reverse osmosis membrane is complex and the cost is high. However, through technological innovation, large-scale production, automation and intelligent management, as well as resource optimization and recycling, the manufacturing cost of reverse osmosis membrane can be effectively reduced.