How Much Does it Cost to Build a Large Reverse Osmosis Water Treatment Plant?

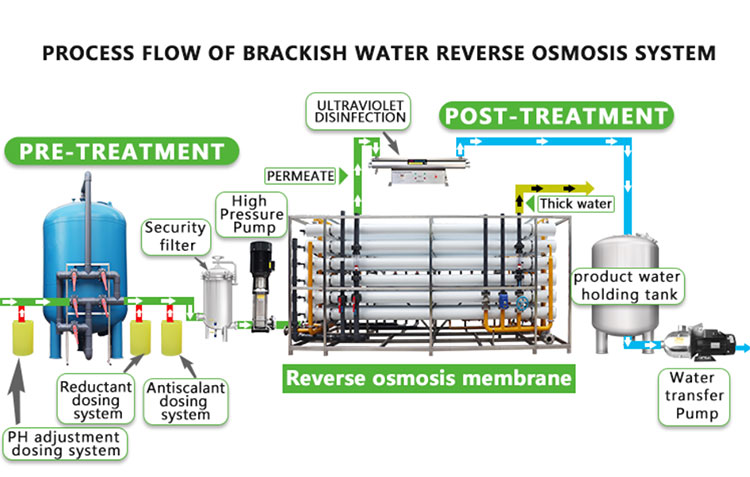

Reverse osmosis water treatment plants use membrane technology to separate salt and impurities from water to provide clean fresh water resources. However, building a large reverse osmosis water treatment plant involves complex engineering design, high equipment procurement and operation and maintenance costs.

This article will explore in detail the various costs of building a large reverse osmosis water treatment plant and list the construction cost analysis of several famous water treatment plants in the world.

What is the purpose of building a reverse osmosis water treatment plant?

The purpose of building a reverse osmosis water treatment plant is to be used in fields such as seawater desalination, wastewater treatment and groundwater purification. Its core technology is the reverse osmosis membrane, which applies pressure to force water molecules through the semi-permeable membrane, retaining dissolved salts and other impurities on the other side of the membrane. Large reverse osmosis water treatment plants generally have a high processing capacity and can process tens of thousands to hundreds of thousands of cubic meters of water per day.

How much does it cost to build a large reverse osmosis water treatment plant?

The cost of building a large reverse osmosis water treatment plant mainly includes the following aspects:

1. Preliminary research and design:

● Preliminary research: Before the project starts, a comprehensive water quality survey, geological survey and environmental impact assessment are required. These survey data will provide an important basis for engineering design. The cost of preliminary research is usually 5% to 10% of the total project cost.

● Engineering design: including overall planning, process design, equipment selection and construction drawings. The cost of engineering design generally accounts for 5% to 8% of the total cost.

Overall, the cost of preliminary research and design is about 10% to 18% of the total project cost.

2. Civil engineering:

Civil engineering includes plant construction, infrastructure construction, pipeline laying, etc. This part of the cost varies depending on the scale and geographical location of the project.

● Plant construction: The plant includes raw water treatment workshop, reverse osmosis membrane workshop, chemical agent workshop and control room. The construction cost is generally US$150 to US$450 per square meter.

● Infrastructure construction: including inlet and outlet pipes, sludge treatment facilities, water storage tanks, etc. The cost varies from place to place, generally accounting for 10% to 20% of the total cost.

The total cost of civil engineering accounts for about 20% to 30% of the total project cost.

3. Equipment procurement:

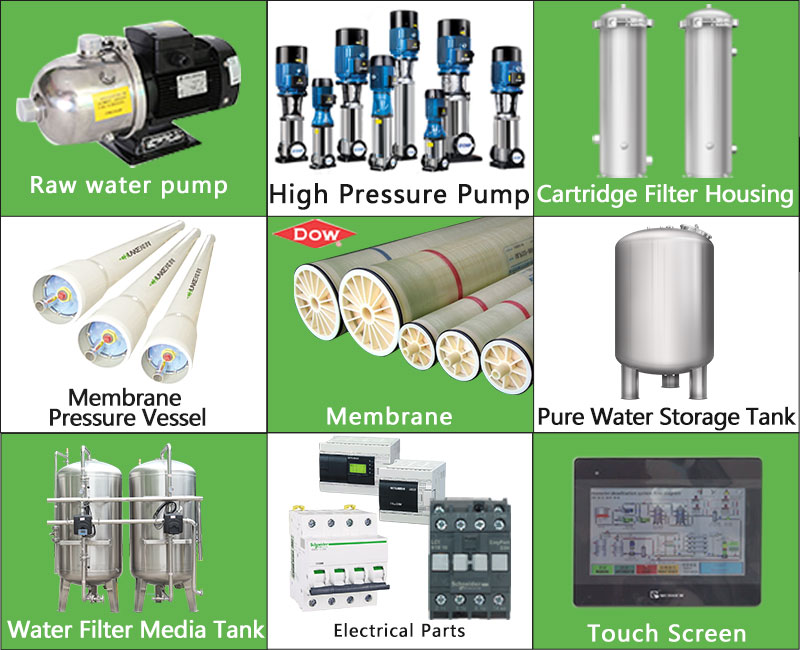

The core equipment of the reverse osmosis water treatment plant includes reverse osmosis membrane components, high-pressure pumps, pretreatment systems, post-treatment systems and control systems.

● Reverse osmosis membrane components: It is the core of the entire system. The quality and performance directly affect the water output effect and operating costs. The price of each set of reverse osmosis membrane components ranges from US$500 to US$10,000.

● High-pressure pump: It is used to provide the high pressure required for reverse osmosis. The price depends on the brand and specifications, generally between US$100,000 and US$500,000.

● Pretreatment system: Including sand filtration, activated carbon filtration, etc., used to remove suspended matter and organic matter in raw water and extend the life of reverse osmosis membranes. The price of the pretreatment system is 5% to 10% of the total cost.

● Post-treatment system: Including ultraviolet disinfection, ozone disinfection, etc., used to ensure that the effluent water quality meets the drinking water standards.

● Control system: The higher the degree of automation, the higher the cost, generally accounting for 5% to 8% of the total cost.

The total cost of equipment procurement accounts for about 40% to 50% of the total project cost.

4. Installation and commissioning:

Equipment installation and system commissioning are important links to ensure the normal operation of the water treatment plant. Installation costs include equipment installation, pipeline connection, electrical engineering and automation control system commissioning. Commissioning costs include system commissioning, trial operation and performance testing.

Installation and commissioning costs generally account for 10% to 15% of the total cost.

5. Operating costs:

In addition to construction costs, the operating costs of reverse osmosis water treatment plants also need to be considered, including electricity costs, chemical costs, equipment maintenance costs and labor costs.

● Electricity costs: The reverse osmosis system consumes a lot of electricity, and electricity costs are an important part of the operating costs.

● Chemical costs: Chemicals used for pretreatment and post-treatment, including flocculants, bactericides, etc.

● Equipment maintenance costs: Regularly replace the wearing parts of reverse osmosis membranes and high-pressure pumps to ensure long-term and stable operation of the system.

● Labor costs: Including the wages of operators and technicians.

The operating cost is generally $0.5 to $1 per ton of water treatment cost.

Case Study on the Construction of Reverse Osmosis Water Treatment Plant

The following is an analysis of the construction costs of several famous water treatment plants in the world:

1. Sorek Desalination Plant in Israel:

The Sorek Desalination Plant is one of the largest reverse osmosis desalination plants in the world, located in the south of Tel Aviv, Israel.

● Processing capacity: 150 million cubic meters per year

● Construction cost: approximately $400 million

● Operating cost: approximately $0.58 per cubic meter of water treatment cost

2. Carlsbad Desalination Plant in the United States:

The Carlsbad Desalination Plant is the largest desalination plant in the United States, located in San Diego County, California.

● Processing capacity: 189,000 cubic meters per day

● Construction cost: about $1 billion

● Operating cost: about $0.79 per cubic meter of water treatment

3. Ras Al Desalination Plant in Saudi Arabia:

The Ras Al Desalination Plant is located in Saudi Arabia and is the world's largest multi-stage flash evaporation and reverse osmosis desalination plant.

● Processing capacity: 1,000,000 cubic meters per day

● Construction cost: about $7.3 billion

● Operating cost: about $0.5 per cubic meter of water treatment

Summary of the cost of building a large reverse osmosis water treatment plant

Based on the above analysis, the cost of building a large reverse osmosis water treatment plant varies depending on the geographical location, treatment scale and technical requirements. Taking the Sorek Desalination Plant as an example, the initial construction cost was about $400 million, while the construction cost of the Carlsbad Desalination Plant was as high as $1 billion. As the world's largest desalination plant, the construction cost of the Ras Al Desalination Plant is as high as $7.3 billion.

Although reverse osmosis water treatment plants are expensive to build, their importance in solving the global water shortage problem is self-evident. By using advanced reverse osmosis technology, these water treatment plants can effectively provide clean and safe fresh water resources to ensure people's living and production needs.