How often should you flush your reverse osmosis system?

Reverse osmosis system is a common equipment in the field of water treatment. It can effectively remove impurities and pollutants in water and provide clean drinking water.

However, over time, reverse osmosis systems can become contaminated and clogged to a certain extent, requiring regular cleaning and maintenance. So, how often should you flush your reverse osmosis system? Does the RO system require maintenance? Let's analyze this problem below.

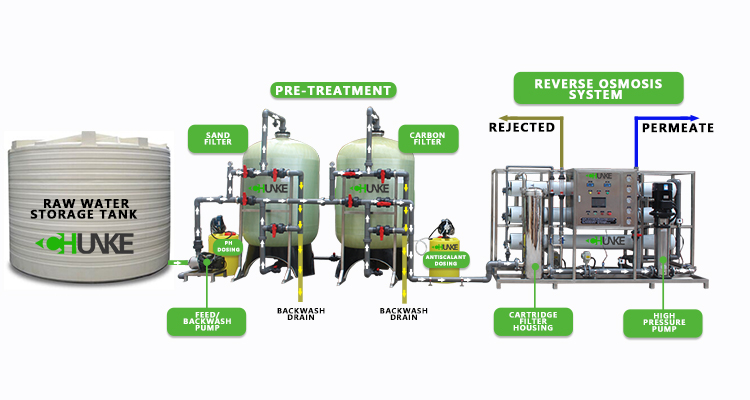

Learn how reverse osmosis systems work

First, we need to understand how a reverse osmosis system works. Reverse osmosis systems use semi-permeable membranes to filter impurities and salts from water, thereby purifying the water. However, after a period of use, the semipermeable membrane may become clogged with pollutants, affecting the purification effect and water quality of the system.

The importance of regular cleaning of reverse osmosis systems

Due to the working principle of the RO system, regular cleaning is key to ensuring the normal operation of the system. As a general rule of thumb, it is recommended to clean your reverse osmosis system every 3 to 12 months. This can effectively remove pollutants and impurities, restore the purification effect of the system, and ensure the safety and stability of water quality.

The necessity of RO system maintenance

At the same time, the RO system requires frequent maintenance to ensure its long-term stable operation. Every reverse osmosis system requires frequent cleaning in place (CIP) to remove clogged contaminants and impurities. However, the frequency of maintenance will depend on many factors, including water chemistry and desired recovery rates.

What is the flushing process of the RO system?

The flushing process of the RO system removes dirt and impurities through chemical cleaning and physical cleaning, and restores the filtration effect and water production rate of the membrane module. The correct flushing process can ensure the stable operation and long-term use of the system and provide high-quality drinking water resources.

Chemical cleaning involves adding an appropriate amount of chemicals to dissolve and remove dirt and impurities, such as sodium bicarbonate, nitric acid, or hydrogen peroxide. These chemicals can effectively break down dirt and bacteria, clean the surface of the membrane module, and restore its filtration effect and water production rate. Physical cleaning uses circulating water flow and mechanical force to flush and clean the membrane module surface. High-pressure water flow and mechanical brushing are usually used to wash away dirt and impurities from the membrane surface to keep the membrane components clean and permeable. Physical cleaning usually needs to be combined with chemical cleaning to achieve the best cleaning effect.

How to perform regular maintenance of RO system?

Regular maintenance of the RO system includes regular inspection and cleaning of various components of the RO system. This includes checking the operating status and working efficiency of core components such as filters, membrane modules, and pumps, and promptly replacing and cleaning damaged or contaminated components to ensure the normal operation of the system. At the same time, it is also necessary to regularly check the pressure, flow, water quality and other parameters of the system to discover and solve potential problems and avoid system failures.

Secondly, regular maintenance also includes regular cleaning and disinfection of the RO system. As mentioned previously, system cleaning is recommended every 3 to 12 months to remove dirt and impurities and restore the system's filtration effectiveness and water production rate. In addition, the system needs to be disinfected regularly to kill bacteria and viruses and ensure the safety and hygiene of water quality.

Finally, regular maintenance also includes monitoring and adjusting operating parameters of the RO system. By monitoring the pressure, flow, water quality and other parameters of the system, operational problems can be discovered and solved in a timely manner to ensure the stable operation of the system. At the same time, the operating parameters and working mode of the system can also be adjusted according to the actual operating conditions and needs to improve the efficiency and performance of the system. Scientific and reasonable regular maintenance can ensure the stable operation and long-term use of the RO system, provide people with high-quality drinking water resources, and protect people's health and safety.

What are the steps and precautions for cleaning a RO system?

Reverse osmosis system cleaning steps

First, let us understand the steps for reverse osmosis system cleaning. Cleaning the RO system usually involves the following steps: First, close the water inlet valve and drain the remaining water. Then, open the pressure reducing valve to release the pressure inside the system. Next, use the appropriate cleaning agents and tools to clean the reverse osmosis system according to the manufacturer's instructions. Finally, after cleaning, close the pressure reducing valve and reopen the water inlet valve to restore normal operation of the system.

Precautions for cleaning the RO system

In addition, there are some things you need to pay attention to when cleaning the reverse osmosis system. First, make sure you use the proper cleaning agents and tools during the cleaning process to avoid damage to your system. Secondly, during the cleaning process, pay attention to protecting key components of the system, such as pumps, membranes, etc., to prevent accidental damage. Finally, after cleaning, be sure to flush the system thoroughly to ensure that the cleaning agent and residues are completely removed and do not affect the operation of the system and the purification effect of water quality.

How to tell when a reverse osmosis system needs cleaning?

Observe changes in water quality

First of all, observing changes in water quality is one of the important indicators to judge whether the reverse osmosis system needs cleaning. If the water quality deteriorates significantly, with odor, turbidity, etc., the system may be blocked by pollutants and needs to be cleaned.

Check the working status of the system

Secondly, checking the working status of the system can also help determine whether the reverse osmosis system needs cleaning. If the water production of the system drops significantly and the proportion of wastewater increases, there may be a problem with the system and it needs cleaning and maintenance.

Regularly check system performance

Finally, regular inspection of system performance is also one of the important measures to ensure the normal operation of the reverse osmosis system. Regularly checking the system's indicator parameters, such as water production, wastewater ratio, water quality, etc., can promptly detect system problems and avoid water quality degradation and equipment damage.