What is the processing capacity of 1000 LPH reverse osmosis plant?

When we talk about 1000 LPH (1000 liters per hour) reverse osmosis plant, the first thing we focus on is its processing capacity and the chemicals used. Let’s take a closer look at these issues.

1000 LPH reverse osmosis plant processing capacity

A 1000 LPH reverse osmosis plant can purify 1000 liters of water per hour. This means that under continuous operation, the device can process 1,000 liters of water, remove impurities and dissolved substances in the water, and produce pure water that meets standards. There are various types of 1000 LPH reverse osmosis plants on the market, ranging from semi-automatic to fully automatic, so when choosing a device you need to make a suitable choice based on your actual needs and budget. After reverse osmosis treatment, the TDS (total dissolved solids) of the water will be greatly reduced, usually less than 100 parts per million (PPM), ensuring high purity of water quality.

What chemicals are used in reverse osmosis plant?

In the reverse osmosis (RO) process, some chemicals are usually required to control the water quality and the operation of the unit. The main chemicals used include acids and antiscalants. Acid is mainly used to control calcium carbonate scaling, while antiscalants are used to prevent membrane surface scaling. In order to overcome the pH buffering capacity of natural water, it is usually necessary to use a large amount of concentrated sulfuric acid or hydrochloric acid to reduce the Langelier saturation index of the RO concentrate. When used correctly, these chemicals can effectively protect the reverse osmosis membrane and extend the life of the device while maintaining the quality of pure water.

How does RO plant ensure water purification effect?

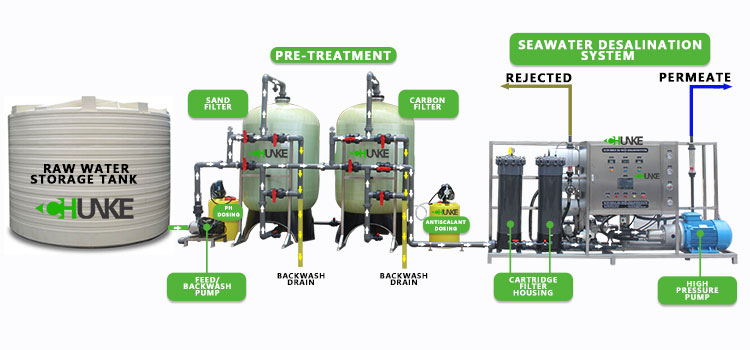

RO plant ensures the purification effect of water quality through efficient filtration and interception mechanisms, high-quality membrane materials and pre-treatment systems, providing people with a safe and healthy water environment. In the RO process, water passes through a semipermeable membrane, and only water molecules can pass through, while most dissolved substances and microorganisms are filtered out. This allows the RO plant to effectively remove impurities and pollutants from the water, making the water quality up to drinking or industrial water standards.

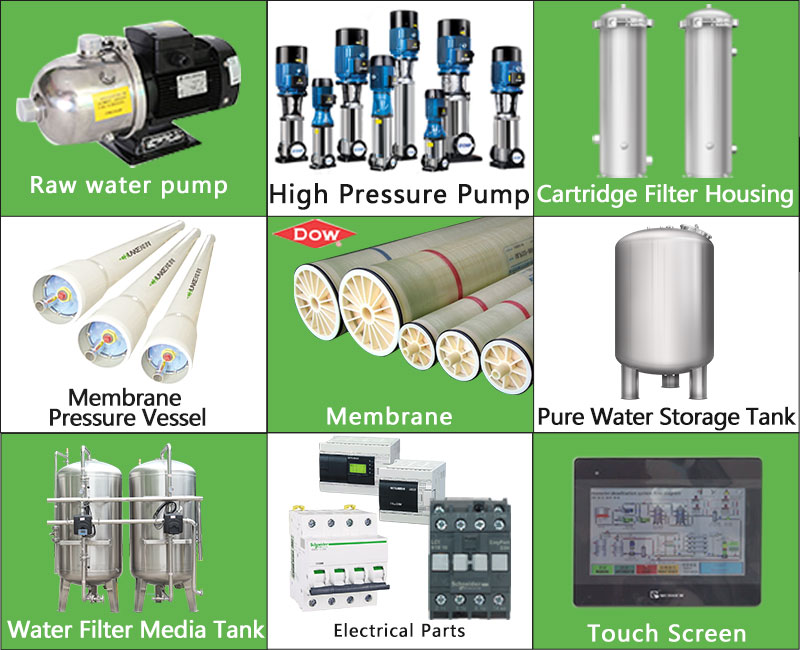

The RO plant uses a high-pressure pump to push water through a semipermeable membrane, allowing water molecules to pass through, while most dissolved substances and microorganisms are trapped on the membrane surface. This substance separation mechanism ensures the purification effect of water quality. RO plant's membrane components are manufactured using advanced materials and processes and have excellent filtration and retention performance. The membrane surface has been specially treated to effectively prevent pollution and scaling and maintain membrane permeability and stability. RO plants are usually equipped with pretreatment systems, such as particle filters, activated carbon filters, etc., which are used to remove suspended solids, organic matter, chlorine and other substances in the water, protect the reverse osmosis membrane components from damage and contamination, and further improve the water purification effect.

What are the key points for selecting a 1000 LPH reverse osmosis plant?

1. Device type and degree of automation

When selecting a 1000 LPH reverse osmosis plant, the first thing to consider is the type of unit and degree of automation. There are many types of devices on the market, both semi-automatic and fully automatic. According to actual needs and budget, select the appropriate device type to ensure that it can meet daily production or domestic water needs.

2. Water quality requirements and TDS control

Secondly, water quality requirements and TDS control need to be considered. According to the industry and purpose, determine the required water quality standards and TDS control range, and select the appropriate configuration and supporting equipment of the device to ensure that the quality of the produced water meets the requirements.

3. Chemical usage and cost considerations

Finally, there are chemical usage and cost considerations to consider. When selecting a device, it is necessary to evaluate the amount of chemicals used and the cost, and comprehensively consider the operating and maintenance costs of the device to select products with higher cost performance.

What precautions should be taken in the operation and maintenance of RO plant?

1. Regular cleaning and maintenance

The operation and maintenance of RO plant are very important, which can effectively extend the service life of the device and ensure the stability of water quality. Clean and maintain the device regularly to remove dirt that may clog pipes and membrane surfaces to ensure normal operation of the device.

2. Control the dosage of chemicals

In the process of using chemicals, the dosage needs to be strictly controlled to avoid excessive use that may cause damage to the device or a decrease in the quality of the produced water. At the same time, storage conditions of chemicals should be regularly checked to ensure their quality and effectiveness.

3. Regularly test water quality

Regularly conduct water quality testing on the produced water, monitor changes in water quality and the operating status of the device, promptly discover and solve possible problems, and ensure that the quality of the produced water is stable and meets requirements.

1000 LPH reverse osmosis plant is a type of water treatment equipment. Its processing capacity and chemical usage are the focus of users. Selecting the appropriate device type and configuration, using chemicals correctly, and performing regular maintenance and testing are all keys to ensuring proper operation of the device and stable water quality.