RO Water Purifier with High Quality and Affordable Price from China

What is best RO Water Purifier: Everything You Need to Know

Reverse osmosis or ro water purifier is a demineralization process that relies on a semipermeable membrane to effect the separation of dissolved solids from a liquid. The semipermeable membrane allows liquid and some ions to pass, but retains the bulk of the dissolved solids (ions). To understand how RO works, it is first necessary to understand the natural process of osmosis.

Behind of the Science: Best RO Water Purifier Here

Reverse osmosis or ro water purifier is a demineralization process that relies on a semipermeable membrane to effect the separation of dissolved solids from a liquid. The semipermeable membrane allows liquid and some ions to pass, but retains the bulk of the dissolved solids (ions). To understand how RO works, it is first necessary to understand the natural process of osmosis.

Osmosis is a natural process where water flows through a semipermeable membrane from a solution with a low concentration of dissolved solids to a solution with a high concentration of dissolved solids.

Reverse osmosis is the process by which an applied pressure, greater than the osmotic pressure, is exerted on the compartment that once contained the high-concentration solution. Th is pressure forces water to pass through the membrane in the direction reverse to that of osmosis.

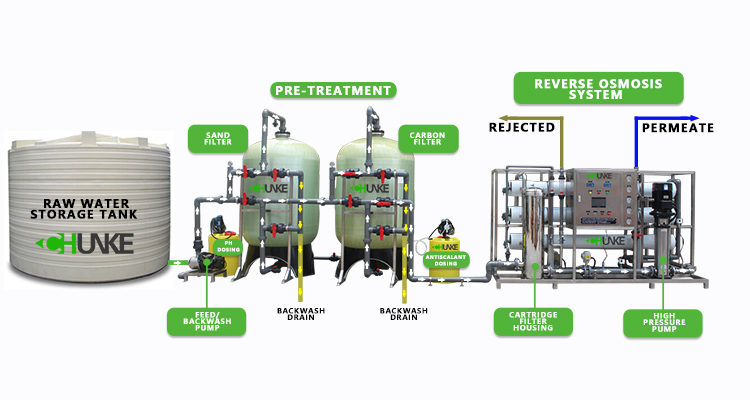

Chunke RO water purifier process includes raw water storage tank, booster pump, sand filter, activated carbon filter, softener, cartridge filter housing with pp filter or bag filter housing with bag filter, high pressure pump, reverse osmosis membrane, flow meters, pressure gauges, uv sterilization, ozone generator, stainless steel pure water storage tank.

Now we explain here how does ro water purifier work? First of all, we pump dirty water from raw water storage tank to pretreatment by booster pump. In Chunke most of project we are using 3 brands depend on customer budget : Grundfos, CNP and NYP.

Depends on water analysis report, we can use sand filter, activated carbon filter and softener. In Chunke, for this filters, we are using three different materials, stainless steel 304 / 316, carbon steel and FRP (Fiber-reinforced plastic) for filter tanks. Water first passes sand filter, sand filter can remove bigger particles, then passes activated carbon filter, it helps to remove odor, color, chlorine and some organic compounds in water, if water has hardness problem, after mechanical filter we use softener and water passes softener tank. Softener tank inside there is ion exchange resin, ion exchange resin help us to replace Ca ions with Na ions, which makes water softer.

After pretreatment tanks, water passes cartridge filter housing or bag filter housing. Cartridge filter housing has PP filter, this PP filter pores size is in different range, we are mostly use 1micrometer and 5 micrometer size during industrial applications. Some projects depends on flow rate and water quality, we are using bag filter housing with 1 micrometer or 5 micrometer bag filter. We called cartridge filter as security filter, because we want to be sure, any big particle does not go to membrane surface.

After cartridge filter housing, reverse osmosis membrane filtration process starts RO membranes are in membrane housing so we are using FRP or Stainless Steel membrane housing for most of project. Commercial ro water purifiers are using 4040, on the other hand industrial reverse osmosis water purification systems are using 8040 membranes. In Chunke, most of projects we are using Dow Filmtec, Toray, Hydranautics, LG, Vontron membranes.

Here we explain how does ro water purifer membrane work?

Reverse osmosis membranes are constructed from a membrane flat sheet so it is comprised of three layers:

a) Polyester fabric support base

b) Micro porous polysulfone layer

c) 0.2 micrometer polyamide barrier layer

The polysulfone layr strengthens the very thin barrier layer, it allows water to pass through while preventing other compounds from passing through membranes remove molecules based on their size shape and charge, generally contaminants larger than water molecules will not pass through including most chemical contaminants and all microorganisms such as viruses and bacteria .

The membrane flat sheet is combined with a sheet of feed channel spacer ,this provides turbulence and creates space between the membrane sheets for the feed water, a sheet of permeate spacer is added to the membrane sheets and finally feed channel spacer, this enables the final recycled water product or permeate to flow evenly across the entire membrane surface even under high pressure, the back of the membrane is completely sealed to the edges of the permeate spacer, the membrane sheets are glued along each of the three exposed sides and rolled around the core tube, feedwater is forced through the feed channel spacer and into the barrier layer of the membrane, water passes through the membrane surface into the permeate channel, it flows in a spiral direction and collects in the core tube ,this water is the final recycled water product or permeate.

Here we called a phrase as “permeate”, it means that pure, clean water. Every ro water purifier system has waste water called as concentrate. RO concentrate includes elevated concentrations of contaminants that are removed during treatment of water for pure, clean water use.

If you need your system for drinking water, click here to reach World Health Organization Drinking Water Standards. Also you can get commercial knowledge about ro water purifier from here.

If you have any question about ro water purifier system, reverse osmosis water purification plant, please visit us add our Whatsapp: +86 166 16636489