What is ultrafiltration for drinking water? Is it a form of reverse osmosis?

The safety and quality of drinking water have always been a global concern. With the advancement of science and technology, more and more water treatment technologies are being used to purify drinking water. Among these technologies, ultrafiltration (UF) treatment is an important method that is widely used in household, community and industrial water treatment systems.

So, what is ultrafiltration for drinking water? Is it part of reverse osmosis (RO) technology? This article will explore these issues in detail to help readers better understand the principles, applications and differences between ultrafiltration and reverse osmosis.

What is ultrafiltration?

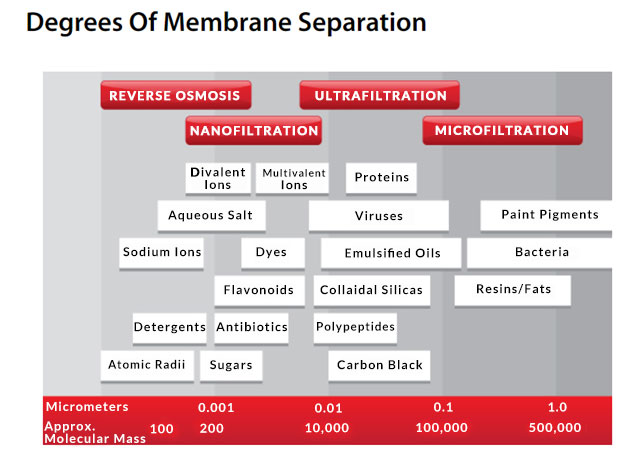

Ultrafiltration is a water treatment method based on membrane separation technology. Its core is to use ultrafiltration membranes to remove pollutants such as suspended matter, bacteria, viruses and some organic matter in water through physical screening. The pore size of ultrafiltration membranes is generally between 0.01 and 0.1 microns, which enables it to effectively block the passage of larger particles and microorganisms while allowing water molecules and some dissolved substances (such as inorganic salts) to pass smoothly.

Ultrafiltration membranes are usually made of polymer materials and have a microscopic pore structure. The size of these holes determines the accuracy of the ultrafiltration treatment. Typically, the pore size of the ultrafiltration membrane ranges from 0.01 to 0.1 microns, which means it can remove pollutants with a diameter greater than 0.01 microns. Compared with other membrane filtration technologies, ultrafiltration membranes have a higher filtration accuracy and can remove a variety of pollutants including bacteria, viruses and suspended particles.

The filtration process of the ultrafiltration membrane mainly relies on the pressure difference. When water passes through the membrane surface, larger pollutant particles are retained on the membrane surface, while smaller water molecules pass through the membrane pores and enter the next treatment stage or are directly used as purified water.

What is the principle of ultrafiltration treatment?

The principle of ultrafiltration treatment is relatively simple: water passes through the ultrafiltration membrane under pressure, and substances with larger membrane pores (such as suspended particles, bacteria, viruses, etc.) are retained on the membrane surface, while smaller water molecules and soluble substances pass through the membrane to the clean water end. This process does not involve chemical reactions, but is based on the principle of physical separation. Therefore, ultrafiltration treatment does not change the chemical composition of water, but only removes suspended matter and microorganisms in the water.

What are the advantages of ultrafiltration treatment?

The pore size of the ultrafiltration membrane is small enough to effectively remove bacteria and viruses from the water, which makes ultrafiltration an important means of ensuring the microbial safety of drinking water. Especially in areas with poor water quality, ultrafiltration can significantly reduce the content of pathogenic microorganisms in drinking water and ensure water quality.

Compared with reverse osmosis technology, ultrafiltration does not remove dissolved minerals and inorganic salts in water, which means that beneficial minerals in water are retained. This makes ultrafiltration an ideal choice for those who want to retain a certain amount of minerals in drinking water.

In addition, ultrafiltration is a technology based on physical separation, and the whole process does not involve chemical reactions, so no chemical agents are required. Compared with some water treatment methods that require the addition of disinfectants, ultrafiltration is more environmentally friendly and does not introduce chemical pollutants. Ultrafiltration membranes also generally have a long service life, and their maintenance and cleaning are relatively simple. Compared with other water treatment technologies, the operation and maintenance costs of ultrafiltration systems are relatively low, making them particularly suitable for use in homes and small communities.

Ultrafiltration vs. reverse osmosis, what is the difference?

The pore size of the reverse osmosis membrane is usually around 0.0001 microns, which allows it to remove almost all soluble salts, organic matter, metal ions and other soluble contaminants. The pore size of the ultrafiltration membrane is larger, about 0.01 to 0.1 microns, and is mainly used to remove larger suspended solids, bacteria and viruses. Therefore, the water quality treated by reverse osmosis is usually purer, but it also removes beneficial minerals in the water.

Ultrafiltration treatment is a physical screening process that mainly relies on the pore size of the membrane to filter out pollutants, while reverse osmosis is a more complex process that uses a semipermeable membrane to separate water from soluble pollutants under pressure. Reverse osmosis requires higher operating pressures and produces a certain proportion of wastewater during the filtration process.

Ultrafiltration treatment is usually used for household drinking water filtration, pretreatment stages, and scenarios where minerals need to be retained in water due to its retention of minerals in water and lower operating pressure. Reverse osmosis systems are more suitable for occasions that require highly pure water, such as laboratory water, the pharmaceutical industry, and process water with extremely high water quality requirements.

What are the application areas of ultrafiltration treatment?

Ultrafiltration technology is widely used in many fields due to its significant advantages, especially in drinking water treatment, food and beverage production, industrial water treatment and other fields.

In household and community drinking water treatment systems, ultrafiltration is often used as a key step to ensure the removal of suspended matter and microorganisms in water. The ultrafiltration treatment system can effectively improve the quality of tap water, making it more suitable for direct drinking.

In the process of industrial water treatment, ultrafiltration is used to remove suspended particles and organic matter in water to protect downstream equipment from pollution. At the same time, ultrafiltration is also used in some industrial production processes that have high requirements for water quality, such as food and beverage production, to remove microorganisms and suspended matter in raw water.

In the food and beverage industry, water quality directly affects the quality of products. Ultrafiltration technology can effectively remove bacteria and viruses in water to ensure the safety of production water. At the same time, ultrafiltration can also retain necessary minerals in water to ensure the taste and quality of products.

Composition and operation of ultrafiltration treatment system

A complete ultrafiltration treatment system usually consists of multiple components, including pretreatment devices, ultrafiltration membrane components, pump systems and control systems. These components work together to ensure the efficient operation of the ultrafiltration treatment system and the stability of water quality.

In the ultrafiltration treatment system, the pretreatment device is used to remove large particles and suspended matter in the water, reduce the load on the ultrafiltration membrane, and extend the service life of the membrane. Pretreatment usually includes equipment such as sand filters and activated carbon filters to ensure that the water entering the ultrafiltration membrane is relatively clean.

The ultrafiltration membrane assembly is the core part of the entire system and determines the filtration accuracy and quality of the water. The ultrafiltration membrane usually exists in the form of hollow fibers or flat plates. Water passes through the membrane under pressure, and suspended matter and microorganisms are trapped on the membrane surface.

The pump system provides the necessary water pressure for the ultrafiltration process to ensure that water can pass through the ultrafiltration membrane. In home and small commercial ultrafiltration systems, low-pressure pumps are usually used, while in industrial applications, higher-pressure pumps may be required to meet large-scale processing needs.

The control system is used to monitor and adjust various parameters in the ultrafiltration process, such as water pressure, flow, membrane operation status, etc. Modern ultrafiltration systems are usually equipped with automated control systems that can monitor the system operation status in real time and automatically adjust parameters when necessary to ensure the stability and efficiency of the system.

How to maintain and service the ultrafiltration treatment system?

As the use time increases, a certain amount of pollutants may accumulate on the surface of the ultrafiltration membrane, resulting in a decrease in the flux of the membrane. Regularly cleaning the membrane surface can effectively remove the accumulated pollutants and restore the filtration capacity of the membrane. The cleaning process usually includes two methods: physical cleaning and chemical cleaning. Choose the appropriate cleaning method according to the type of pollutant.

Secondly, regularly check the various components in the system, such as pumps, valves, pipes, etc., to ensure that they are in good operating condition. For some wearing parts, such as sealing rings, filter elements, etc., they need to be replaced in time according to the use conditions to prevent affecting the normal operation of the system. And according to the use of the system, formulate a regular maintenance plan, including cleaning, inspection, and replacement of parts. Regular maintenance can effectively extend the service life of the system and ensure the long-term stability of water quality.