What type of control system is used in water treatment plants? What role does it play?

Water treatment plants play a key role in ensuring water supply safety and water quality compliance. In the water treatment process, the application of control systems is crucial.

This article will take a deep look at the various types of control systems used in water treatment plants and the role they play in the water treatment process.

How many types of water treatment plant control systems are there?

The control systems used in water treatment plants mainly include: programmable logic controller (PLC), distributed control system (DCS), supervisory control and data acquisition system (SCADA), human-machine interface (HMI) and these types.

1. Programmable Logic Controller (PLC)

PLC is a digital computer designed specifically for industrial environments and is widely used in automated control systems. Water treatment plants use PLCs to achieve automated control of equipment and processes. PLC systems have high reliability, stability, and programmability, and can flexibly respond to different process requirements.

2. Distributed Control System (DCS)

DCS is a computer system used for industrial process control that achieves coordinated control of the entire plant through distributed controllers. DCS is often used in water treatment plants to control complex process flows, and can achieve integrated management of various subsystems to improve the efficiency and reliability of the overall system.

3. Supervisory Control and Data Acquisition System (SCADA)

The SCADA system is used for real-time monitoring and data acquisition, and can monitor and record various parameters in the water treatment process. Through the SCADA system, operators can remotely monitor and control the operation of the water treatment plant, and promptly discover and solve problems.

4. Human-Machine Interface (HMI)

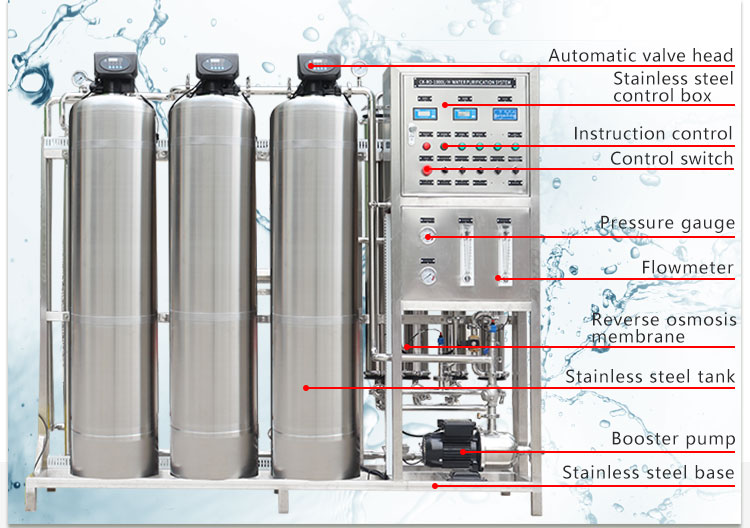

HMI is a user interface for human-computer interaction. The HMI system in the water treatment plant displays the process flow, equipment status and operating parameters through a graphical interface, and operators can operate and monitor through the HMI system.

What role does the control system play in a water treatment plant?

The control system plays a vital role in a water treatment plant, mainly in the following aspects: automated control and optimized operation, real-time monitoring and fault diagnosis, improving water quality and safety, energy saving and consumption reduction, and cost control.

1. Automated control and optimized operation

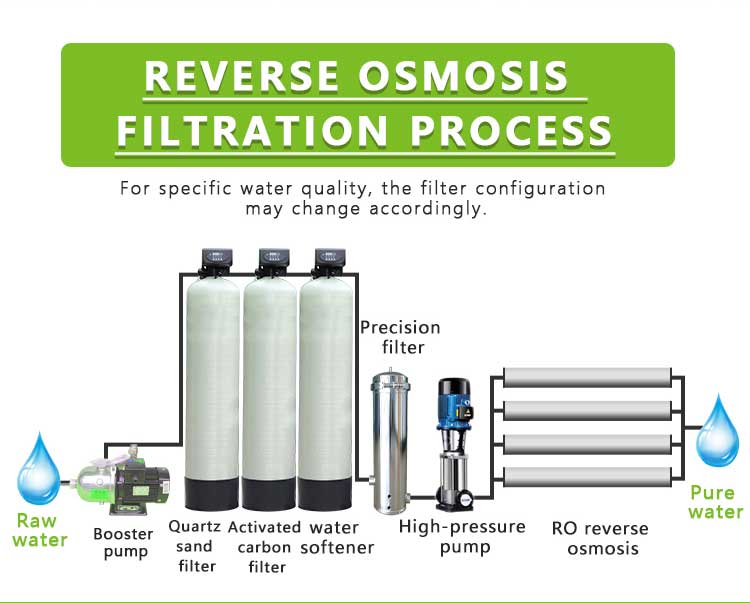

Modern water treatment plants use automated control systems to achieve automated control of each process link, including raw water pretreatment, coagulation, sedimentation, filtration, disinfection, etc. Through PLC and DCS systems, each link in the water treatment process can be automated, optimized operating parameters, and improved treatment efficiency and water quality.

For example, in the coagulation process control, the control system can automatically adjust the dosage and stirring speed according to the water quality parameters of the raw water to ensure that the coagulation effect reaches the best state. During the filtration process, the control system can automatically perform backwashing operations according to the operating status of the filter tank to ensure the cleanliness of the filter material and the filtration effect.

2. Real-time monitoring and fault diagnosis

The SCADA system can monitor various parameters in the water treatment process in real time, including water quality parameters (such as turbidity, pH value, dissolved oxygen, etc.) and equipment operating status (such as pump flow, pressure, current, etc.). Through the SCADA system, operators can monitor the operation of the water treatment plant in real time and discover and solve problems in a timely manner.

For example, if the flow rate of the pump suddenly drops, the SCADA system can issue an alarm in time to prompt the operator to check the operating status of the pump to avoid water treatment interruption caused by equipment failure. At the same time, the SCADA system can also record and store operating data to facilitate fault diagnosis and maintenance decisions.

3. Improve water quality and safety

The control system can accurately control various process parameters in the water treatment plant to ensure that the effluent water quality meets the standards. Through automated control and real-time monitoring, process parameters can be adjusted in time to avoid water quality fluctuations and pollution incidents.

For example, during the disinfection process, the control system can automatically adjust the dosage of disinfectant according to the water quality parameters of the effluent water to ensure that the residual chlorine concentration in the effluent water remains within a safe range to avoid secondary pollution. At the same time, through the remote monitoring function of the SCADA system, centralized management and control of the water treatment plant can be achieved, improving the safety and reliability of water treatment.

4. Energy saving and cost control

The application of the control system can optimize the energy and resource consumption in the water treatment process and reduce operating costs. Through automated control and optimized operation, the waste of energy and reagents can be reduced and the efficiency of resource utilization can be improved.

For example, by optimizing the operating parameters of the pump, the power consumption can be reduced; by accurately controlling the dosage, the waste of the agent can be reduced. In addition, through the monitoring and data analysis of the SCADA system, the problems of high energy consumption and high consumables can be discovered and solved, and energy saving and cost control can be achieved.

Actual case analysis

In order to better understand the application of control systems in water treatment plants, let's look at several actual cases.

Case 1: Application of PLC and DCS systems in a certain city's water plant

A certain city's water plant uses PLC and DCS systems to realize the automatic control and integrated management of the water treatment process. Through the PLC system, the automatic control and optimized operation of various links such as the raw water pump room, coagulation sedimentation, sand filter tank, and disinfection are realized. The DCS system integrates and coordinates the control of the entire water treatment plant, improving the stability and reliability of the system.

Through the application of PLC and DCS systems, the treatment capacity and water quality of the water plant have been significantly improved, and the effluent water quality has been stably up to standard. At the same time, through automatic control and optimized operation, energy and agent consumption have been significantly reduced, and operating costs have been greatly reduced.

Case 2: Application of SCADA system in an industrial wastewater treatment plant

An industrial wastewater treatment plant uses SCADA system to monitor and collect data of wastewater treatment process in real time. Through SCADA system, operators can monitor various parameters in wastewater treatment process in real time, including pH value, COD concentration, operation status of treatment equipment, etc.

The application of SCADA system improves the transparency and controllability of wastewater treatment process, and operators can find and solve problems in time to avoid environmental pollution accidents. At the same time, through data recording and analysis, wastewater treatment plant can optimize process parameters, reduce operating costs, and improve wastewater treatment efficiency and effect.

Conclusion

Water treatment plants use various types of control systems, including PLC, DCS, SCADA and HMI. Control system plays an important role in water treatment plants in automation control, real-time monitoring, improving water quality and safety, energy saving and consumption reduction, and cost control.

Through the application of control system, water treatment plants can improve treatment efficiency and water quality, reduce operating costs, and ensure water supply safety and environmental protection.