What water treatment equipment does the glass industry have?

In modern industry, water treatment technology plays a vital role in the sustainable development of various industries. As one of the industries with high water consumption and high wastewater discharge, the glass industry has an urgent need for water treatment equipment.

This article will discuss in detail the commonly used water treatment equipment in the glass industry, analyze its functions, advantages and disadvantages and application examples.

What is the importance of water and wastewater treatment in the glass industry?

In the glass production process, water is widely used in cooling, cleaning and chemical reactions. If the wastewater generated in the production process is directly discharged without treatment, it will not only pollute the environment, but also waste precious water resources. Therefore, the glass industry needs to be equipped with professional water treatment equipment to achieve the recycling of water resources and the standard discharge of wastewater.

What water treatment equipment does the glass industry have?

1. Filtration equipment:

1.1 Sand filter: The sand filter filters suspended matter and particulate matter in the water through a multi-layer quartz sand filter bed, which is suitable for the pretreatment stage of the glass industry. The main advantages of the sand filter are simple structure, stable operation and convenient maintenance, but the treatment effect on smaller particulate matter and soluble substances is limited.

1.2 Activated carbon filter: Activated carbon filter uses the adsorption characteristics of activated carbon to remove organic matter, odor and some heavy metals in water. It is used to remove impurities in water and improve water quality during glass production. The advantage of activated carbon filter is strong adsorption capacity, but the activated carbon needs to be replaced regularly to maintain the filtering effect.

2. Ion exchange equipment:

Ion exchange equipment removes dissolved salts such as calcium and magnesium ions in water through ion exchange resin, thereby reducing the hardness of water. In glass production, softened water is very important for the stability of cooling systems and chemical reactions. The advantages of ion exchange equipment are good treatment effect and low operating cost, but resin regeneration requires the use of chemical agents, which has a certain impact on the environment.

3. Ultrafiltration equipment:

Ultrafiltration equipment uses ultrafiltration membrane separation technology to remove suspended matter, bacteria and macromolecular organic matter in water, and is suitable for water reuse and wastewater treatment in glass production. The advantages of ultrafiltration equipment are high filtration accuracy and small footprint, but the membrane has a limited service life and needs to be cleaned and replaced regularly.

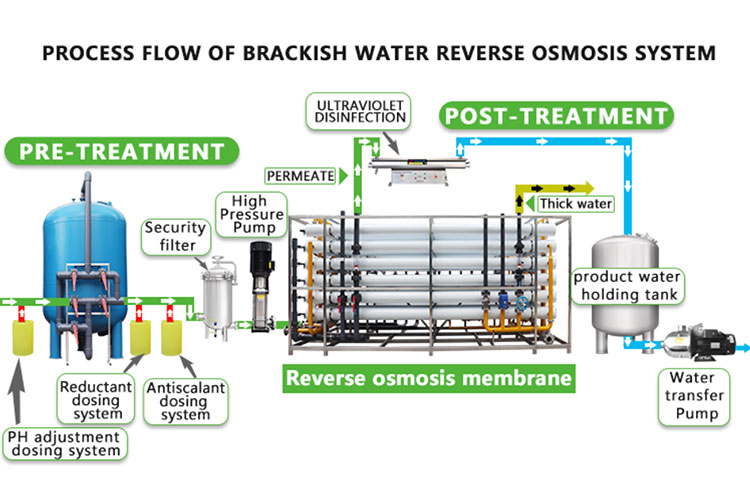

4. Reverse osmosis equipment:

Reverse osmosis equipment uses a semipermeable membrane to separate water under pressure to remove salts, heavy metals and organic matter in the water. It is widely used in the preparation of pure water in the glass industry. The main advantage of reverse osmosis equipment is that it has excellent treatment effect and can obtain high-purity water, but the initial investment is high and the energy consumption during operation is large.

5. Neutralization equipment:

Neutralization equipment adjusts the pH value of wastewater by adding acid or alkali to meet the discharge standard. In the process of glass production, acid and alkaline wastewater is more common and needs to be treated by neutralization equipment. Its advantages are rapid adjustment and simple operation, but the treatment process requires precise control of the dosage of the agent.

6. Biological treatment equipment:

Biological treatment equipment uses microorganisms to decompose organic pollutants in water and is suitable for wastewater treatment in the glass industry. It includes anaerobic reactors, aerobic biological treatment tanks, etc. The advantages of biological treatment equipment are low treatment cost and environmental protection, but the treatment time is long and the operating environment requirements are high.

Application examples of water treatment equipment in the glass industry

1. Case 1: A large glass manufacturing plant:

A large glass manufacturing plant uses a comprehensive water treatment system that combines sand filters, activated carbon filters, ion exchange equipment and reverse osmosis equipment. The production water is pretreated by sand filters and activated carbon filters to remove suspended matter and organic impurities; the ion exchange equipment softens the water quality and reduces the hardness of the water; the reverse osmosis equipment further purifies it to obtain high-quality production water. This system effectively guarantees the stability of the production process, improves product quality, and realizes the recycling of water resources.

2. Case 2: A glass factory wastewater treatment project:

Another glass factory used a combination of ultrafiltration equipment, neutralization equipment and biological treatment equipment in its wastewater treatment project. Ultrafiltration equipment removes suspended matter and macromolecular organic matter in wastewater; neutralization equipment adjusts the pH value of wastewater to meet emission standards; biological treatment equipment uses microorganisms to further decompose organic pollutants in wastewater. The implementation of this system enables wastewater treatment to meet environmental emission standards and effectively reduces environmental pollution.

What are the advantages and disadvantages of water treatment equipment in the glass industry?

Advantages of water treatment equipment in the glass industry:

1. Efficient filtration: Various filtration equipment can effectively remove impurities in water and ensure the quality of production water.

2. Environmental protection and energy saving: Through the use of water treatment equipment, water resources can be recycled, wastewater discharge can be reduced, and water resources can be saved.

3. Stable process: High-quality water treatment equipment can ensure the stability of the production process, improve product quality and production efficiency.

Disadvantages of water treatment equipment in the glass industry:

1. High initial investment: Some high-end water treatment equipment, such as reverse osmosis equipment, have a large initial investment, which increases the financial pressure of the enterprise.

2. High maintenance cost: Water treatment equipment requires regular maintenance and replacement of consumables, such as activated carbon, membrane components, etc., which increases operating costs.

3. Complex operation: Some equipment has high technical requirements for operators and requires professional training and technical support.

Summary

In the glass industry, the selection and application of water treatment equipment is of great significance to ensure production processes, improve product quality, and achieve environmental protection and energy saving. The problems of production water and wastewater treatment can be effectively solved by rationally configuring filtration equipment, ion exchange equipment, ultrafiltration equipment, reverse osmosis equipment, neutralization equipment and biological treatment equipment.