Which water treatments require deionized water systems?

Deionized water systems play an indispensable role in modern industry, laboratories, medical treatment, pharmaceuticals, electronic manufacturing and other fields. Deionized water (DI Water) is high-purity water obtained by removing ionized substances (such as salts and minerals) from raw water through a deionized water system. Because it contains almost no impurities and ions, deionized water is widely used in many occasions that require high-purity water.

So, which water treatment processes require the use of deionized water systems? This article will explore this issue in depth and analyze the specific applications of deionized water systems in various fields.

What are the basic principles of deionized water systems?

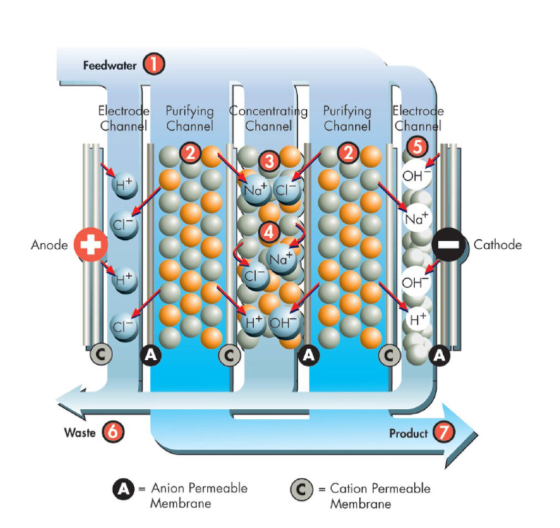

Before discussing specific applications, we first need to understand the basic principles of deionized water systems. Deionized water systems remove cations (such as calcium, magnesium, sodium) and anions (such as chlorides and sulfates) in water through ion exchange resins to generate pure water. This process usually includes the following steps:

1. Cation exchange: The raw water first passes through a column filled with cation exchange resins, which capture cations in the water and release hydrogen ions (H⁺).

2. Anion exchange: Next, the water passes through a column filled with anion exchange resins, which capture anions in the water and release hydroxide ions (OH⁻).

3. Neutralization reaction: The released hydrogen ions and hydroxide ions combine to form pure water (H₂O).

Through the above process, all ions in the water are removed, and the final deionized water contains almost no soluble salts or minerals, and has extremely low conductivity, close to the standard of pure water.

Which water treatments require a deionized water system?

Laboratory water treatment

The requirements for water quality in laboratories are extremely strict, especially in the fields of chemical analysis, biological experiments, cell culture, drug development, etc., where ions and impurities in water may directly affect the accuracy of experimental results. Therefore, laboratories often need to use deionized water systems to prepare ultrapure water.

1. Chemical analysis: In chemical analysis, especially when it comes to trace analysis (such as ICP-MS, HPLC, etc.), impurities in water may interfere with the test results. The high purity of deionized water can minimize this interference and ensure the accuracy of experimental data.

2. Biological experiments: Cell culture and molecular biology experiments also have very high requirements for water quality. Ions and organic impurities in water may have adverse effects on cell growth and even cause experimental failure. Deionized water can provide a pure environment, which helps the smooth progress of cell and molecular biology experiments.

3. Drug development: In the process of drug development, deionized water is widely used for reagent dissolution, sample preparation and cleaning equipment. The use of deionized water can prevent impurities in water from reacting with reagents, thereby improving the efficiency and accuracy of drug research and development.

Electronic manufacturing field

The requirements for water quality in the field of electronic manufacturing are also extremely high, especially in the production process of semiconductors and microelectronic components, impurities in water may cause circuit short circuits or damage tiny electronic components. Therefore, deionized water systems occupy an important position in electronic manufacturing.

1. Semiconductor manufacturing: Many steps in the semiconductor manufacturing process, such as wafer cleaning, etching and photolithography, require the use of high-purity deionized water. If impurities and ions in the water remain on the surface of the wafer, the produced chip may not work properly. Therefore, the deionized water system is one of the core equipment of the semiconductor factory.

2. Microelectronic component cleaning: Microelectronic components need to be cleaned many times during the manufacturing and assembly process to remove residual chemical reagents and tiny particles. The high purity of deionized water makes it an ideal cleaning solvent that can effectively remove tiny contaminants and ensure the quality and performance of components.

Medical and pharmaceutical industries

In the medical and pharmaceutical industries, water quality has a direct impact on the safety and effectiveness of products. Deionized water systems are widely used in these fields to prepare drugs, clean equipment, and produce water for injection.

1. Drug production: In the production process of drugs, deionized water is used to prepare drug solutions, dilute raw materials, and clean production equipment. High-purity deionized water can prevent ions and impurities in the water from chemically reacting with drug ingredients, thereby ensuring the quality and safety of drugs.

2. Medical equipment cleaning: Hospitals and medical equipment manufacturers need to use deionized water to clean surgical instruments and other medical equipment. If ions and impurities in the water remain on the surface of the equipment, it may cause infection or other medical accidents. The use of deionized water can provide a sterile, ion-free cleaning environment.

3. Production of water for injection: Deionized water is also one of the important raw materials for the production of water for injection. Water for injection requires extremely high purity. The deionized water system can remove all ions and organic impurities in the water to ensure the safety of water for injection.

Power and energy industry

In the power and energy industry, deionized water systems are mainly used for the treatment of boiler feed water and cooling water. If ions in water enter the boiler or cooling system, it may cause scaling, corrosion and equipment failure. The deionized water system can effectively remove ions in the water to prevent these problems from occurring.

1. Boiler feed water treatment: Boilers need to use a large amount of water to generate steam during operation. If the ion content in the boiler feed water is too high, scale may form in the boiler, resulting in reduced thermal efficiency or even equipment damage. The deionized water system can remove ions in the feed water and extend the service life of the boiler.

2. Cooling water treatment: Many equipment in the power and energy industries require cooling water to maintain normal operation. Deionized water can prevent corrosion and scaling problems in the cooling system and ensure long-term stable operation of the equipment.

Food and beverage industry

In the production process of food and beverages, the purity of water directly affects the taste, quality and safety of the product. Deionized water systems are widely used in food and beverage production water, equipment cleaning and product formulation.

1. Beverage production: Many beverage formulations require pure water. Deionized water can remove ions and impurities in water to ensure the taste and quality of the beverage. Especially in the production of high-end mineral water, purified water and other high-quality beverages, deionized water is an indispensable raw material.

2. Food processing: In the food processing process, deionized water is used for raw material cleaning, product dilution and equipment cleaning. The use of deionized water can prevent ions in water from reacting with food ingredients, affecting the taste and shelf life of food.

Optical and precision instrument manufacturing

The requirements for water quality in the optical and precision instrument manufacturing process are also extremely strict. Deionized water is used in the cleaning and assembly process to remove impurities in the water and ensure the high quality and high precision of optical components and precision instruments.

1. Optical component cleaning: In the manufacturing process of optical lenses, optical lenses and other components, the cleaning step is very critical. Ions and tiny particles in the water may leave marks or cause scratches on the surface of the lens. These tiny flaws can seriously affect the optical performance of the lens. The use of deionized water can completely remove these tiny contaminants and ensure the purity and transparency of optical components.

2. Precision instrument manufacturing: In the process of manufacturing and assembling precision instruments, any tiny contamination may cause measurement errors or functional failure of the instrument. Deionized water systems play an important role in these processes. It provides a pure water source for the cleaning and assembly process, ensuring that the cleanliness of all components meets the highest standards, thereby ensuring the accuracy and reliability of the final product.

Automotive and aviation industries

The automotive and aviation industries also rely on high-purity deionized water in the manufacturing process, especially in the production of engines and other key components.

1. Engine coolant production: The coolant of automotive and aircraft engines requires extremely high purity to prevent corrosion and scaling in the cooling system. Deionized water is widely used in the preparation of coolants to ensure that the coolant does not cause any damage to the engine and increase its service life.

2. Surface treatment and painting: In the surface treatment and painting process of automobiles and aircraft, deionized water is used to clean the surface to ensure that the coating is uniform and firmly attached. Impurities in the water may cause the coating to bubble, fall off or have defects, affecting the appearance and durability of the vehicle or aircraft.

Chemical production

Many production processes in the chemical industry require high-purity water to avoid interference from impurities in the reaction. Deionized water systems also play an important role in these processes.

1. Chemical reaction solvent: In some fine chemical production, deionized water is widely used as a reaction solvent. If the ions and impurities in the water are not effectively removed, they may react with the chemical raw materials, affecting the purity of the product and the reaction efficiency.

2. Reagent dilution: Deionized water is often used to dilute chemical reagents to ensure the purity of the reagents and the consistency of the reaction. Especially when producing high-precision chemicals, the purity of water quality is crucial.

In summary, deionized water systems are considered the standard for high-purity water sources in laboratories, electronic manufacturing, medical treatment, pharmaceuticals, electricity, food, optical manufacturing, automotive aviation, chemical production, etc. This pure water system can effectively remove ions and impurities in water, providing a reliable solution for various occasions that require high-purity water.