How much does it cost to maintain a 2-ton RO water treatment system?

Reverse osmosis (RO) water treatment systems are becoming more and more popular in industrial, commercial and domestic applications, especially those that require high-quality water sources. For users who own or plan to install a 2-ton reverse osmosis water treatment system, it is necessary to understand its maintenance costs.

This article will explore in detail the cost components of maintaining a 2-ton reverse osmosis water treatment system, including equipment maintenance, chemical use, electricity consumption and labor costs, to help users make budgets and cost control.

What is the importance of maintaining a reverse osmosis water treatment system?

Reverse osmosis water treatment systems use membrane technology to remove dissolved salts, organic matter, bacteria and other impurities in water to provide high-purity water sources. However, during long-term operation, the various components of the system will be affected by water quality and operating conditions, and problems such as wear, blockage and contamination will occur. If regular maintenance is not performed, the system's filtration efficiency and water quality will decrease, and may even cause equipment failure and downtime. Therefore, regular maintenance can not only ensure the normal operation of the system, but also extend the service life of the equipment and reduce long-term operating costs.

What are the main maintenance items of a 2-ton reverse osmosis water treatment system?

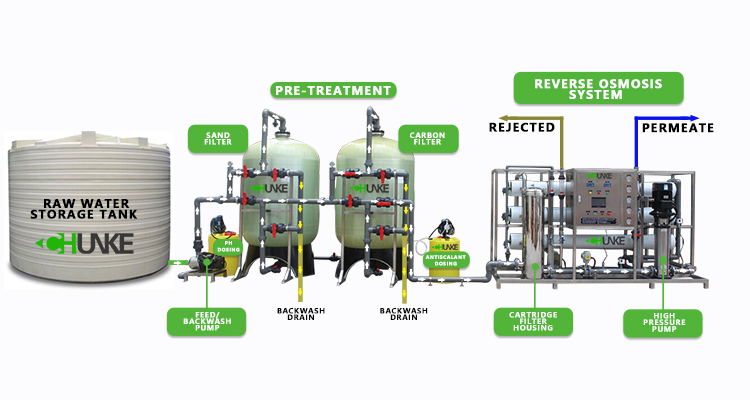

The main maintenance items of the 2-ton reverse osmosis water treatment system are: pretreatment equipment maintenance, reverse osmosis membrane cleaning, high-pressure pump maintenance, pipeline and accessories inspection, and control system maintenance.

1. Pretreatment equipment maintenance:

● Pretreatment equipment such as mechanical filters, activated carbon filters and softeners need to regularly replace filter materials and resins to ensure that they effectively remove suspended matter, residual chlorine and hardness ions in the influent water to prevent damage and scaling of the reverse osmosis membrane.

2. Reverse osmosis membrane cleaning:

● The reverse osmosis membrane is the core component of the system. During long-term operation, it will be contaminated by organic matter, inorganic matter and microorganisms in the water, resulting in decreased membrane flux and deterioration of produced water quality. Regular chemical cleaning can remove pollutants on the membrane surface and restore the filtration performance of the membrane.

3. High-pressure pump maintenance:

● The high-pressure pump provides the necessary pressure for the reverse osmosis process and is an important equipment to ensure the normal operation of the system. Regularly check and maintain the high-pressure pump to ensure that its lubrication, cooling and sealing systems work properly to prevent wear and damage to the pump.

4. Inspection of pipes and accessories:

● Pipes and accessories connect various system components and need to be regularly checked for leaks, blockages, corrosion, etc., and damaged parts should be replaced in time to ensure stable operation of the system.

5. Control system maintenance:

● The control system monitors and adjusts system operating parameters in real time through sensors and controllers, regularly calibrates sensors and checks controllers to ensure their accuracy and reliability and prevent system abnormalities.

How much does it cost to maintain a 2-ton reverse osmosis water treatment system?

1. Equipment maintenance cost:

● Equipment maintenance costs mainly include replacement of filter materials, resins, reverse osmosis membranes and high-pressure pump parts. Depending on the frequency of use and water quality, pretreatment filter materials and resins are usually replaced every 6 months to 1 year, reverse osmosis membranes are replaced every 2 to 5 years, and high-pressure pump parts are replaced regularly according to usage.

● Pretreatment filter material and resin replacement cost: about $300-500 per year

● Reverse osmosis membrane replacement cost: about $1000-2000 every 2-5 years

● High-pressure pump parts replacement cost: about $200-400 per year

2. Chemical use cost:

● Chemical cleaning agents and disinfectants are important substances to ensure the cleanliness of reverse osmosis membranes and other system components, and need to be used regularly according to water quality and usage. Common cleaning agents include acidic cleaning agents, alkaline cleaning agents and bactericides.

● Chemical cleaning agent cost: about $500-800 per year

● Disinfectant cost: about $200-400 per year

3. Power consumption cost:

● The power consumption of the reverse osmosis water treatment system mainly comes from the high-pressure pump and control system. The power consumption cost is calculated based on the system's operating time and electricity price.

● High-pressure pump power consumption: about $1,000-1,500 per year

● Control system power consumption: about $200-300 per year

4. Labor costs:

● Maintenance of the reverse osmosis water treatment system requires professional technicians to inspect, clean and replace parts. Labor costs are calculated based on the maintenance frequency and the technician's salary standard.

● Labor costs: about $1,000-1,500 per year

5. Miscellaneous expenses:

● Miscellaneous expenses include maintenance tools, instrument calibration, maintenance materials and emergency repair costs, etc.

● Miscellaneous expenses: about $300-500 per year

Total annual maintenance cost of a 2-ton reverse osmosis water treatment system

Combining the above costs, the total annual cost of maintaining a 2-ton reverse osmosis water treatment system is roughly as follows:

1. Equipment maintenance cost: $300-500 (filter material and resin) + $1000-2000 (reverse osmosis membrane, average every 2-5 years) + $200-400 (high-pressure pump parts)

● Average annual total cost: $1500-2900

2. Chemical use cost: $500-800 (cleaning agent) + $200-400 (disinfectant)

● Average annual total cost: $700-1200

3. Power consumption cost: $1000-1500 (high-pressure pump) + $200-300 (control system)

● Average annual total cost: $1200-1800

4. Labor cost:

● Average annual total cost: $1,000-1,500

5. Miscellaneous expenses:

● Average annual total cost: $300-500

How to reduce the maintenance cost of the reverse osmosis water treatment system?

1. Optimize pretreatment equipment: Select efficient and durable pretreatment equipment, extend the replacement cycle of filter materials and resins, and reduce maintenance frequency and costs.

2. Regular monitoring and adjustment: Regularly monitor the inlet water quality and system operating parameters, adjust the operating conditions in time, avoid equipment overload and membrane pollution, and extend the service life of the reverse osmosis membrane and high-pressure pump.

3. Use high-quality chemicals: Select high-quality chemical cleaning agents and disinfectants to ensure cleaning effects and equipment safety, reduce cleaning frequency and chemical usage.

4. Train technicians: Improve the professional skills of maintenance technicians, reduce human operating errors and equipment damage, and improve maintenance efficiency and effectiveness.

5. Regular maintenance and care: Develop a detailed maintenance and care plan, conduct equipment inspection and maintenance on time, prevent equipment failures and downtime, and reduce long-term maintenance costs.

Summary of the cost of maintaining a 2-ton reverse osmosis water treatment system

The annual cost of maintaining a 2-ton reverse osmosis water treatment system is approximately between $3,700 and $6,900, depending on the quality of the equipment, water quality conditions, frequency of use, and maintenance management level. By optimizing pretreatment equipment, regularly monitoring and adjusting operating conditions, using high-quality chemicals, training technicians, and developing detailed maintenance plans, users can effectively reduce maintenance costs, ensure long-term and efficient operation of the system, and provide high-quality water for production and life.