How to treat poultry drinking water?

Poultry farming is an important part of agriculture, providing a large amount of meat and egg products. In order to ensure the healthy growth of poultry, the quality of drinking water is crucial. Bacteria, viruses, parasites, heavy metals and other pollutants in water sources may pose a threat to poultry. Therefore, how to effectively treat poultry drinking water has become a key issue of concern to farmers.

So, what kind of equipment is both convenient to use and cost-effective? This article will explore this issue in detail.

What is the importance of poultry drinking water treatment?

The quality of poultry drinking water directly affects their health and production performance. Contaminated water sources may cause poultry to suffer from a variety of diseases, such as intestinal infections, respiratory diseases, and may even spread serious infectious diseases. In addition, poor water quality may also affect the appetite of poultry, thereby reducing production efficiency. Therefore, treating poultry drinking water is an important measure to ensure the health of poultry.

What are the common sources of poultry drinking water pollution?

Microorganisms such as bacteria, viruses, molds and parasites in water sources are the main sources of pollution in poultry drinking water. These microorganisms may cause poultry infections, especially in hot seasons and environments with high humidity. Water may also contain chemical pollutants such as pesticides, heavy metals (such as lead and mercury), and ammonia nitrogen. These substances are not only harmful to poultry, but may also enter the human body through the food chain and endanger human health.

In addition, organic substances such as humus and animal excrement can pollute water sources, causing water quality deterioration and may cause gastrointestinal problems in poultry. There is also the problem of hard water. The high content of minerals (such as calcium and magnesium) in the water increases the hardness of the water, which not only affects the quality of poultry drinking water, but may also cause scaling and damage to drinking water equipment.

How to treat poultry drinking water?

In order to ensure the safety and quality of poultry drinking water, the following are several common water treatment methods:

Sedimentation method:

Sedimentation is the simplest water treatment method and is suitable for treating suspended matter and larger particles in water. Some organic matter and inorganic particles can be removed by natural sedimentation or by adding flocculants (such as alum) to accelerate the sedimentation process.

Advantages of sedimentation method:

● Low cost and simple operation. ● It has a certain effect on farms that do not require high water quality.

Disadvantages of sedimentation method:

● It is only suitable for the removal of coarse particles, and cannot remove microorganisms and soluble pollutants.

● The sedimentation time is long and the efficiency is low.

Filtration method:

The filtration method removes particulate matter and suspended matter in the water through physical barriers (such as sand filters, fiber filters, etc.). Sand filters are the most common filtration equipment, suitable for removing larger particles and some organic matter.

Advantages of filtration method:

● It can effectively remove suspended particles and silt.

● Simple operation and maintenance, and a wide range of applications.

Disadvantages of filtration method:

● It cannot remove soluble pollutants and microorganisms.

● The filter material needs to be replaced regularly, which increases the maintenance cost.

Ultraviolet disinfection:

Ultraviolet disinfection is an efficient physical disinfection method. Through ultraviolet irradiation, the DNA of microorganisms in the water is destroyed, making them lose their reproductive ability, thereby achieving the purpose of disinfection.

Advantages of ultraviolet disinfection:

● Highly efficient sterilization, no chemical residue.

● The equipment is easy to operate and does not change the physical and chemical properties of water.

Disadvantages of UV disinfection:

● There are certain requirements for water quality. When there are too many suspended solids in the water, the disinfection effect will decrease.

● The initial investment of the equipment is high, and the lamp needs to be replaced regularly.

Chlorine disinfection:

Chlorine disinfection is the most common chemical disinfection method. It kills bacteria, viruses and algae in the water by adding chlorine or sodium hypochlorite to the water. This method is widely used in large-scale farms and municipal water supply systems.

Advantages of chlorine disinfection:

● Good bactericidal effect, suitable for various water qualities.

● Low cost, suitable for large-scale use.

Disadvantages of chlorine disinfection:

● Byproducts (such as chloroform) may be produced, which are potentially harmful to poultry and humans.

● Special equipment and technicians are required to operate.

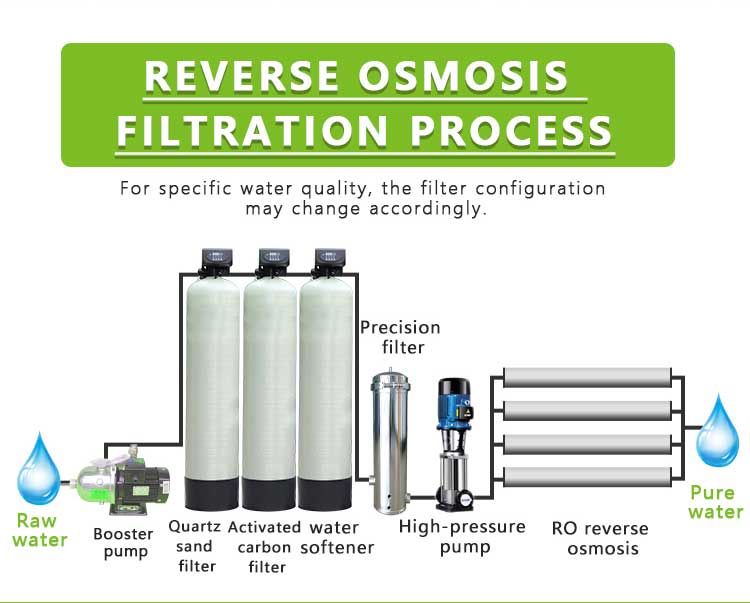

Reverse osmosis (RO) system:

The reverse osmosis system removes dissolved salts, heavy metals, organic matter, etc. in the water through a semi-permeable membrane to provide high-purity drinking water. This system is widely used in household drinking water and some high-demand farms.

Advantages of reverse osmosis system:

● It can remove almost all soluble pollutants and the water quality is very pure.

● Suitable for high-demand breeding environments.

Disadvantages of reverse osmosis system:

● High cost and complex equipment maintenance.

● Low water production rate and large wastewater discharge.

What equipment is suitable for poultry drinking water treatment?

After understanding various water treatment methods, farmers need to choose the most suitable equipment according to their actual situation. The following are several equipment recommendations for poultry drinking water treatment:

Ultraviolet disinfection:

For farms of a certain scale, ultraviolet disinfection is an ideal choice. It can effectively kill pathogenic microorganisms in water and ensure the hygiene and safety of poultry drinking water. At the same time, ultraviolet disinfection will not change the taste and properties of water, which is very suitable for breeding environments with high water quality requirements.

Recommendations:

● Check the working status of the lamp regularly and replace the lamp according to the use.

● Ensure that the suspended matter content in the water is not high to avoid affecting the disinfection effect.

Sand filter combined with chlorine disinfection system:

If there are more suspended matter in the water source, you can use a sand filter for preliminary filtration first, and then use a chlorine disinfection system for sterilization. This combination can effectively remove most pollutants and the cost is relatively low.

Recommendations:

● Clean the filter material in the sand filter regularly to ensure the filtering effect.

● Control the amount of chlorine to avoid adverse effects on poultry.

Simple sedimentation tank combined with manual filtration equipment:

For small farms or farmers with limited funds, you can choose a simple sedimentation tank combined with manual filtration equipment. Although the treatment effect of this method is not as good as the previous two methods, it has obvious advantages in economy.

Recommendations:

● Clean the sedimentation tank regularly to prevent sludge accumulation.

● Manual filtration equipment should be easy to operate and maintain.

What equipment is the most convenient and cost-effective?

When choosing poultry drinking water treatment equipment, farmers should choose appropriate treatment methods and equipment according to the type and content of pollutants in the water source. If there are many pollutants in the water and the types are complex, it is recommended to choose a multi-stage treatment system. Large-scale farms require efficient and highly automated equipment, while small farms can choose lower-cost manual or semi-automatic equipment.

Although high-end equipment can provide better treatment results, its initial investment and maintenance costs are also higher. Farmers need to find a balance between equipment performance and cost and choose the most cost-effective solution. In addition, some equipment requires professional operators and maintenance personnel, while others are relatively simple and easy to use. Choose the right type of equipment according to the actual operation capacity of the farm.

Conclusion

The treatment of poultry drinking water directly affects the health and production efficiency of poultry. Choosing the right water treatment equipment is crucial for farmers. Ultraviolet disinfection, sand filter combined with chlorine disinfection system, and simple sedimentation tank combined with manual filtration equipment are all common and effective choices.

Farmers should choose the most suitable treatment equipment according to the actual situation, comprehensively consider factors such as the degree of water source pollution, breeding scale, cost-effectiveness, and operation and maintenance, so as to ensure the safety of poultry drinking water and improve breeding efficiency.