What are the components of a standard water treatment system?

Water treatment systems are important equipment for ensuring drinking water safety, industrial water cleanliness and environmental protection. Whether it is domestic water, industrial water, or sewage treatment, water treatment systems play a vital role in purifying water quality and removing pollutants. However, a water treatment system is not a single device, but a complex system consisting of multiple parts and stages.

So, what are the components of a standard water treatment system? What functions do these parts each undertake? This article will explore this in detail.

Basic components of a standard water treatment system

A standard water treatment system usually consists of a pretreatment unit, a core treatment unit, a post-treatment unit, and auxiliary equipment. These parts work together to ensure that the water quality meets the expected standards. The following is a detailed description of each part:

1. Pretreatment unit:

Pretreatment is the first checkpoint of the water treatment system, which aims to remove large particle impurities, suspended matter, silt, and some organic matter in the water to prevent them from causing damage to subsequent treatment units. The pretreatment unit usually includes the following equipment:

● Screens and grilles: used to intercept larger solid impurities in the water, such as leaves, stones, plastic bags, etc.

● Grit chamber: The sediment in the water is settled by gravity, thereby reducing the burden on subsequent treatment units.

● Coagulant dosing device: By adding coagulants, the fine particles in the water are aggregated into larger particles, which is convenient for subsequent sedimentation or filtration treatment.

● Flocculation tank: In the flocculation tank, the added coagulant makes the particles further flocculate, thereby forming larger flocs, which is conducive to sedimentation and filtration.

2. Core treatment unit:

The core treatment unit is the "heart" of the entire water treatment system, which is mainly responsible for removing soluble pollutants, organic matter, bacteria, viruses, etc. in the water. This part usually includes the following treatment technologies:

● Sand filter: Filter using sand layers to remove suspended matter and flocculants in the water.

● Activated carbon filter: Activated carbon has a very strong adsorption capacity and can remove organic matter, residual chlorine, odor and some heavy metals in the water.

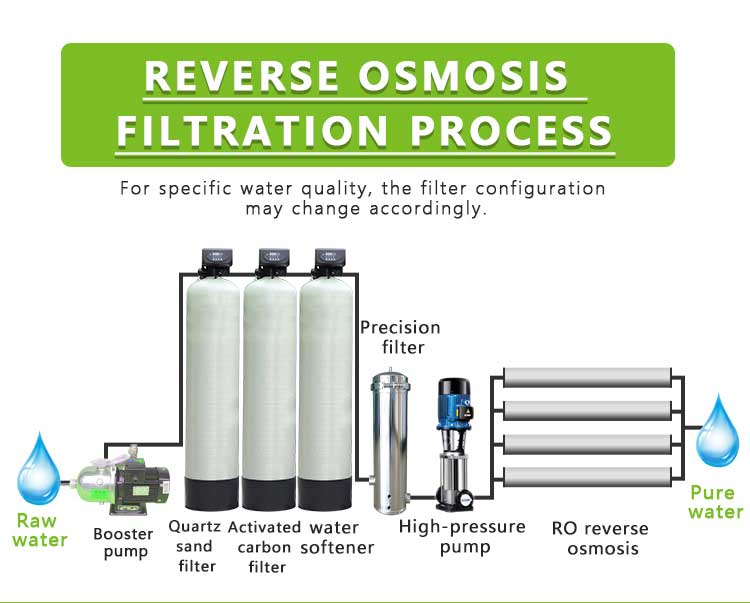

● Reverse osmosis device: It removes soluble salts, heavy metals, bacteria and viruses in the water through reverse osmosis membranes, and is widely used in deep purification of drinking water.

● Ion exchanger: used to remove hardness ions (calcium and magnesium ions) in water, reduce water hardness and prevent scaling.

● Ultrafiltration device: used to remove tiny particles, colloids, bacteria and some viruses in water.

3. Post-treatment unit:

After purification by the core treatment unit, the water quality has reached a certain standard, but in order to further ensure the safety and quality of the water, the post-treatment unit still needs to perform final treatment on the water. The post-treatment unit includes:

● Ultraviolet disinfector: Use the high energy of ultraviolet rays to destroy the DNA structure of bacteria and viruses in the water to achieve the purpose of disinfection.

● Ozone generator: By injecting ozone into the water, organic matter is further oxidized and pathogenic microorganisms are killed.

● Chlorine dioxide generator: used as a chemical disinfectant, it has a strong bactericidal effect and is not easy to form harmful disinfection by-products.

● Mineralization device: Add an appropriate amount of minerals to the treated pure water to improve the taste and provide trace elements required by the human body.

4. Auxiliary equipment:

Although auxiliary equipment does not directly participate in the water treatment process, it plays a key role in maintaining the stable operation of the system and monitoring water quality. Auxiliary equipment includes:

● Water quality monitoring instrument: real-time monitoring of pH value, turbidity, residual chlorine content, conductivity and other indicators in water to ensure the treatment effect.

● Flow meter: monitor the inlet and outlet flow of the water treatment system to ensure that the system operates under the designed load.

● Pressure gauge: monitor the pressure of each treatment unit to prevent equipment damage due to abnormal pressure.

● Pumps and valves: ensure the normal flow of water in the treatment system, and adjust the flow and direction as needed.

What is the workflow of a standard water treatment system?

The various parts of the water treatment system are closely connected in sequence to complete the water purification process together. The following is a typical workflow of a water treatment system:

1. Water inlet:

The water source (which may be river water, lake water, groundwater, seawater, etc.) first enters the pretreatment unit. After preliminary filtration by screens, grilles, etc., large particle impurities are removed and the water quality is initially purified.

2. Coagulation and sedimentation:

Water enters the coagulation tank, and after the coagulant is added, it forms larger particles through flocculation. Then, the water enters the sedimentation tank, where the floccules are settled by gravity, and the clean water flows to the next treatment unit.

3. Filtration and adsorption:

The water after sedimentation enters the sand filter and activated carbon filter to further remove the remaining suspended matter, organic matter and odor. At this point, most of the pollutants in the water have been removed.

4. Deep treatment:

The water that has passed through the core treatment unit will be treated by reverse osmosis or ultrafiltration. The reverse osmosis device removes salts and microorganisms in the water, and the ultrafiltration device removes the remaining tiny particles and pathogens. This process can ensure that the water quality meets high standards.

5. Disinfection and post-treatment:

The water is treated by ultraviolet disinfection or ozone generator to ensure that all microorganisms and bacteria are completely killed. If necessary, the water can also be supplemented with minerals through the mineralization device.

6. Water output and monitoring:

The treated water is tested by water quality monitoring instruments to ensure that the water quality meets the standards. Finally, after being controlled by pumps and valves, the purified water flows to the water storage tank or is directly supplied to users.

Differences in the configuration of water treatment systems in different application scenarios

Although standard water treatment systems have basic components and treatment processes, the system configuration and process selection will vary in different application scenarios.

The focus of drinking water treatment systems is to remove microorganisms, organic matter, heavy metals and other harmful substances to ensure that the water quality is safe, odorless and rich in appropriate minerals. Therefore, drinking water treatment systems usually use high-efficiency reverse osmosis devices, activated carbon filters, and ultraviolet disinfection equipment.

Industrial water treatment systems need to be adjusted according to different industrial needs. For example, boiler water requires low hardness and few impurities, so the system will focus on softeners and reverse osmosis devices. For cooling water treatment, the system needs to focus on corrosion and anti-scaling, and may use specific chemical treatment and circulation systems.

The configuration of sewage treatment systems mainly depends on water quality characteristics and discharge standards. Generally speaking, sewage treatment systems need to have functions such as deodorization, denitrification, and phosphorus removal, and meet discharge requirements through a combination of biological treatment, chemical treatment and physical treatment.