What happens if the reverse osmosis membrane does not work?

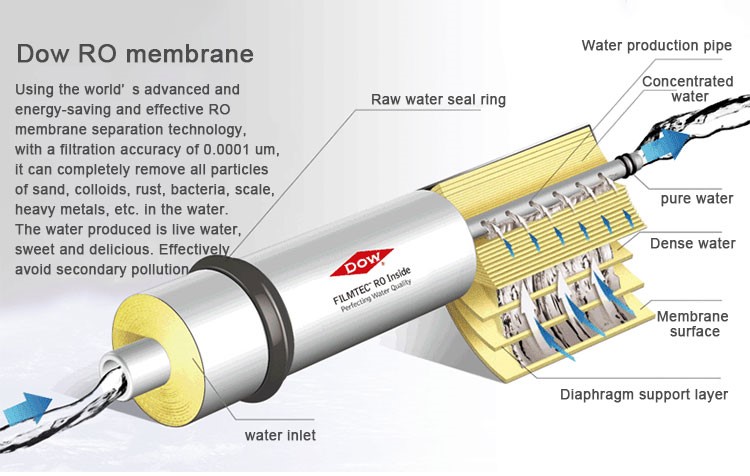

Reverse osmosis membrane (RO membrane) is a core component in water treatment systems and is widely used in drinking water purification, industrial water treatment, seawater desalination and other fields. However, due to its sophisticated structure and specific working conditions, the reverse osmosis membrane is easily affected by a variety of factors during use. Once there is a problem with the reverse osmosis membrane, its working efficiency and effect will be seriously affected, which may lead to a decline in water quality or even a complete loss of filtering function.

This article will delve into the consequences of reverse osmosis membrane failure and the main reasons for its damage, to help users better understand and maintain this key water treatment equipment.

What happens if the reverse osmosis membrane does not work?

The main function of the reverse osmosis membrane is to separate water molecules from the solution through high pressure, thereby removing impurities, salts and harmful substances from the water. If the reverse osmosis membrane does not work, the system will not be able to purify the water normally, which will directly affect the quality of the final water production.

The following situations may occur when the reverse osmosis membrane does not work:

1. The water output decreases sharply

2. The water quality deteriorates

3. The system pressure increases

4. The energy consumption of the equipment increases

5. The water treatment process is unstable

The water output decreases sharply

When the reverse osmosis membrane does not work properly, one of the most intuitive manifestations is a significant decrease in water output. This is because the membrane surface may be blocked or damaged, resulting in water being unable to pass through the membrane pores to the purified water output end. The reduction in water output not only affects the overall efficiency of the water treatment system, but may also cause users to be unable to obtain enough clean water, especially in applications with high water output requirements, such as industrial production or medical fields.

Deterioration of water quality

Another direct consequence of the reverse osmosis membrane not working is the deterioration of water quality. The reverse osmosis membrane is designed to filter out pollutants such as dissolved solids (TDS), microorganisms, organic matter and heavy metals in water. However, when the membrane fails, these pollutants may not be effectively removed, resulting in an increase in the TDS value of the water output, or even odor or color. Substandard drinking water quality may pose a potential threat to human health, while a decline in industrial water quality may affect product quality or the normal operation of production equipment.

Increased system pressure

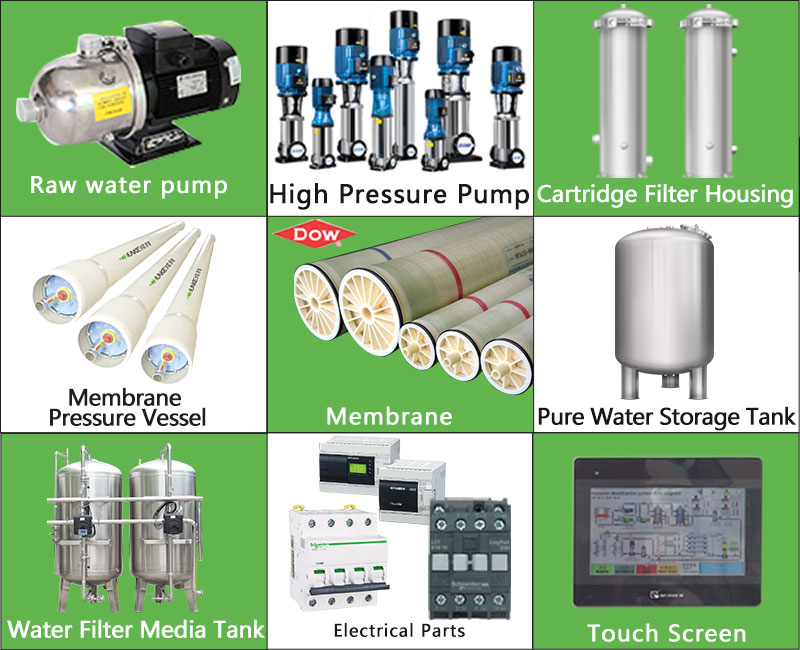

When the reverse osmosis system is working, it relies on a high-pressure pump to pressurize water into the membrane assembly, thereby pushing water molecules through the membrane. If the membrane is blocked or damaged, the resistance to water passage will increase significantly, resulting in increased pressure inside the system. This will not only accelerate the wear of the equipment, but may also cause safety issues, such as overload of the high-pressure pump or rupture of the pipeline. In addition, abnormally high system pressure is usually an early warning sign of membrane failure, and users should check and deal with it in time to avoid more serious consequences.

Increased equipment energy consumption

Improper operation of the reverse osmosis membrane will also lead to increased energy consumption in the water treatment system. When the membrane is blocked, the system requires higher energy to maintain normal water flow and pressure, which means that power consumption will increase significantly. In the long run, this not only increases operating costs, but may also impose additional burdens on the equipment, accelerating its aging and damage.

Unstable water treatment process

Under normal circumstances, the reverse osmosis membrane can stably remove most of the pollutants in the water and ensure the quality of the produced water. However, when membrane performance deteriorates or fails completely, the water treatment process will become unstable and the quality and quantity of produced water will fluctuate. This instability is particularly detrimental in situations where continuous and high-quality water production is required, such as food processing or pharmaceutical production, and may lead to downtime or product failures in the production process.

What can damage reverse osmosis membranes?

Reverse osmosis membrane damage can be caused by a variety of factors, including physical damage, chemical attack, biological contamination, and improper operation. Understanding these potential threats can help users take effective preventive measures to extend the life of the membrane.

Physical damage

Physical damage is one of the common causes of reverse osmosis membrane failure. The membrane may be subjected to external impact or compression during manufacturing and transportation, resulting in microcracks or breakage. In addition, during installation and use, improper operation, such as excessive pressure or forced compression of the membrane assembly, may also cause the membrane to rupture or the membrane shell to deform. Physical damage is usually irreversible, and once it occurs, the membrane assembly must be replaced.

Chemical attack

Reverse osmosis membranes have limited tolerance to chemicals, and certain chemicals will corrode the membrane material, resulting in damage to the membrane pore structure. For example, chloride is a common oxidant that can quickly oxidize and destroy polyamide membrane materials, resulting in a significant decrease in membrane performance. In order to avoid chemical erosion, a dechlorination device is usually installed at the front end during system design, or a chemically resistant membrane material is used. However, chemical erosion may still occur if the pretreatment is improper or the membrane material is not selected properly.

Biological fouling

Biological fouling refers to the growth and reproduction of microorganisms on the surface or inside the reverse osmosis membrane to form a biofilm, thereby blocking the membrane pores and affecting the flow of water. Biological fouling not only reduces the filtration effect of the membrane, but may also cause secondary microbial contamination and affect the quality of the produced water. The prevention of biological fouling mainly relies on the cleaning and disinfection procedures of the system and the effective control of microorganisms in the raw water during the pretreatment stage.

Improper operation

The operation of the reverse osmosis system needs to strictly follow the design specifications, and any improper operation may cause membrane damage. For example, if the system is not properly flushed when it is started, residual impurities may block the membrane pores. In addition, operational errors such as too high or too low operating pressure, frequent start and stop, and untreated influent water entering the membrane assembly will also cause irreversible damage to the membrane.

Poor water quality

The quality of influent water is an important factor affecting the life of the reverse osmosis membrane. High hardness water, excessive suspended solids concentration, excessive organic matter content, excessive microorganisms, etc. will increase the pollution burden of the membrane and accelerate the failure of the membrane. If the content of suspended solids and colloids in the influent water is high, it is easy to form a fouling layer on the membrane surface, increase the water resistance of the membrane, and reduce the water output and quality. Therefore, when using the reverse osmosis system, pre-treatment such as softening, filtration and sterilization is usually required to ensure that the influent water quality meets the requirements of the membrane.

Aging caused by long-term use

The materials of reverse osmosis membranes are mainly polymer materials such as polyamide and polypropylene. These materials will gradually age during long-term use, resulting in a decrease in the filtration performance of the membrane. The aging process may include weakening of the mechanical properties of the material, expansion of the membrane pores, and structural deformation. Although modern reverse osmosis membranes are usually designed to have a long life, the aging rate may accelerate under high-load and high-intensity use conditions, and the membrane components need to be regularly inspected and replaced.

How to prevent and deal with damage to reverse osmosis membranes?

In order to extend the service life of the reverse osmosis membrane and avoid unnecessary damage, users should pay attention to regular testing of the inlet water quality during use to ensure that it meets the requirements of the membrane. If necessary, add pretreatment steps such as softening, sedimentation and filtration. Start, operate and shut down the system in strict accordance with the operating manual to avoid sudden pressure changes or untreated inlet water directly entering the membrane assembly.

According to the frequency of use and water quality, the reverse osmosis membrane should be chemically cleaned and disinfected regularly to remove pollutants on the membrane surface and prevent biological contamination and chemical accumulation. When adding agents to the system, choose agents that are harmless to the membrane material and avoid using chemicals that may cause membrane damage, such as strong oxidants.

Through the above measures, the risk of damage to the reverse osmosis membrane can be effectively reduced to ensure the long-term stable operation of the water treatment system. As a key component in water treatment technology, the maintenance and care of the reverse osmosis membrane not only affects the service life of the equipment, but is also directly related to the quality and safety of the produced water.