What is 2000L/H EDI water treatment system? How does it work?

In today's era of high industrialization and technological development, the advancement of water treatment technology plays a vital role in many fields. The purity of water is directly related to product quality, process efficiency and environmental protection. Among many water treatment systems, EDI (Electrodeionization) technology has become an important choice in modern water treatment systems with its high efficiency, continuity and low cost.

This article will analyze in detail the working principle, components and practical application of 2000L/H EDI water treatment system in the field of water treatment.

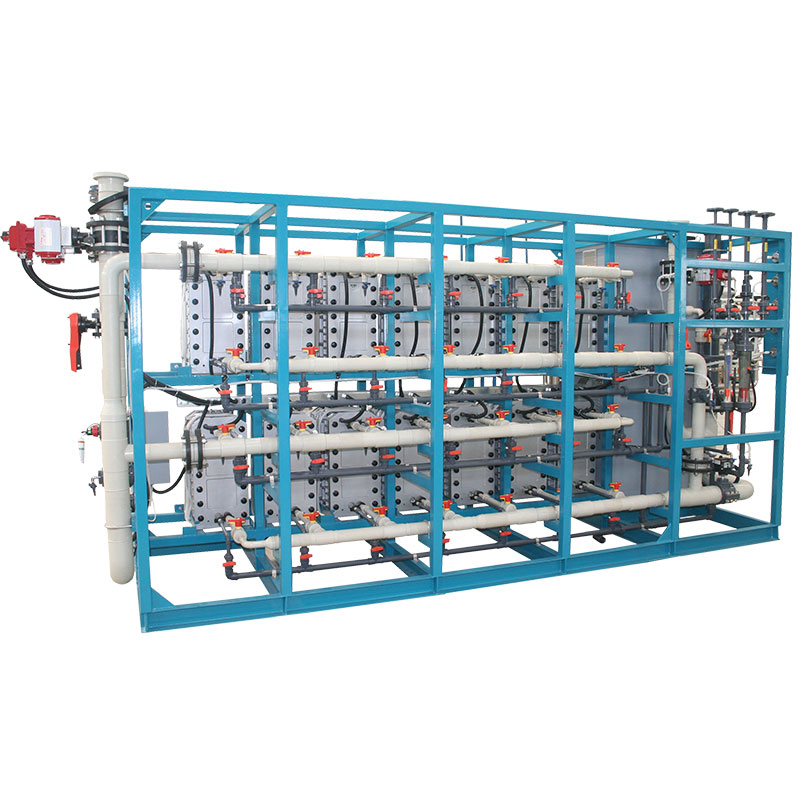

What is 2000L/H EDI water treatment system?

The EDI water treatment system is a new water treatment process that combines electrodialysis (ED) and ion exchange technology, mainly used to produce high-purity deionized water. Unlike traditional ion exchange equipment, the EDI system continuously removes ions from water through the action of an electric field to achieve the effect of deionization.

"2000L/H" means that the water output of the EDI system is 2000 liters per hour. This system is often used in industrial scenarios that require large-scale, continuous supply of high-purity water, such as electronic manufacturing, semiconductor industry, power industry, and pharmaceutical industry.

How does the EDI water treatment system work?

The core of the EDI water treatment system is to drive the ions in the water through an electric field and use a selective permeable membrane (i.e., ion exchange membrane) to remove the ions in the water. The whole process can be roughly divided into the following stages:

Pretreatment stage

Before entering the EDI unit, the water needs to be pretreated to remove suspended particles, organic matter, free chlorine, and most dissolved salts. Common pretreatment methods include sand filtration, activated carbon adsorption, softening, and reverse osmosis (RO) pretreatment. The main purpose of pretreatment is to protect the EDI unit from impurities clogging or damaging the ion exchange membrane, while improving the efficiency of the EDI and the quality of the produced water.

Ion migration and removal

In the EDI unit, the water flows through multiple compartments filled with ion exchange resins (commonly called mixed beds). The function of these resins is to capture cations and anions in the water. At this time, an external electric field is applied to the EDI module through electrodes, and the electric field causes the captured ions to be driven to the ion exchange membrane.

Ion exchange membranes include cation exchange membranes and anion exchange membranes. Cation exchange membranes only allow cations to pass through, while anion exchange membranes only allow anions to pass through. These membranes guide the migrated ions into the concentrate chamber, thereby separating the pure water from the ions. The excluded ions are guided out of the system through the concentrate chamber.

Continuous regeneration

Unlike traditional ion exchange equipment, the EDI system does not require the use of chemicals for the resin regeneration process. Under the action of the electric field, the regeneration of the ion exchange resin is continuous. The electric field drives the ions to migrate and discharge continuously, so the resin always remains active and can continuously remove ions. This design not only simplifies the operating process, but also reduces the use of chemicals and reduces the environmental burden.

Effluent treatment

The water treated by EDI usually reaches extremely high purity, with a conductivity as low as 0.1 µS/cm or less. This high-purity water can be directly used in industrial processes that require strict water quality control.

What are the components of the EDI water treatment system?

2000L/H EDI water treatment system consists of several key components, each of which plays an indispensable role in the entire system.

Ion exchange membrane

Ion exchange membranes are the core components of the EDI system. Their function is to allow specific ions to pass through while blocking the passage of other ions. Cation exchange membranes only allow cations to pass through, while anion exchange membranes only allow anions to pass through. The selectivity and durability of the membrane directly affect the performance and life of the system.

Ion exchange resin

Ion exchange resins are filled in the compartments of the EDI module to adsorb and exchange ions in water. The resin can be continuously regenerated by the action of the electric field, which is also a major advantage of the EDI system. The type and quality of the resin are crucial to the deionization efficiency of the system.

Electrode

The electrodes in the EDI system are used to generate an electric field. Typically, the system is configured with an anode and a cathode, which generate positive and negative electric fields, respectively. The material of the electrode is usually selected from materials with strong corrosion resistance and good conductivity, such as titanium-coated platinum or stainless steel.

Power control system

The power control system is used to regulate the voltage and current applied to the electrodes. The stability and control accuracy of the power supply directly affect the working efficiency and water quality of the EDI system.

Concentrated water circulation system

During the EDI process, the removed ions are exported from the system through the concentrated water chamber. In order to improve the efficiency of the system, the concentrated water is usually partially recycled back to the system for reprocessing. The concentrated water circulation system can reduce the waste of water resources while improving the overall water production rate.

Pretreatment unit

Although not directly belonging to the EDI module, the pretreatment unit is essential for the normal operation of the EDI system. Pretreatment units usually include sand filters, activated carbon filters, softeners, reverse osmosis devices, etc. These devices are used to remove large particle impurities, organic matter, hardness and free chlorine in water to protect EDI membranes and resins from contamination and damage.

What are the application scenarios of EDI water treatment systems?

In the electronic manufacturing process, such as semiconductor and display manufacturing, the purity of water directly affects the quality of the product. High-purity water is used in cleaning, chemical reactions and other processes, and any tiny ion contamination may cause product defects. EDI systems have become the first choice in this field because of their ability to continuously produce high-purity water.

The pharmaceutical industry has extremely high requirements for water quality, especially water for injection and water for lotions, which must meet extremely high purity standards. The EDI system can stably provide high-purity water that meets pharmaceutical standards to meet industry needs.

In thermal power plants and nuclear power plants, high-purity water is used for boiler feed water, cooling water and other links to prevent corrosion and scaling of boilers and equipment. The EDI system can provide a stable supply of high-purity water to ensure the normal operation of the power plant.

When conducting precision analysis and experiments, laboratories have extremely high requirements for water quality. The EDI system can provide laboratories with continuous and reliable ultrapure water to ensure the accuracy of experimental data and the reliability of experimental results.

What are the advantages of the EDI water treatment system?

The EDI system uses an electric field drive method to achieve continuous regeneration of resin without the use of chemical agents such as acids and alkalis. This not only simplifies the operating process, but also reduces the use of chemical agents, reducing operating costs and environmental impact. The EDI system can continuously produce high-purity water with stable and reliable water quality, which is suitable for industry applications with demanding water quality requirements.

In addition, since the EDI system does not require regular chemical regeneration, the maintenance workload is relatively small and the long-term operating cost is low. EDI systems are usually compact in design, occupy a small area, are simple and convenient to operate, and are suitable for installation and use in various industrial environments.