What machines are used in water treatment plants?

The main task of a water treatment plant is to purify and treat water sources to meet the standards for drinking water or industrial water. In this process, water treatment plants need to use a variety of professional machines and equipment to ensure that the water quality meets the corresponding standards.

This article will introduce in detail the main machines and equipment commonly used in water treatment plants and their functions.

What is the main process of a water treatment plant?

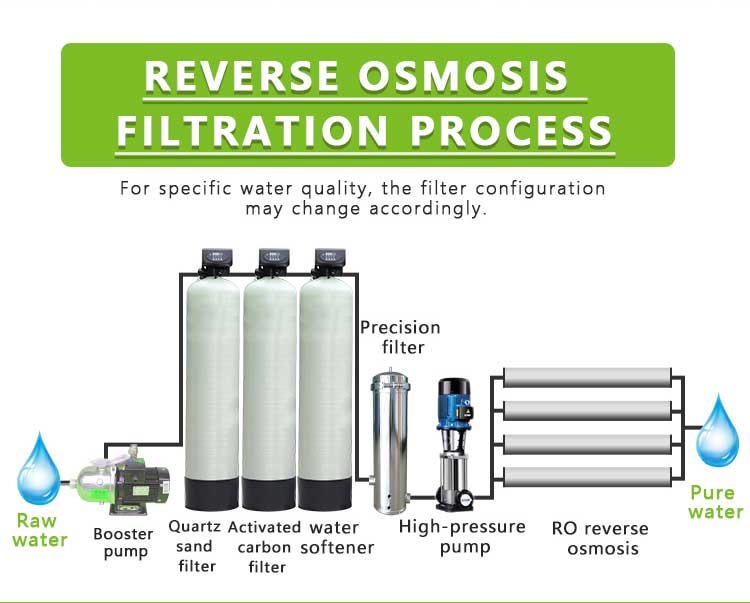

Before understanding the specific equipment, it is necessary to understand the basic treatment process of a water treatment plant. Generally speaking, the process of a water treatment plant includes the following main steps:

1. Water intake and pretreatment: Take water from a water source (such as rivers, lakes, groundwater), perform preliminary sedimentation and filtration, and remove large particles of impurities.

2. Coagulation and sedimentation: Add chemical agents to condense suspended particles into larger particles, and then precipitate and remove them.

3. Filtration: Further remove fine particles and impurities in the water through a filter tank or filter.

4. Disinfection: Use chlorine, ozone or ultraviolet rays to eliminate microorganisms in the water to ensure the safety of the water.

5. Storage and distribution: The treated water is stored in a water tank and delivered to users through a pipe network system.

What machines are used in water treatment plants?

1. Water intake and pretreatment equipment:

1.1 Water intake pump:

The water intake pump is the first equipment in a water treatment plant and is used to extract raw water from the water source. The water intake pump usually needs to have a high head and flow rate to ensure efficient water intake from different water sources. Common water intake pumps include centrifugal pumps, axial flow pumps and submersible pumps.

1.2 Screen:

The screen is used to remove large particles of impurities in the raw water, such as branches, garbage and large suspended matter. The screen is usually installed at the front end of the water intake pump to protect subsequent equipment from damage. The gap size of the screen can be adjusted according to the water quality.

1.3 Primary sedimentation tank:

The primary sedimentation tank is one of the key equipment for pretreatment, which removes suspended particles in the water by gravity sedimentation. A sludge scraper is installed in the primary sedimentation tank to regularly remove sludge deposited at the bottom of the tank.

2. Coagulation and sedimentation equipment:

2.1 Dosing device:

The dosing device is used to add coagulants and flocculants to the water, such as polyaluminium chloride (PAC), aluminium sulfate, etc. These agents can cause the fine suspended particles in the water to aggregate into larger particles, which is convenient for subsequent sedimentation and removal.

2.2 Mixer:

The mixer is used to evenly disperse the coagulant and flocculant in the water. Common mixers include static mixers and mechanical mixers. Static mixers rely on the turbulent effect of water flow for mixing, while mechanical mixers use mechanical stirring to achieve mixing.

2.3 Flocculation tank:

The flocculation tank is an important part of the coagulation process. The water treated by the mixer stays in the flocculation tank for a period of time to allow the coagulant to fully play its role and form larger flocs. The flocculation tank is usually equipped with a slow stirring device to maintain the stability of the flocs.

2.4 Sedimentation tank:

The sedimentation tank is used to remove the flocs formed during the flocculation process. The water stays in the sedimentation tank for a period of time, and the floccules settle to the bottom of the tank under the action of gravity. There is also a scraper in the sedimentation tank to regularly remove the sludge at the bottom of the tank.

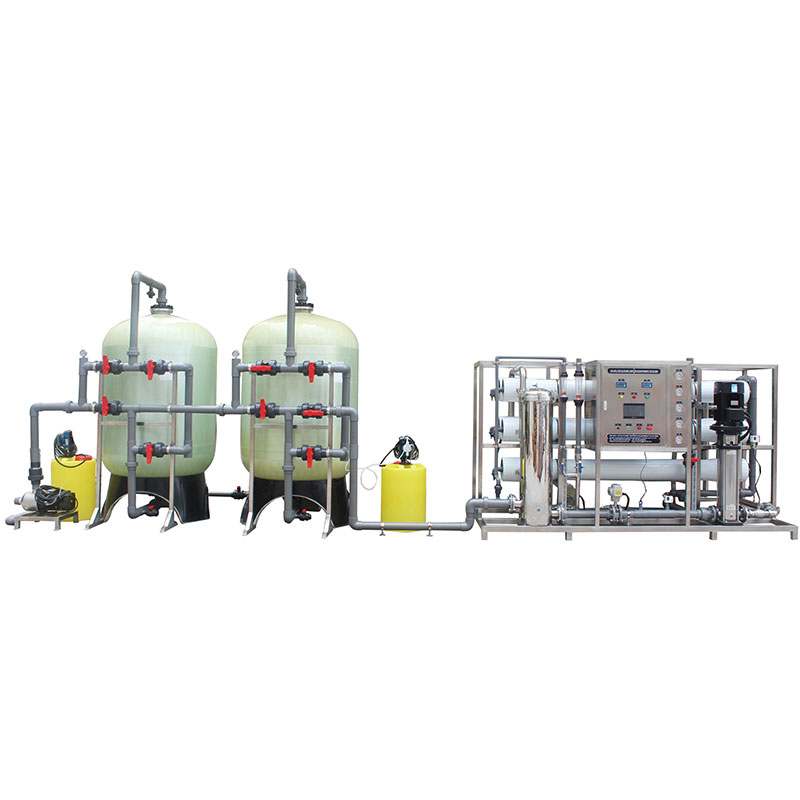

3. Filtration equipment:

3.1 Rapid filter:

Rapid filter is a commonly used filtration equipment in water treatment plants. It removes fine suspended particles in the water through a filter layer (such as sand and gravel). The filtration rate of the rapid filter is fast and suitable for large flow treatment.

3.2 Slow filter:

Slow filter removes suspended particles and some microorganisms in the water through low-speed filtration. The filter layer of the slow filter is usually thicker, and the filtration effect is better, but the processing speed is slower, which is suitable for small flow treatment.

3.3 Sand filter:

Sand filter is a common filtration equipment widely used in water treatment plants. Sand filter removes suspended matter and impurities in water through one or more layers of sand filter material. The advantages of sand filter are simple operation and convenient maintenance, and it is suitable for various water quality conditions.

4. Disinfection equipment:

4.1 Chlorine disinfection device:

Chlorine disinfection is one of the most commonly used disinfection methods in water treatment plants. Chlorine disinfection devices kill bacteria, viruses and other microorganisms in water by adding chlorine to the water. The advantages of chlorine disinfection devices are good disinfection effect and low cost, but the amount of chlorine needs to be strictly controlled to avoid excessive chlorine residue.

4.2 Ozone generator:

Ozone generator produces ozone by ionizing oxygen in the air. Ozone has strong oxidizing properties and can effectively kill microorganisms and organic matter in water. The advantage of ozone disinfection is that it does not produce harmful disinfection by-products, but the equipment cost is relatively high.

4.3 Ultraviolet disinfector:

Ultraviolet disinfector achieves disinfection effect by emitting ultraviolet rays to irradiate water flow, destroying the DNA of microorganisms in water. The advantage of ultraviolet disinfector is that it does not produce chemical residues, but the ultraviolet lamp needs to be replaced regularly.

5. Storage and distribution equipment:

5.1 Water storage tank:

The water storage tank is used to store treated clean water for subsequent distribution. The water tank needs to be cleaned and disinfected regularly to ensure that the water quality is not polluted again.

5.2 Water distribution pump:

The water distribution pump is used to deliver clean water from the water tank to the user end. The water distribution pump needs to have sufficient head and flow to meet the water needs of different users.

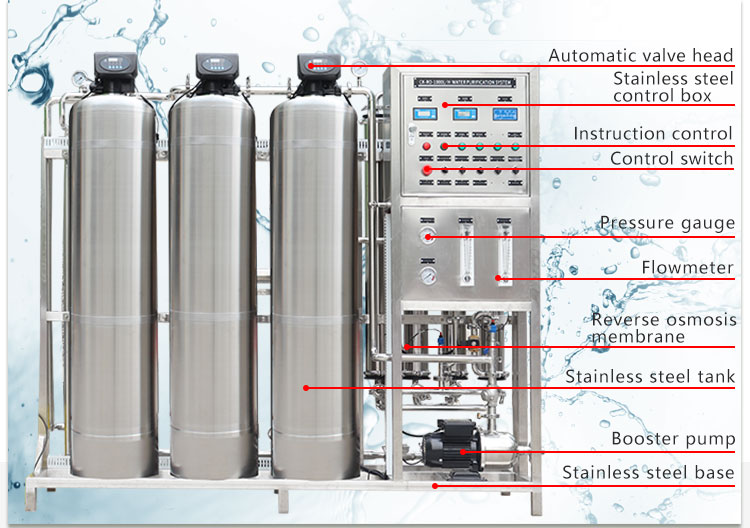

6. Control and monitoring equipment:

6.1 Automatic control system:

The automatic control system realizes automatic control of the water treatment process through sensors and controllers. The automatic control system can monitor water quality parameters (such as turbidity, pH value, residual chlorine, etc.) in real time, and adjust the treatment process according to the monitoring results to ensure stable water quality.

6.2 Online monitoring instruments:

Online monitoring instruments are used to monitor key parameters in the water treatment process in real time, such as turbidity meters, pH meters, residual chlorine analyzers, etc. The data of online monitoring instruments can help operators detect and deal with abnormal water quality in a timely manner.

Case Analysis

1. Shanghai Qingcaosha Reservoir:

Shanghai Qingcaosha Reservoir is one of the largest urban water sources in China. Its water treatment plant uses advanced treatment processes and equipment, including water intake pumps, screens, coagulation and dosing devices, flocculation tanks, rapid filters, chlorine disinfection devices, etc., to ensure the safety of drinking water for Shanghai citizens.

2. California Water Treatment Plant:

A large water treatment plant in California, USA, uses a fully automatic control system and online monitoring instruments to achieve full automation of the water treatment process. The water treatment plant is equipped with centrifugal pumps, sand filters, ozone generators, ultraviolet disinfectors and other equipment, and the effluent water quality is excellent, which has been widely recognized by users.

Conclusion

The water treatment plant achieves comprehensive treatment and purification of water quality by using various professional equipment. These equipment perform their respective duties and work together to ensure that the treated water quality meets the standards for drinking water or industrial water. The effective operation of the water purifier not only depends on the advancement of the equipment, but also requires scientific management and maintenance.