Two Stage RO System

Two Stage RO System

Chunke design reverse osmosis water purification system as regards to customer design. If you want to reduce wasting concentrated water quantity, we can apply two stage Ro system.

At II stage RO system feed water passes first stage ro membrane and get permeate (pure water) and concentrated water, this concentrated water sends to second stage ro membrane and you get again permeate from second stage ro system. This kind of system increase recovery rate for all of system.

TWO STAGE RO SYSTEM

Two Stage RO Systems and Double Pass RO Systems terms are mostly used wrong in industrial reverse osmosis water systems. First of all we understand of this term clearly.

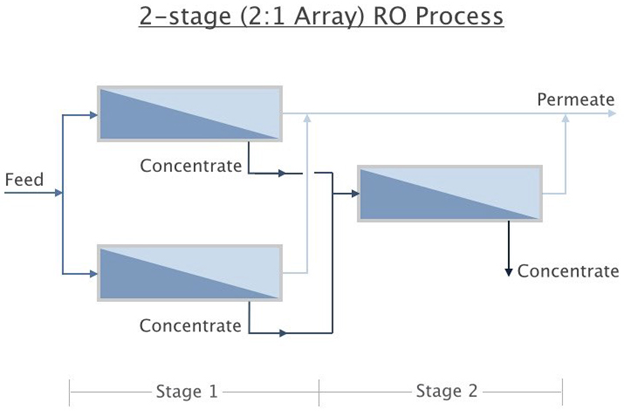

Focusing on spiral wound membrane modules as the most common type of membrane modules used in industrial water conditioning today, an RO array or “skid” or “train” consists of a number of pressure vessels arranged in specific patterns. Below figure shows an array of 3 pressure vessels for two stage ro system. The pressure vessels are arranged into 2 sets, with 2 pressure vessels in parallel followed by 1 single pressure vessel. The 2 sets of pressure vessels are in series. Each set of pressure vessels in parallel (even if there is only 1 vessel) is called a STAGE.

In theory, influent water to the industrial reverse osmosis water system is split evenly among the pressure vessels in the first stage. Permeate from each pressure vessel in the first stage is combined and collected in a common header. The reject from the first stage becomes the influent to the second stage for two stage ro system. Permeate from the pressure vessels in the second stage is collected and combined with permeate from the first stage to become the overall permeate from the industrial reverse osmosis water system. The reject from the second stage becomes the reject for the entire system.

As you see from two stage industrial reverse osmosis water system, concentrated water is passing membrane system again, in double pass system, pure water passes membrane system again.

Here we explain just reverse osmosis side for industrial water conditioning, of course pretreatment side as optional has sand, activated carbon, anion exchange water treatment, softener…etc for two stage ro system.

Anion exchange water treatment softener or cation exchange water treatment can help to get soft water at industrial water conditioning applications. Pretreatment side especially anion exchange water treatment filters and cation exchange water softeners do not affect TDS readings significantly in industrial reverse osmosis water systems.

Industrial water conditioning include pretreatment, ultra-filtration, reverse osmosis, anion exchange water treatment, ion exchange softeners, post treatment modules. Which models we use; we can decide as regards to your water analysis report and application.

To get more info about anion exchange water treatment as industrial water conditioning, please see our water softener and EDI system details.