What is integrated water treatment machinery?

In the context of today's increasingly serious water shortage and pollution problems, the development of water treatment technology is particularly important. With the advancement of science and technology and the enhancement of environmental awareness, integrated water treatment machinery has emerged and has been widely used in many fields. So, what is integrated water treatment machinery? What are its advantages? This article will explore this topic in detail.

What is integrated water treatment machinery?

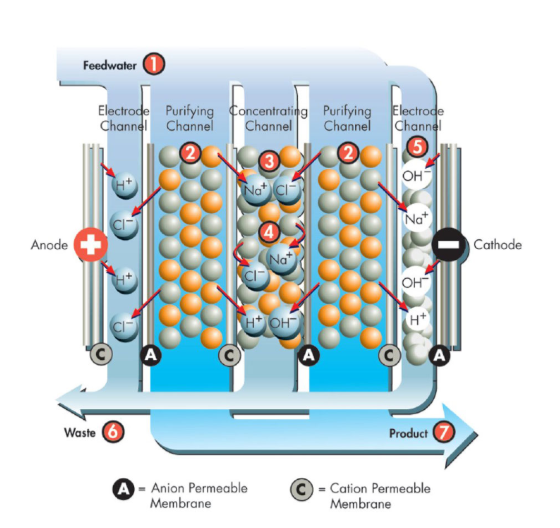

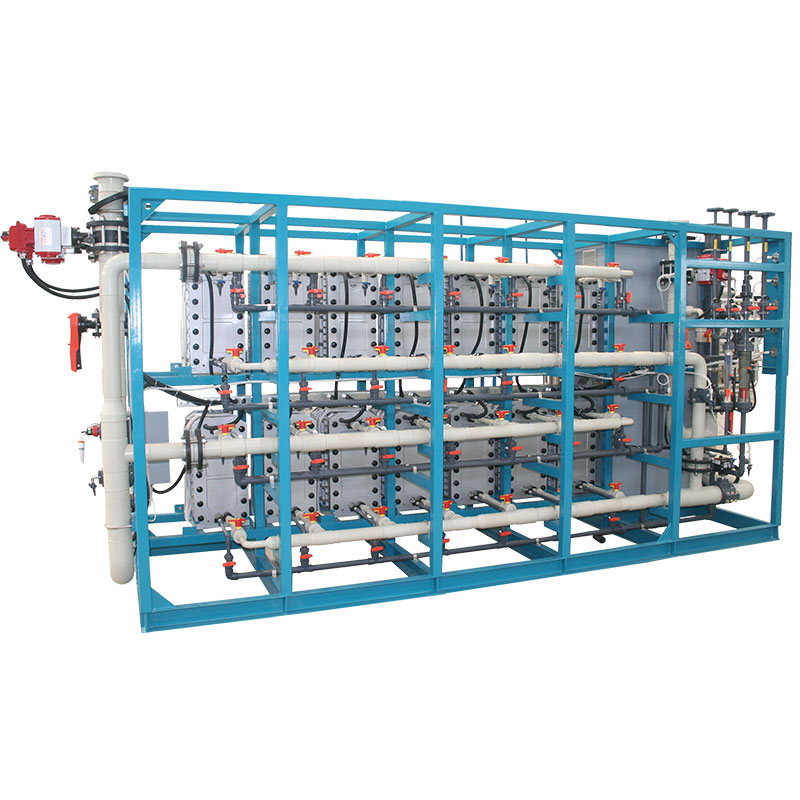

Integrated water treatment machinery, as the name suggests, integrates various functional modules of water treatment into one device or system, and purifies and treats water quality through a combination of multiple treatment processes. Traditional water treatment systems usually consist of multiple separate devices, which are connected by pipes and control systems. Integrated water treatment machinery modularizes these functions and integrates them into a compact device.

Integrated water treatment machinery usually includes multiple functional units such as pretreatment, filtration, sedimentation, disinfection, sludge treatment, etc., and adopts different process combinations according to specific water treatment needs, such as flocculation sedimentation, activated carbon adsorption, ultrafiltration, reverse osmosis, ultraviolet disinfection, etc. This integrated design not only simplifies the system structure, but also improves the overall efficiency and ease of operation of the equipment.

What are the main components of integrated water treatment machinery?

Pretreatment unit:

The pretreatment unit usually includes a screen, a grit chamber and a regulating tank, which are used to remove large particles of impurities, sand and suspended matter in the water to ensure the smooth progress of the subsequent treatment process.

Coagulation and sedimentation unit:

By adding coagulants and flocculants, the colloidal particles and suspended matter in the water are condensed into larger flocs and separated through a sedimentation tank. This unit plays an important role in solid-liquid separation in water treatment.

Filtration unit:

Common filtration methods include sand filtration, activated carbon filtration, ultrafiltration, etc. The filtration unit is used to remove fine suspended matter, organic matter, microorganisms and odors in the water to further improve the water quality.

Disinfection unit:

Disinfection is an important step in water treatment. Common disinfection methods include chlorine disinfection, ozone disinfection and ultraviolet disinfection. The disinfection unit can effectively kill pathogens in the water and ensure the hygiene and safety of the effluent.

Sludge treatment unit: Integrated water treatment machinery is usually equipped with a sludge treatment unit to concentrate, dehydrate, and properly dispose of the sludge generated during the treatment process to reduce environmental pollution.

What are the advantages of integrated water treatment machinery?

Integrated water treatment machinery has many significant advantages due to its unique design and functional integration. Here are some of the key advantages:

Small footprint:

Traditional water treatment systems usually require a large amount of space to house each independent treatment equipment. Integrated water treatment machinery greatly reduces the footprint of the equipment by integrating multiple treatment functions into one device, which is particularly suitable for factories, rural areas and remote areas with limited space.

Easy installation:

Integrated water treatment machinery usually adopts a modular design. After the equipment arrives at the site, it only needs simple assembly and connection, without complex infrastructure construction and pipeline laying. Compared with traditional systems, the installation process of this equipment is more convenient and faster, which can significantly shorten the construction period and reduce construction costs.

Simple operation and maintenance:

Integrated water treatment machinery is usually equipped with an automated control system, which realizes fully automatic operation through a PLC (programmable logic controller) or a remote monitoring system. The operator only needs to perform simple parameter settings and monitoring, and the equipment can automatically complete the water treatment process. At the same time, the equipment has a compact structure, each unit has a high degree of integration, and daily maintenance and overhaul are more convenient.

High treatment efficiency:

Since each treatment unit is seamlessly connected inside the equipment, the treatment efficiency of the integrated water treatment machinery is higher than that of the traditional system. Especially when the treatment volume is large, the equipment can maintain a stable effluent water quality to ensure that the water treatment effect meets the expected standards.

Strong adaptability:

The integrated water treatment machinery can flexibly adjust the internal treatment process and parameters according to the water quality and treatment requirements. For example, for the treatment of industrial wastewater with complex water quality, the equipment can effectively remove different pollutants by adding or adjusting the treatment units. This flexibility makes the equipment suitable for various water quality conditions and treatment requirements, and the application range is very wide.

Environmental protection and energy saving:

Since the integrated design reduces the physical connection and energy loss between the equipment, the integrated water treatment machinery usually has a higher energy efficiency ratio. In addition, some integrated equipment also has the functions of sludge reduction and resource utilization, which further reduces waste discharge and environmental pollution.

High cost-effectiveness:

The integrated water treatment machinery has significant advantages in construction and operation costs. Due to the high degree of equipment integration, the procurement and installation costs of multiple separate equipment are reduced. At the same time, the application of automated control systems reduces labor costs and energy consumption, further improving cost-effectiveness.

What are the application areas of integrated water treatment machinery?

Rural sewage treatment:

In rural areas, decentralized sewage treatment has become a challenge due to weak infrastructure. The compact design and efficient treatment capacity of integrated water treatment machinery make it an ideal choice for rural sewage treatment. The equipment can be flexibly arranged near the village to treat domestic sewage, agricultural wastewater, etc.

Industrial wastewater treatment:

Integrated water treatment machinery is also widely used in industrial wastewater treatment, especially in the chemical, pharmaceutical, and food processing industries. The equipment can select the appropriate treatment process according to the type and concentration of pollutants in the wastewater to ensure that the wastewater meets the discharge standards.

Municipal water treatment:

In the municipal field, integrated water treatment machinery is often used for emergency water supply, temporary water supply, and tap water supply in remote areas. The equipment can be deployed quickly to ensure the provision of safe drinking water in emergencies.

Construction sites and field operations:

Integrated water treatment machinery is also widely used in temporary work sites such as construction sites, mines, and oil fields. The equipment is highly mobile and can provide standard water in a short time.