Boiler Water Treatment Systems

Boiler Water Treatment Systems

In order to save energy cost in power and energy industry, Chunke have solution for boiler water treatment systems.

Chunke Boiler Water Treatment Systems remove all impurities and hardness and you do not face clog or scaling problem at your boilers or heat ex-changers.

For this purpose, reverse osmosis water purification, ion exchange water softeners and electrodeionization system help to solve your water problem.

BOILER WATER TREATMENT SYSTEMS

Chunke has special system for industrial water treatment for boilers and heat ex-changers. Most of factory to save cost they want to use deep-well, borehole water in their business and they want to use less boiler water chemicals. But this kind of water or tap water have some minerals which make water hard. Also, some other solid species result clog pipe or cover boiler tank’s wall so it creates big problem and reduce your efficiency. Some of customer solve this problem with boiler water chemicals, it solves some of problems but in long term increase cost. Boiler water treatment becomes one of the important parts of industrial engineering.

Boiler water treatment is the conditioning and treatment of boiler feed water with the purpose of meeting three objectives. In order for boiler water treatment to be maintained, there must be a continuous heat exchange, protection for high-quality steam, and corrosion protection. Boilers are designed to heat fluid, after which the vaporized or heated fluid will exit the boiler and be used for heating applications and various industrial processes like sanitation and cooking. The main types of industries that use boilers include the pharmaceutical, textile, steel, and chemical industries. When you use boiler water treatment system, you can use less boiler water chemicals and it helps you to reduce chemical cost. Boiler water chemicals usage can be more if you do not use boiler water treatment system.

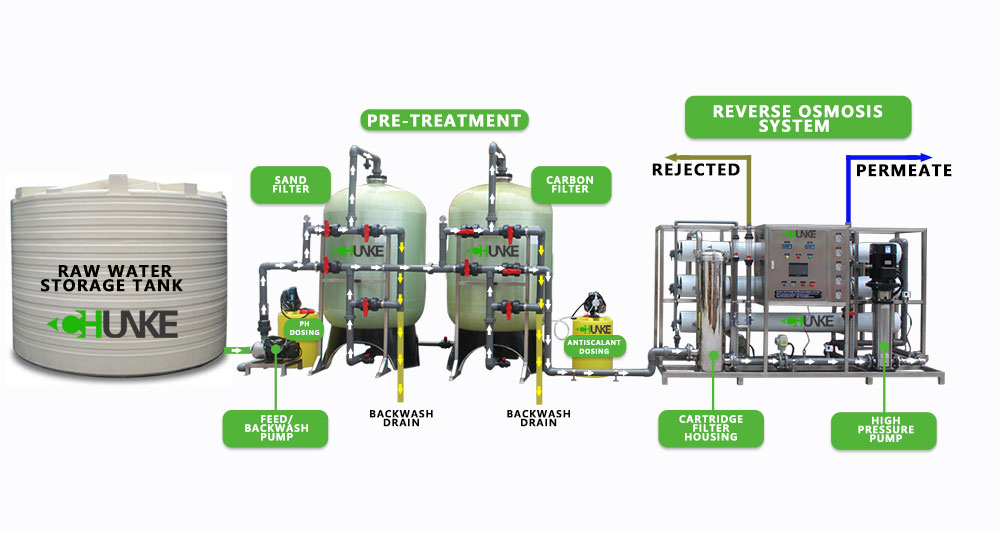

Our industrial water treatment for boiler systems consists of water pre-treatment including water filtration and water softening, reverse osmosis water purification systems, electrodeionization edi water treatment systems, boiler water chemicals, post treatment units.

After you get your raw water analysis report, our experienced engineers are checking and design most suitable industrial water treatment system for boilers and heat ex-changers. Boiler water treatment system design need knowledge and experience.

Below, you can see some of our cases for industrial water treatment for boilers. Typical industrial reverse osmosis water treatment system diagram as follows.

Industrial Water Treatment For Boilers

Boiler water treatment first step is Filtration is the mechanical removal of suspended solids from a fluid by means of a pressurized flow through a permeable medium. The amount and size of particles removed is based on the type of filtration media. Consider that clarification takes out the larger solids from the water. Filtration then removes more of the remaining suspended solids from the water. The degree of removal of the suspended solids is based on the size, type, and design of the filter.

Industrial water treatment for boilers second step is softening, Ion exchange is the substitution of ions in the water for ions that are attached to the resin bead. The type of resin bead used in this method of water conditioning dictates the ions that will be available in the water that enters the boiler.

The third step of industrial water treatment system is ro water purification. Reverse osmosis is a pressure-driven process used to remove dissolved ions from the feed water by the use of semipermeable membrane. The resultant is approximately 98% removal of the salts found originally in the water. The permeate is the water that has been processed through the RO membrane, which contains approximately 2% of the original solids level. The reject is the concentrated solution containing the rejected salts and the quantity of water that did not process through the membrane at industrial water treatment for boilers system.

The fourth step for industrial water treatment for boiler system is electrodeionization EDI water treatment, if it is necessary. EDI systems remove ionized and ionizable species from water using electrically active media and electrical potential (DC power) to affect ion transport. By using this type of purification technology, caustic and acidic types of chemicals are not required. The water which has been treated by RO-EDI has typically exceeded customer’s high-purity standards.