Water Softener Systems

Water Softener Systems

Reverse Osmosis softener systems are used to treat RO in-fluent water to remove soluble hardness (calcium, magnesium, barium, and strontium) that can form scale on RO membranes.

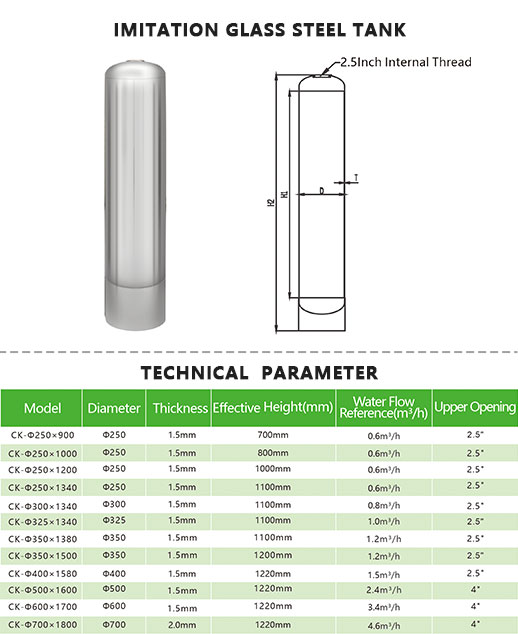

We have special ion exchange water softener tanks to remove hardness from raw water. This tanks material depend on raw water TDS and application can be FRP, Carbon Steel, Stainless Steel 304 and Stainless Steel 316. And also size of the tank designed with flow ratio.

WATER SOFTENER SYSTEMS

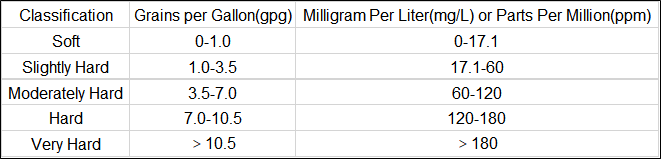

In scientific terms, water hardness is generally the amount of dissolved calcium and magnesium in water. If you check below table hardness as ppm or GPG, you can understand that you or your process need ion exchange water softener.

Hardness can affect human health, process sustainability, end product quality in your home or application. So if you want to remove or reduce hardness, you should use reverse osmosis water softener system at your water treatment plant. Especially hardness can clog pipes and if you have boiler, heat ex changer, it reduces efficiency and increase energy cost. Boiler water softener system also can be use separately if your water is clean and you just have water hardness problem.

Industrial ion exchange water softener make water soft by removing hardness using resin. The resin replaces the hardness in the water with salt which is regenerated periodically. The softened water can then pass through an RO system to remove the salt without the risk of scaling. Reverse osmosis softener system can be used in a variety of services including: industrial, municipal, and institutional applications.

An Industrial reverse osmosis softener system is sized on the basis of two different parameters:

Exchange capacity - which is the quantity of water delivered between regenerations, and it depends upon the amount of ion exchange resin in the softener and quantity of salt used for resin regeneration.

Maximum flow rate - which is the maximum quantity of water required at any peak usage period, and is an important datum in case of non-continuous water delivery and is measured in gallons per minute (GPM) for reverse osmosis softener system.

Material of Reverse Osmosis Ion Exchange Water Softener

· Carbon steel, Stainless Steel 304/316 or FRP resin tank

· Food grade interior epoxy coating

· Face piping: PVC/CPVC or galvanized steel or Stainless Steel

· Internal distributors: PVC/CPVC/Stainless Steel

· Control valves: Noryl or steel

· Brine Tank: Polyethylene, plastic internals

Operating Specification of reverse osmosis softener system

· Inlet Pressure: 2-7 bar

· Temperature: 2-42°C

· Feed water should not exceed 3,000 ppm TDS

· Service flow rates/ranges based on the m3 of the tank/filter bed

· Slower flow rate per m3 = better filtration

Applications for an ion exchange water softener include:

· Apartments/Condominiums

· Groundwater remediation

· Hospitals

· Laundries

· Boiler Water Softener

· Contact process water

· Car Washes

· RO Pretreatment

· Well Water

Softener system also can be use separately from reverse osmosis softener system. You can just install softener tank and reduce your water hardness. Ion exchange water softener just need resin tank and brine tank for regeneration of ion.

Some water source has very high level of Ca, and it makes boiler inside white color film. Boiler water softener can reduce hardness and does not allow getting this film. But for boiler application, just use boiler water softener maybe can not effective, because of evaporation, TDS can be increase and it can be corrosive. Boiler water softener in ro system is the best solution for boiler application.