UV Sterilizer

UV Sterilizer

The source of UV radiation is mercury vaporization; this phenomenon was discovered in 1835 and in 1901 the mercury vapor lamp was developed. The first application of UV for disinfection of drinking water was in

Marseilles, France in 1910; the system was not reliable due to its complicated technology and was not used since ozone came on the scene in Europe, along with chlorine in the United States.

UV STERILIZER FOR WATER DISINFECTION

Ultraviolet (UV)light represents a band of electromagnetic light in the100–400nm range. UV Sterilizers or ultraviolet UV Disinfection is a non-chemical disinfectant process that uses a very short contact time (<5s). UV light issued to break specific chemical bonds, sometimes by direct photolysis, but usually by the creation of highly reactive hydroxyl (OH-) radicals. Photolysis applications include dechlorination, de-ozonation, removal of TOC and more recently to counter the threats caused by endocrine disruptors and pharmaceutical compounds (both metabolized and un-metabolized).

Ultraviolet UV disinfection and UV sterilizers, for microbial destruction and water disinfection, 254 nm UV energy is used, whereas shorter (and more powerful wavelength) electromagnetic radiation, 185 nm UV energy, is used to reduce organic compounds and chlorine destruction. The energy of UV sterilizer’s light beam is inversely proportional to the wavelength. Thus, 185 nm UV irradiation carries more energy and is more powerful than the 254 nm light; 185-nm energy oxidizes total oxidizable carbon (TOC) to form carbon dioxide and water. Most microorganisms are damaged at a UV irradiation dosage level of 10,000–30,000 μW-s/cm2, whereas the dosage level required for reducing ozone, chlorine and TOC reduction is 90,000 μW-s/cm2.

Ultraviolet UV Disinfection process is used most of application specially food, beverage, drinking water and pharmaceutical industry. Water disinfection process is important to keep water contaminants. UV sterilizers size and futures as below.

UV Sterilizers water disinfection models

Model | Flow | Power | Dimension | Inlet/Outlet size | MaxOperation Pressure |

CK-UV005G | 0.5GMP(0.1T/H) | 8W | L250*W48*H65mm | 1/4" | 0.8Mpa |

CK-UV01G | 1GMP(0.2T/H) | 10W | L290*W60*H80mm | 1/4" | 0.8Mpa |

CK-UV02G | 2GMP(0.5T/H) | 14W | L370*W60*H85mm | 1/2" | 0.8Mpa |

CK-UV04G | 4GMP(1.0T/H) | 17W | L450*W73*H110mm | 1/2" | 0.8Mpa |

CK-UV06G | 6GMP(1.3T/H) | 23W | L520*W73*H110mm | 3/4" | 0.8Mpa |

CK-UV08G | 8GMP(1.8T/H) | 28W | L650*W73*H110mm | 3/4" | 0.8Mpa |

CK-UV12G | 12GMP(2.7T/H) | 40W | L950*W73*H110mm | 1" | 0.8Mpa |

CK-UV15G | 15GMP(3.5T/H) | 80W | L950*W73*H110mm | 1" | 0.8Mpa |

CK-UV3T | 3T | 40W*1 | L950*W125*H250mm | 1" | 0.8Mpa |

CK-UV4T | 4T | 80W*1 | L950*W125*H250mm | 1.2" | 0.8Mpa |

CK-UV5T | 5T | 40W*2 | L950*W138*H280mm | 1.2" | 0.8Mpa |

CK-UV6T | 6T | 40W*2 | L950*W140*H280mm | 1.5" | 0.8Mpa |

CK-UV8T | 8T | 40W*3 | L950*W160*H310mm | 2" | 0.8Mpa |

CK-UV10T | 10T | 80W*2 | L950*W180*H310mm | 2" | 0.8Mpa |

CK-UV12T | 12T | 40W*4 | L950*W215*H335mm | 2" | 0.8Mpa |

CK-UV15T | 15T | 40W*5 | L950*W215*H335mm | 2" | 0.8Mpa |

CK-UV20T | 20T | 80W*3 | L950*W215*H385mm | 2.5" | 0.8Mpa |

CK-UV25T | 25T | 80W*4 | L950*W275*H465mm | 2.5" | 0.8Mpa |

CK-UV30T | 30T | 120W*3 | L1300*W275*H465mm | 3" | 0.8Mpa |

CK-UV40T | 40T | 120W*4 | L1300*W275*H465mm | 3" | 0.8Mpa |

CK-UV50T | 50T | 120W*5 | L1300*W275*H485mm | 4" | 0.8Mpa |

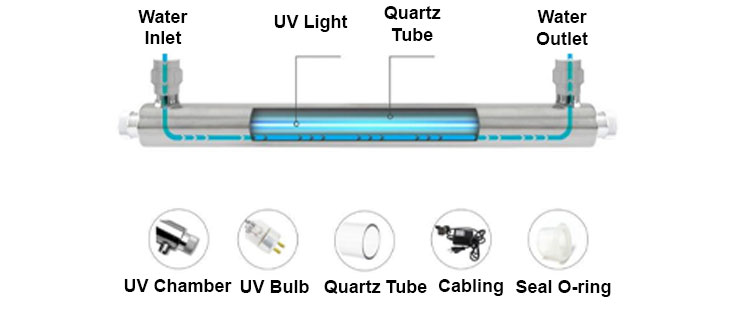

UV water disinfection or UV sterilizers systems generally consist of a reactor with a number of lamps that emit ultraviolet UV disinfection radiation. Each lamp is encased in a quartz tube. Ultraviolet UV Disinfection products are built to be cost-effective, simply installed, and tested to guarantee quality water to the highest degree.